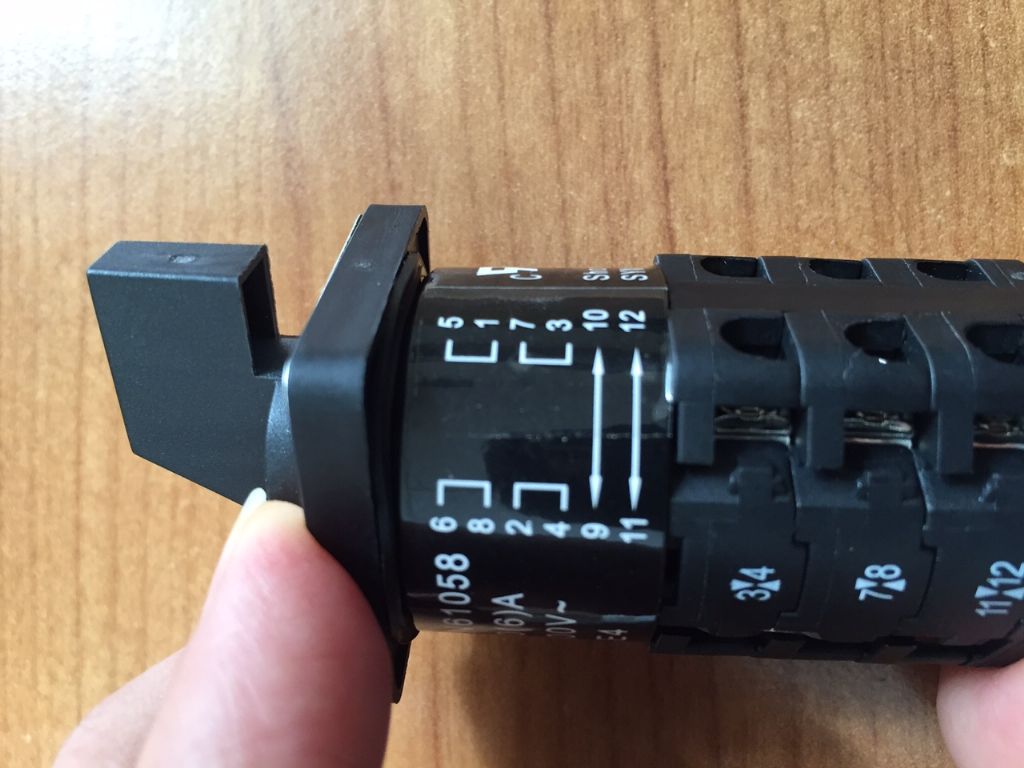

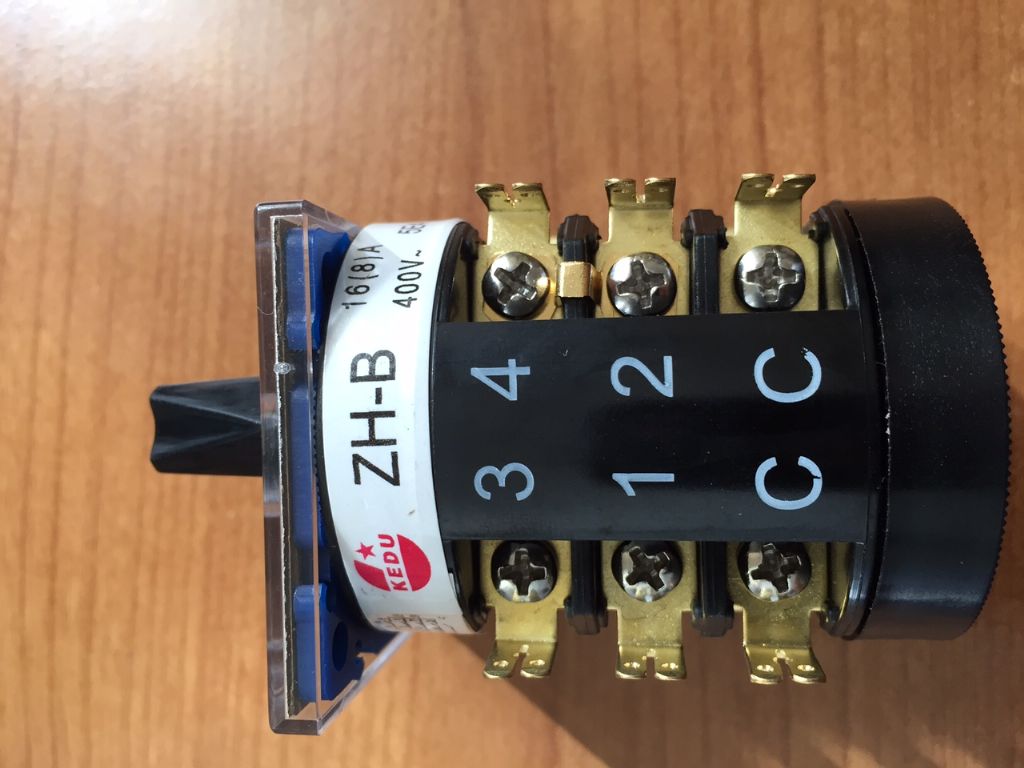

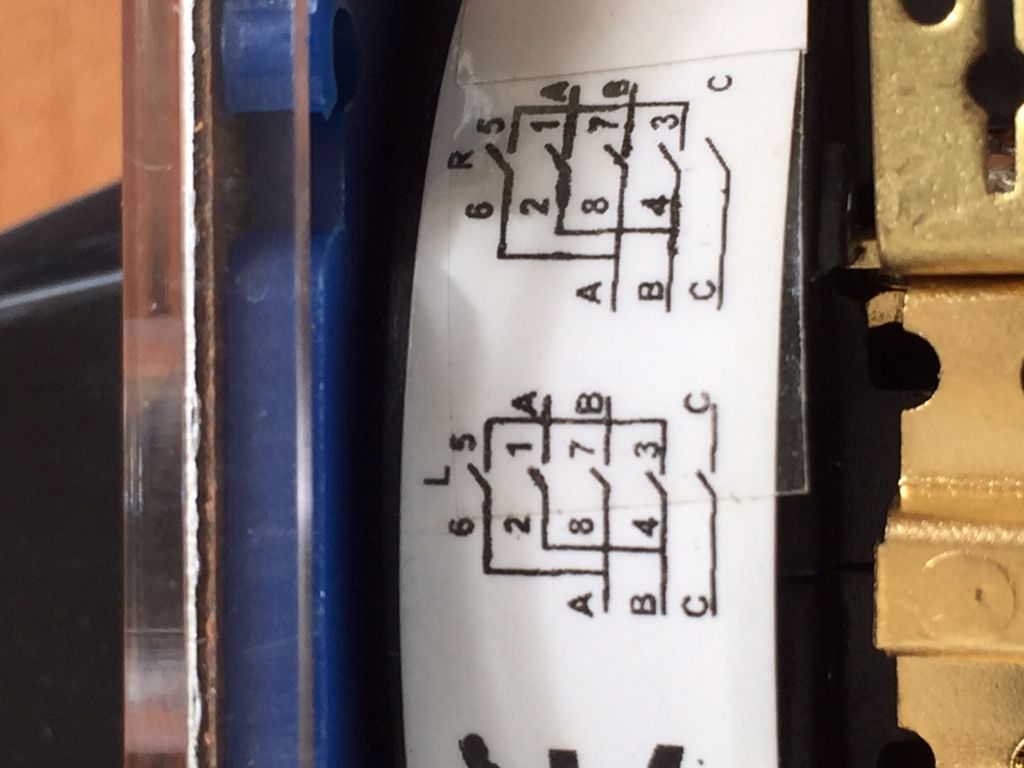

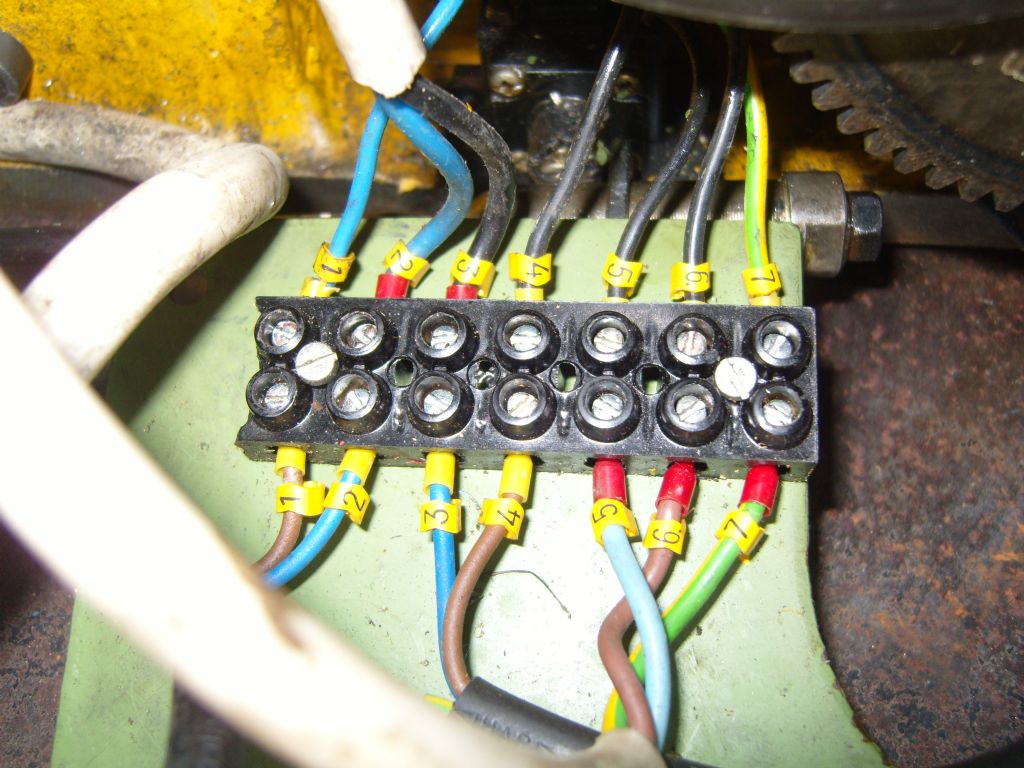

Hi Les and Kevin, Les your mention of the interlock switches has prompted me in thinking that my original belief that the flex on Kevin's lathe that went into the original contactor box has been changed, because looking at his second photo down of his F/R switch and the connection block, there seems to be a lack of wires connected into it. It seemed to be a bit empty compared to mine but nothing has dawned on me before, my connection block has all the interlock wires connected into it and the flex coming from the contactor box is a five core one, containing three black wires, one blue and a green/yellow.

