Anthony

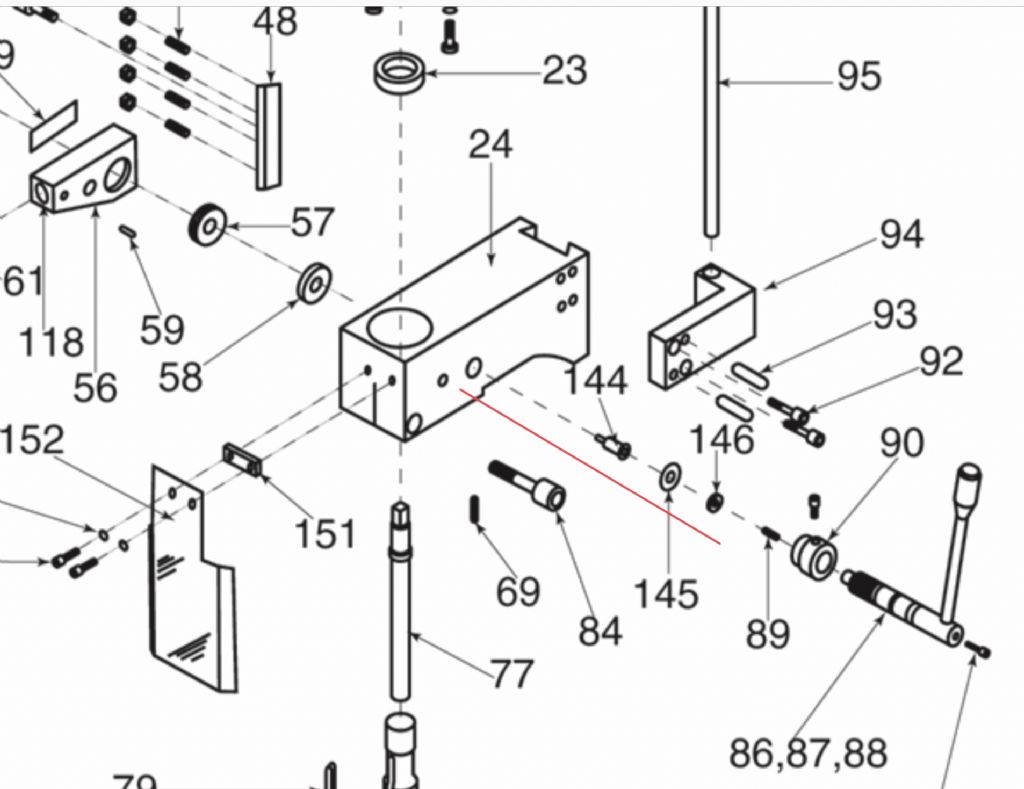

I recently purchased one of these and it's still shiny & new but yours looks as if it's seen a bit of service. Working on the premis that both our machines are identical and there haven't been any upgrades/changes, number 1 is actually two seperate things.

As Frances notes, the flat plate held with 2 small setscrews, is a load spreading plate for the annoying plastic guard. It serves no other purpose other than to prevent the screws digging in to, and weakening, the plastic guard.

The other part (the recessed M8) is I believe, a very primitive method of taking up play in the main spindle sleeve. I had a go at nipping it up to try and get rid of a slight wobble in the spindle box but it very quickly locked up the whole head assy! As I said, very primitive.

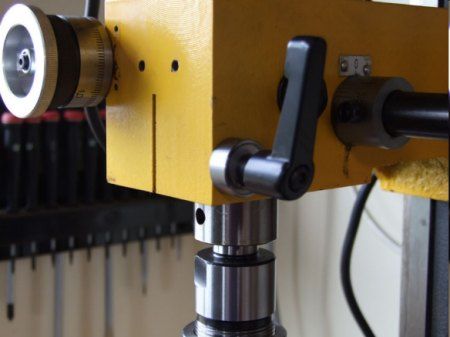

I believe number 2 is supposed to be the quill lock but again, it's another very primitive effort that would benefit from a lever or handle so searching for the mod that Frances refers to might be worth a go. To date though, I haven't found a need for it.

Hope this helps a bit

Iain

Michael Gilligan.

Michael Gilligan.