ADVICE, Aftermath of a Lathe Bed regrind.

ADVICE, Aftermath of a Lathe Bed regrind.

Home › Forums › Help and Assistance! (Offered or Wanted) › ADVICE, Aftermath of a Lathe Bed regrind.

- This topic has 25 replies, 9 voices, and was last updated 25 August 2016 at 23:45 by

Russ B.

-

AuthorPosts

-

19 May 2016 at 13:07 #239316

Russ B

Participant@russbThis is a very, very open post/question, I welcome any comments, shared experiences, advice, warnings, anything, This is new ground for me and I'm not sure what to expect.

I've received a quote to have my lathe bed reground (a Myford 280). The bed wear on the front vee is visible to the naked eye with a lip on top. I love the lathe, everything else is in fine fettle although I will be rechecking a few things when it comes to stripping it down to send the bed and saddle castings off.

The regrind includes flats, angles and underlip on the bed, plus a record of home much was removed. It also includes regrinding the flats and angle of the saddle followed by application of Turcite B followed by regrinding again but allowing for the material removed from the bed so the leadscrew/gearbox will realign.

I was intending on leaving the headstock and tailstock as they are. I will check the fit of the headstock onto the vees and flats and panic as required if/when I discover the fit is not exactly the same? (Is this silly?)

I don't know what to expect, will the spindle bolt back down nicely or will it need scraping in – would it benefit from scraping in anyway (I like scraping, but some things are just best left alone/to the professionals!)

Overall, I'm really looking forward to it but I'm a bit unsure what to expect when it comes to bolting it all back together.

19 May 2016 at 13:07 #32700Russ B

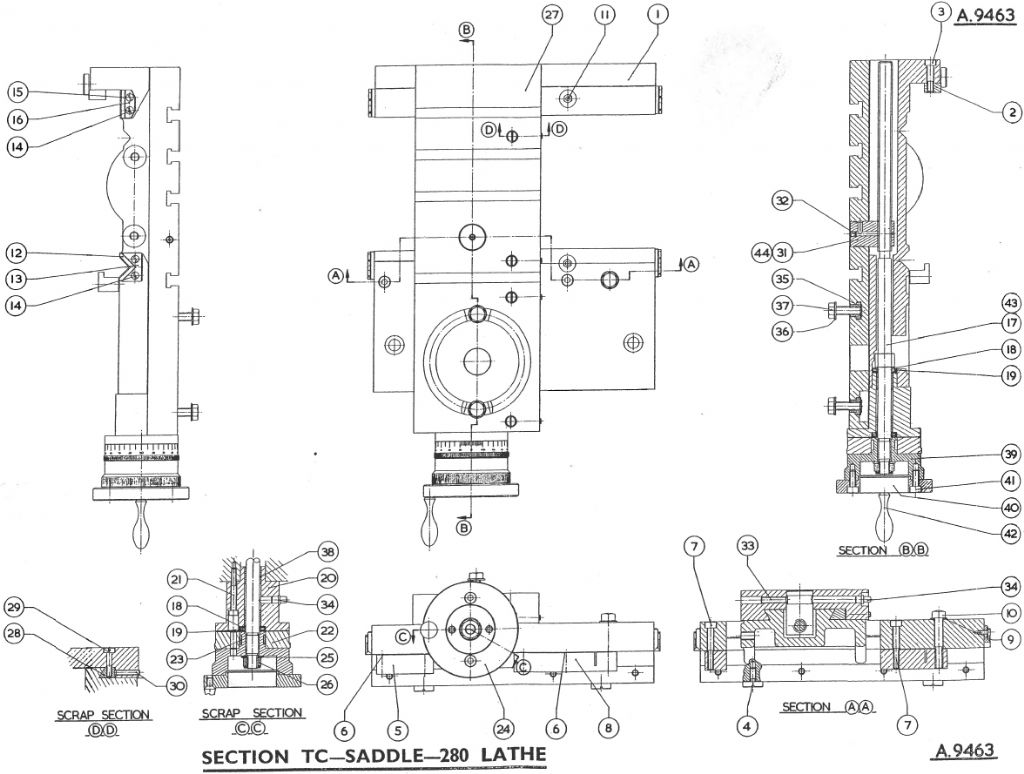

Participant@russbMyford 280 regrind.