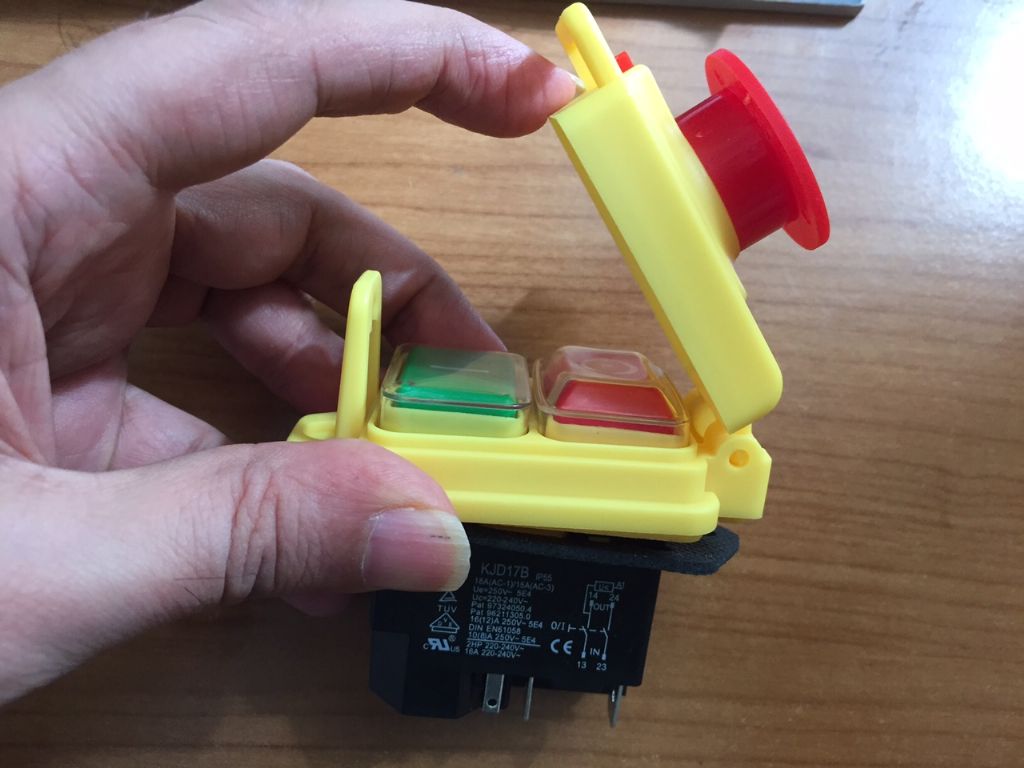

On the top row Nos. 1 and 4 are the interlock wires that trip the contactor, Nos. 2 and 3 are from the emergency stop at the tailstock end of the lathe bed, Nos. 5 and 6 are live and neutral from QF1 and 7 is earth.

On the bottom row Nos. 1 and 2 are the chuck guard switch, Nos. 3 and 4 are the gear/belt cover switch and Nos. 5, 6 and 7 go to the F/R switch. In the photo below can be seen the switch that is operated by opening the gear/belt cover acted by the rod that runs along the bottom and is anchored in the bracket of cover at the left hand side. The black flex behind the V belt goes up to the chuck guard switch,

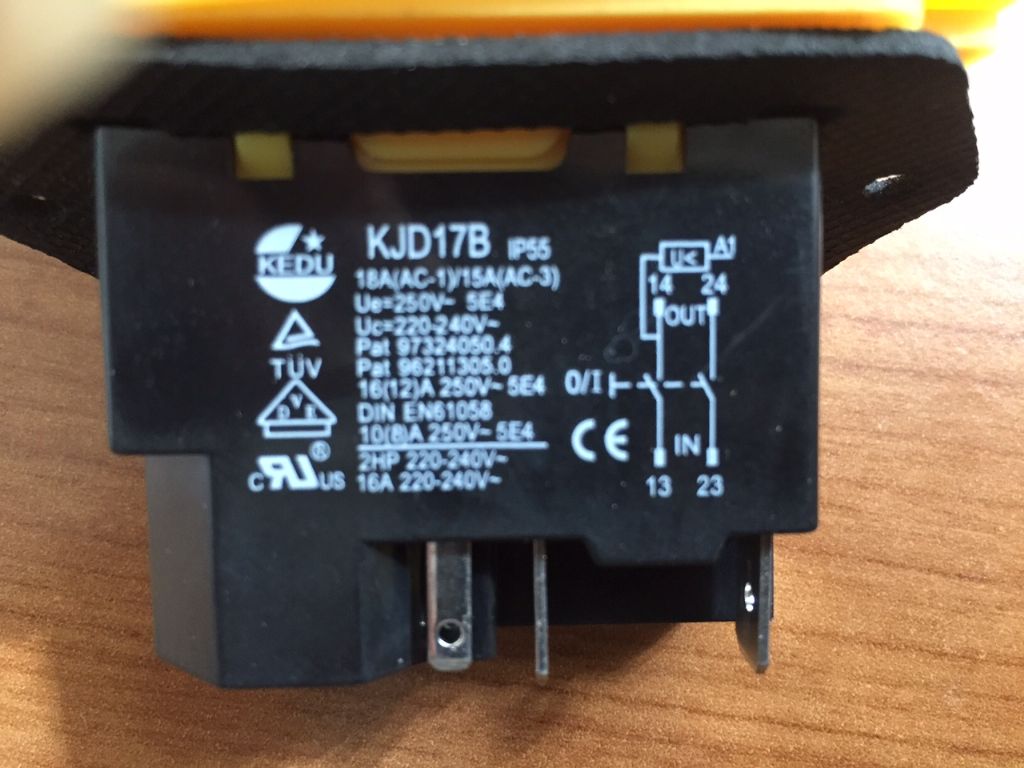

I don't know if Kevin's emergency stop actually works, but if it does, it probably only cuts the live side and if it is reset without the F/R lever returned to the stop position, the lathe will restart straight away, which is very dangerous. I don't see any evidence of a chuck guard of gear/belt cover switch on Kevin's lathe, so interlocking will be very limited, might be a good idea if Kevin checks for any switches of any kind.

Regards Nick.

Edited By Nicholas Farr on 15/04/2015 18:39:53

Raymond Sanderson 2.