Posted by Martin Cargill on 09/03/2019 11:13:10:

Nobody yet has mentioned the idea of clamping a piece of bar in the chuck before you remove it. It gives you a "handle" sticking out of either side of the chuck to make lifting easier. It also allows you to push the back end of the bar into the headstock and then lift the front to get the chuck started onto the LO taper.

Martin

This sounds like an improvement on my own method referred to above in which the bar projects from the back of the chuck only and the chuck is gripped directly by the operator. The disadvantage of a "handle" on both sides for me, however, is that I like to store my chucks resting on their jaws. I use a stout wooden bar, rather than steel, which minimises the extra weight introduced by the "handle".

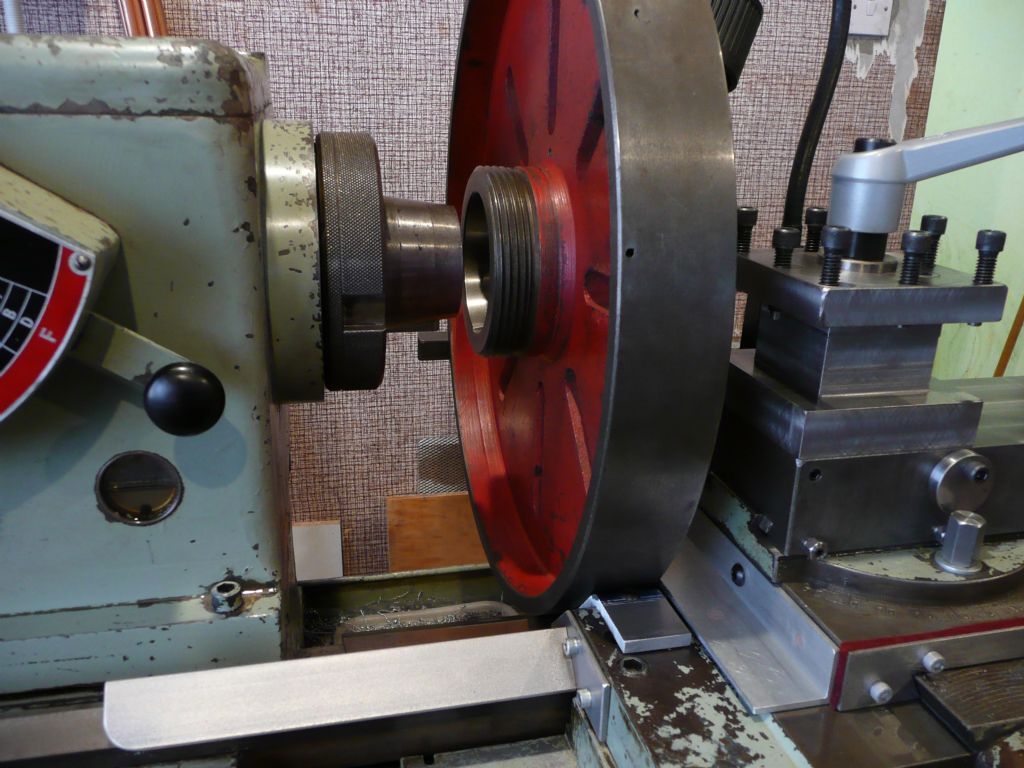

Large faceplates can be a challenge, too, particularly if they are being mounted in a gap bed. The Willson's slant bed allows its cumbersome 16" faceplate to be suspended between the edge of the saddle and a length of angle temporarily bolted across the back of the cross slide before being slid on or off the spindle:

ega.