19 May 2016 at 13:32 #239319 BazyleParticipant@bazyle

BazyleParticipant@bazyleNo experience but if the headstock mounts on the bed that has been ground down then it will be lower. The tailstock will be lower by the same amount assuming they ground the second set of ways the same. However it is likely the tailstock ways are less worn but the the tailstock base is worn so it would end up low. If possible get them to minimise the tailstock way grind so the tailstock base can be skimmed to make it match the headstock.

If the saddle is ground and scraped to the bed without the turcite it will be a few thou lower but that doesn't matter. I see no point in the turcite which is intended to obviate the extra expense of grind and scrape, and to relevel the top of the topslide if worn assymetrically. That is only necessary if you use it as a boring table.

19 May 2016 at 15:07 #239328Peter Krogh

Participant@peterkrogh76576I don't know the geometry of the Myford very well. That said I would suggest talking over the job with the rebuilder as he will have the necessary knowledge as to fitting the head stock and tail stock. Most lathes do require some fitting there to achieve best alignment.

Pete

19 May 2016 at 15:10 #239329Russ B

Participant@russbBazyle thanks, they have assured me they will be grinding the minimum possible off the bed. I did think about the tailstock and if needed, I will (attempt) to make a new base from scratch and hand scrape it to fit. (attempt being the key word here)

I need to make a fixed steady so I will get a bit of practice in on something less important first.

Below is a photo of the wear on the front of the vee, as you can see from the lip on top it's pretty significant thus I doubt just a few thou will do the job. The lip is so big I originally thought it was supposed to be there till I noticed the tailstock end has nothing!

The quote has jumped from a little over £600, to a little under £900 (as he thought it was a different machine) Considering the only other Myfords all have flat way beds, the increase in price is very small when taking in to account the additional work required to grind the 4 vee faces on the bed and apply and grind turcite to an additional 4 faces on the saddle – he's going to be a busy boy!

Still, I think I will then have a nice metric machine that will last me a lifetime with ample TLC and im only 29!!!

Peter,

You just replied as I was writing this. I have spoke to him and he said he will take care of it, but that doesn't mean anything if you ask me and that has made me think, I'm going to have to do a bit of scraping. I find this daunting but I'm very good with metrology so I'll just take my time – measure thrice, scape once – measure thrice again!

Edited By Russ B on 19/05/2016 15:15:47

19 May 2016 at 16:19 #239339Ajohnw

Participant@ajohnw51620I'm not familiar with this lathe but if the bed is reground the general dimensions should be maintained. Just moved down a touch is a another way of putting it so the rails become a touch thinner. It looks like the head and tailstock are located on the same V and flat so nothing will change in terms of how these fit. Both the V and the flats have to be ground to achieve this. The saddle is also probably located on the other V and flat so nothing changes there either. If the bed is worn the saddle is bound to be.

Some slideway grinders have a sub table at the end. This carries the saddle and can be used to ensure that the V in it and the flat correctly match the bed. One thing I would mention to them is that you do want to be able to face near square to the original specification. That will be very very slightly concave. I've had to mention that when I have had a cross slide reground. It takes very careful setting up. I'm not sure how well this works out when the underside of the saddle is being ground as well.

My father had lots of machines reconditioned – big advantage as he put lots of that sort of work out. In order to minimise the amount of material removed from the bed he told them to stand the bed upside down on parallels directly under the feet and take their 0.030 off the feet. Then put the feet where the parallels where, clock up the bed and regrind it. He'd even mic up the bed so he could check how much had been removed. If more than he thought it should be – no payment. I don't think many just take that sort of amount off a bed now but packing under the saddle probable does help them with setting up.

John

–

19 May 2016 at 17:48 #239352bricky

Participant@brickyI have a Myford S7 mark 1,I had this reground at Myford 2005 and have never regretted it.It is so accurate I prefer it to the S7 large bore for the odd jobs that require precision.I would certainly have it done.

