Posted by Mark Simpson 1 on 07/02/2019 11:41:16:

Hi

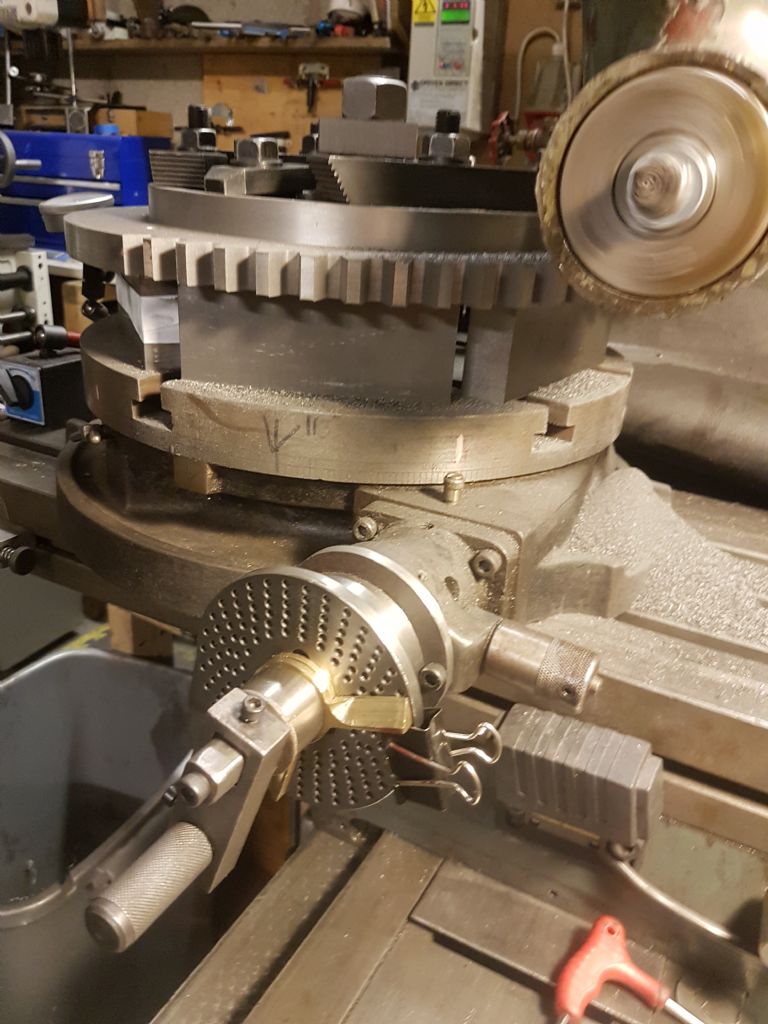

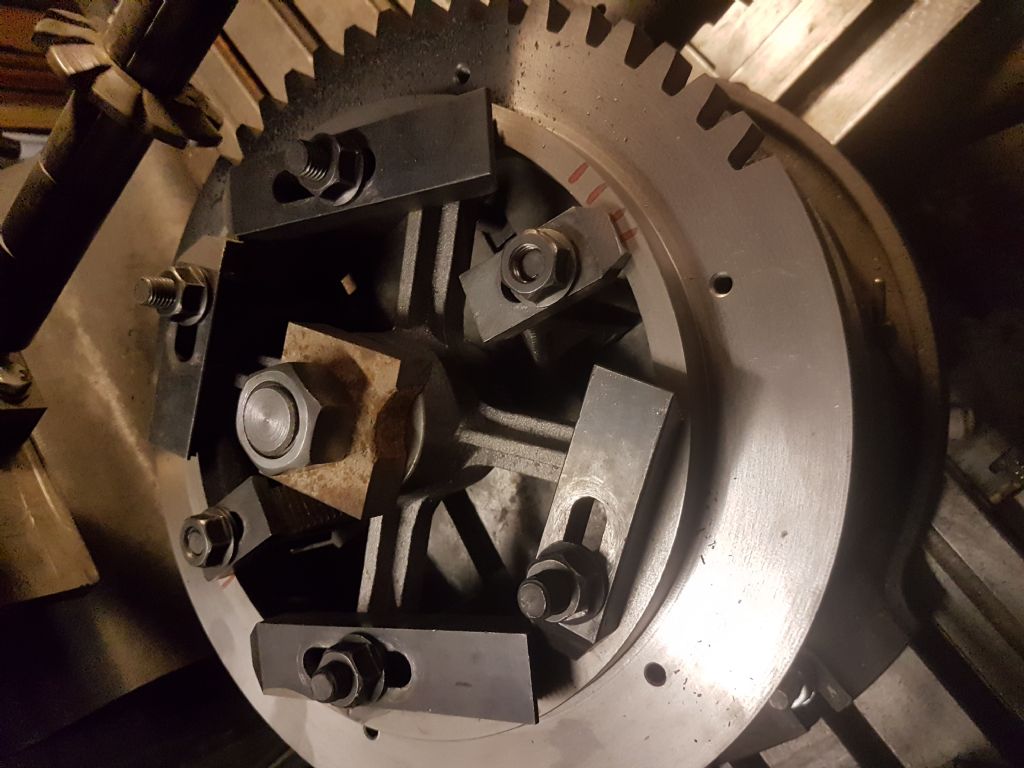

I've a 15" rotary table 90:1 to which I need to add a means of dividing for 55,66, and 76 (for spur gear cutting)

it currently has no dividing gear so I have to build something…..

I've also a 6" elliott dividing head with one plate, which I've successfully used to cut a couple of smaller spur gears.

Reading this thread and others it seems most sense to build a stepper motor dividing system than I can switch between both…. I guess Steve (world of ward) wards controller, or the Arduino one Like Carl Wilson in issue 249 would now be the logical place to start; no problem with either (I think)

The resource I cannot find is about Stepper Motor Specification..My 15" table is a lot bigger than a 6" vertex, especially with a 19.5" gear on it. Is a Nema 23 1.8Nm stepper enough? Should I gear it down with T?? pulleys/belt(might also make get the drive to a better location

Any suggestions/tips really welcome

Thanks Mark

How difficult is your 15" table to turn compared with the 6"? Unless the 15" is much stiffer (perhaps when heavily loaded), I'd expect a 1.8Nm to turn it well enough. The motor only has to provide as much torque to the table drive as a human does when turning the hand-wheel, probably not much. If the table is very stiff you could measure the torque needed to turn it and buy a motor to suit. (Ask again if you need to measure torque.)

Carl's divider as described in his MEW article uses an Arduino and software developed by Gary Limings. The display and keyboard are a standard module. Provided you have a computer it's easy (and free) to install Gary's program on the Arduino and the electronics are a straightforward wiring job. A limitation of the keyboard module is that it only provides 5 buttons, making it necessary for the operator to navigate a nested menu structure, which some find annoying or hard to remember.

