I think you need to look into the issue of the digital phase converter very carefully. You will lose lots of functionality with a DFC connected directly to the motor. One of the key lathe functions is the "instant" 4 times speed reverse when threading. This makes threading without disengaging the half nuts a piece of cake. For this to work you need the electric clutches and brake to be working together with the electric switching. I think you should consider a rotary phase converter as your base case.

I've just had a thought that if your machine is for the UK market maybe it's imperial and you have a threading dial. Some photos would be interesting to see.

I am very pleased with mine. I have zero experience with machines of this quality but it is all I expected and some. It's extremely rigid and precise. I attempted to test the brochure claim that it is impossible to get it to chatter. I tried the maximum DOC (16mm) in mild steel that my carbide cutter would allow. It passed the test like I was taking a finishing cut. Also when you dial in a DOC that's what comes off every time, no more no less.

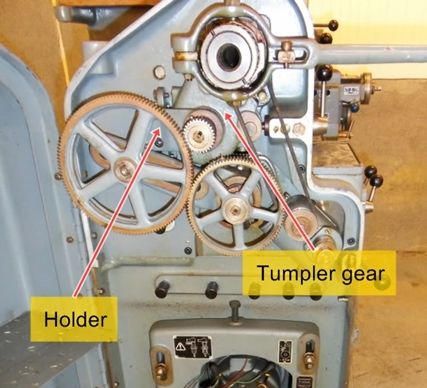

I'm not sure what you mean by reverse gear. I did have some noise issues with the 4 times speed reduction gear (when in reverse) but that was largely me being over sensitive. I've given up trying to eliminate it (for the moment).

The spindle oilers are a pain to set to the right rate as there is no feedback on the actual "drip rate".

The as supplied QCTP is limited in functionality as the bottom edge of the tool holders sit lower than the top face of the top-slide. This prevents rotating the tool post to achieve the desired angle. This means you need lots of extra tool holders, which of course are none existent. I replaced the whole thing with a Multifix type A. Because of the relatively high height of the top of the cross-slide the Multifix is limited to 12mm square cutting tools if you want to retain the 40 position capabiity. You can of course mount 20mm square cutters directly on the cross-slide when more umpf is needed.

I also fitted a 2 axis Newall DRO.

Phil

Mike Blankley.

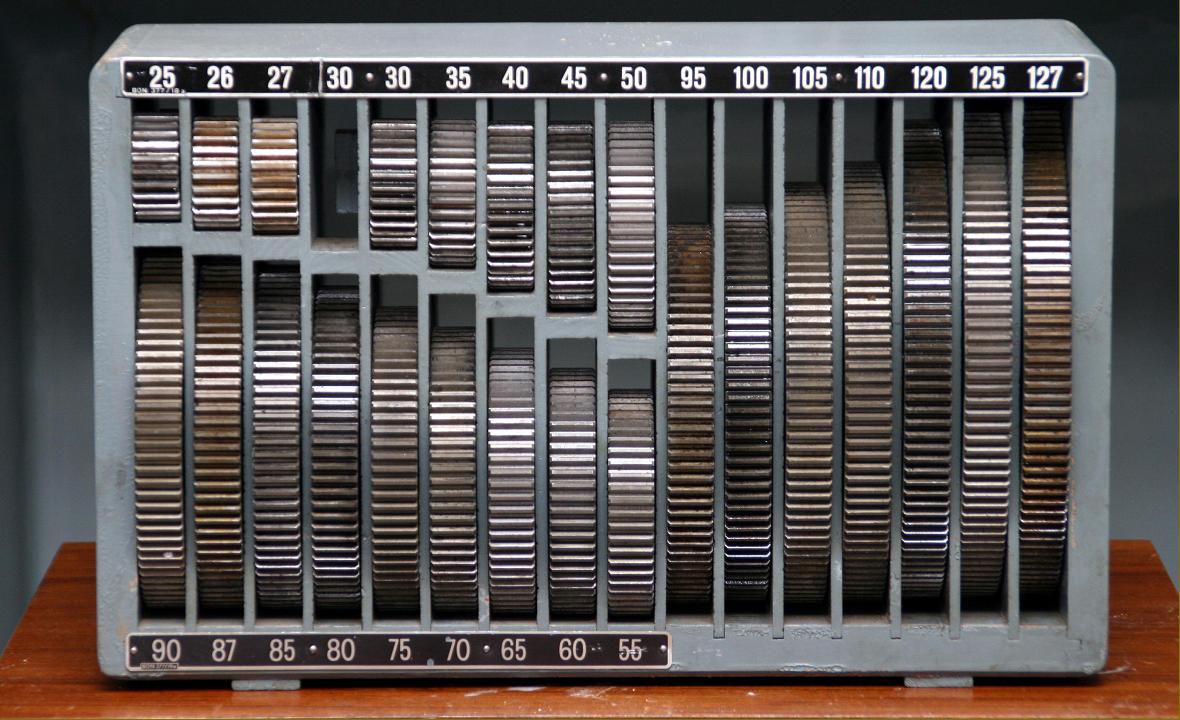

I am very interested in any plans or info regarding the construction of it, I am guessing it consists of three gears? Gear connected to output shaft on center of rotation? Gears are the same module as change gears I assume?

I am very interested in any plans or info regarding the construction of it, I am guessing it consists of three gears? Gear connected to output shaft on center of rotation? Gears are the same module as change gears I assume?