Hello

I need to make about 32 identical, small pieces of rectangular mild steel plate with dimensions: c.16 x 13 x 1mm.

The tricky bit is that I need to put a chamfer on one edge of the steel that is EXACTLY 45°.

Background

It is just for a novel product idea that I am working on.

I am thinking that in principle I just just cut a long strip of steel that is 13.1mm wide, and put a 45° chamfer on it and then cut it up into 16mm lengths.

My first problem would be cutting a long strip of steel by hand (using a hacksaw) reasonably accurately, before I file it flat.

But even more difficult would be putting an ACCURATE 45° chamfer onto one edge. With enough time and very careful filing and sanding I suppose this is would be possible, but not easy!

So was thinking that maybe I should buy a small desktop milling machine.

Any suggestions?

With thanks

J

PS FWIW, I do own a small Proxxon drill, with a small Proxxon Micromot 50/E rotary drill with possibly I could use a small grinding wheel. However although it seems very well made, and spins at up to 20,000 RPM, it's only 40watts. And in any case I fear that there might a bit of chatter, no?

So do you think I should add to what I have got…?

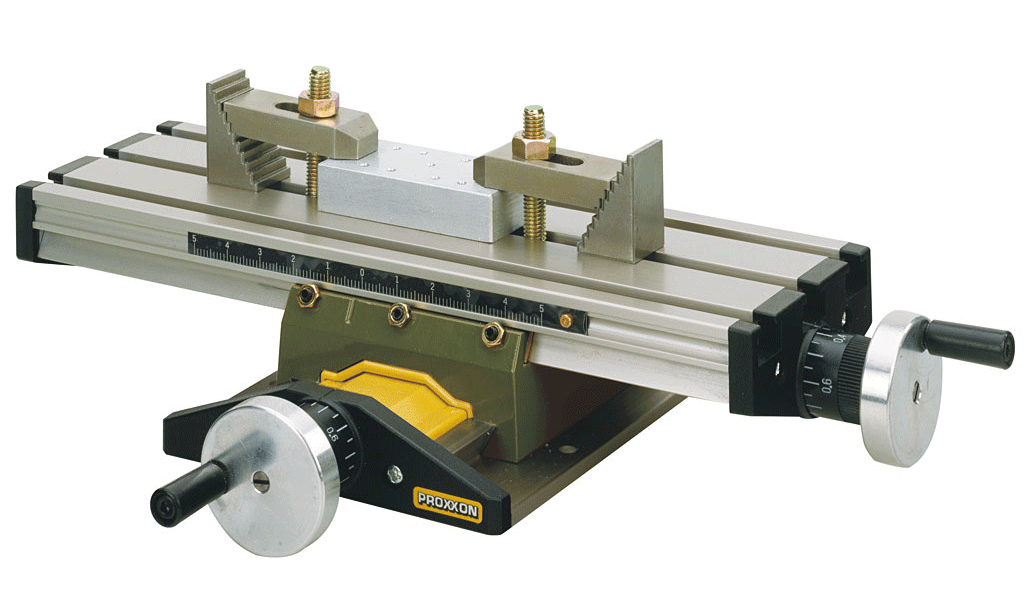

e.g. Possibly I could add a Proxxon "MICRO compound table KT 70"

https://www.proxxon.com/en/micromot/27100.php

Possibly with some sort of vice(??)

However according to this youtube video this table suffers quite badly from wobble !

https://www.youtube.com/watch?v=Ws6UwE1qB2I

OR should I just start again from scratch and buy a different system?

NOTE: I have never used a milling machine before, so although I am keen to buy something that is well made with good quality, I am needing to be cautious. Also I just have a very small home workshop so whatever I buy needs to be pretty compact!

Any advice?

J

JasonB.

JasonB.

adjusted regularly to present an unworn part of the wheel to the workpiece. Hopefully, one grinding wheel may last long enough to do all 32. If unsure, lay in a store of wheels.

adjusted regularly to present an unworn part of the wheel to the workpiece. Hopefully, one grinding wheel may last long enough to do all 32. If unsure, lay in a store of wheels.