Steve Ward's divider uses a 4×4 keypad and a PIC controller. Full build and user instructions on the web. It doesn't need the nested menus that make the Liming's software a little clunky to use. However, installing programs on a PIC is rather more complicated than the same job on an Arduino and the electronics are also more work, though I believe they are available as a kit. PIC is not outrageously more complicated than Arduino but the Arduino family – hardware and software – benefit from several features designed to make them beginner-friendly.

Banging my own drum, following a challenge from the late great John Stevenson who disliked nested menus, my effort uses an Arduino, an I2C LCD display (standard item), and a 4×4 keypad. No nested menus, and – like Steve Ward's divider – more natural operation. It is not a clone. Main problem is that the documentation is unpolished – I was going to write it up as an article but felt it was too soon after Gary's to have any appeal. An undeveloped feature that might be useful is that the divider can be controlled by a remote computer over a serial interface; the client software would have to be written by the user. In stand-alone mode everything works and it's been built by at least two others apart from me. Details here if anyone is interested, the latest version is in the folder 'keypad_i2c'

Dave

Mark Simpson 1.

if I am careful. Those errors would (I guess) tend to magnify up to the outer diameter where the teeth are (so perhaps .003" at 19.5" diameter)… It's a traction engine so not high speed, no idea if .003" possible deviation on tooth width is acceptable

if I am careful. Those errors would (I guess) tend to magnify up to the outer diameter where the teeth are (so perhaps .003" at 19.5" diameter)… It's a traction engine so not high speed, no idea if .003" possible deviation on tooth width is acceptable