Frank

20 May 2016 at 10:00 #239448John McNamara

Participant@johnmcnamara74883Turcite? an alternative is Moglice **LINK**

The turcite I know of is glued on in strips, it then has to be scraped down to fit. Moglice is an Epoxy composite that is spread on then you use the bed as a pattern.

I used this method for my lathe. it has run on Epoxy bedding material since 2010 **LINK**

For one job it would probably be less expensive to buy Moglice.

The tailstock on my lathe was also worn, I was able to grind 2 exact shims to pack the front and rear back into line. the shim was placed under the top section where it meets the base (the joint used to set over the tailstock)

On my lathe the headstock is located by an extension of the actual ways, so there was no alignment problem there, it simply bolted back on….. Ok with a tiny bit of scraping.

That covers aligning the headstock, tailstock and bed.The saddle is a more interesting project. It must be set in exactly the same position as it was when the lathe was new and not worn, otherwise the driving rack and pinion, leadscrew, and control bar if the lathe has one will be out of line.

The geometry of the cross slide must be set back to tool room specification.

The method I used was to make 4 jacks….. a piece of 12mm plate with a 45 deg V in it and jack screws with lock nuts facing into the V. Each plate was bolted to the saddle using the wiper screw holes. You may have to drill your own if they are not in the right position on your lathe.

Using the jacks I was able to suspend the saddle above the bed adjusting and measuring until it was perfectly positioned in every plane. it was then lifted off and the bearing material was applied to the underside of the saddle.

Before doing this the bed was very carefully masked off exposing only the V ways the ways were given a coat of release applied very carefully….. Epoxy sticks very well.

It was than a simple matter to replace the saddle this forces the epoxy to conform to the bed and once set overnight you are almost done. There will be excess Epoxy to carefully remove. and the top of the V groves filed out carefully so the the saddle only rides on the V's

There is a minimum thickness requirement for epoxy you may have to grind or mill a little off the saddle V's

The process worked really well for me the tired old lathe was transformed.

This is not a process to be undertaken by anyone that does not have the skills to do it. it requires (very) accurate measurement and an understanding of the underlying principals that define a lathe.

Regards

John20 May 2016 at 11:46 #239458Russ B

Participant@russbJohn, you deserve a medal for that explanation – It's like I was with you in the room!

My bed ways extend end to end and the headstock simply sits on the vees and maybe it touches the flats but I haven't stripped it down yet. I have been leaving the stripping job till last in a (vain) attempt to ensure I can machine/scrape any templates/standards/jigs I need before I start – its almost like I actually believe things will go according to a plan!!!

The process of machining the jacking plates and fitting them to the saddle sounds very very much like the easy part. This Moglice certainly opens doors and given my limited budget, and limited confidence in "as ground" fits – this is right up my street.

I think the cross slide will need quite a bit of scraping in anyway. It is visibly worn. I think it would be unwise to take reference from the cross slide dove tails or the bearing vee's underneath.

Edited By Russ B on 20/05/2016 11:58:10

20 May 2016 at 12:56 #239461John McNamara

Participant@johnmcnamara74883Hi Russ

The cross slide will have to be done first because it generates a line at 90 Degrees to the spindle axis. When setting up the saddle to the bed the cross slide must work perfectly, that defined line is used to set the cross slide to face a work piece flat or a tenth or so dished over 300mm . The cross slide is almost certain to be worn at the point where most average tools hit the average bar turned. Somewhere towards the middle of its travel. Try to keep the original 90 degree geometry, take a little of each side. Remember the apron and lead screw must remain parallel to the bed.

By adjusting the gib's to a good fit in that so called normal average position you are almost certain to find it binds at the extreme in and out position. Any binding indicates wear. I would disassemble clean and reassemble before performing this test in case a bit of swarf is the culprit.

It is important the slide and dovetails are scraped so that the slide describes a perfectly straight line from end to end. Use a known straight edge and a dial indicator mounted on the slide to test for this.

The contractors you are in discussion with have indicated that they will use Turcite and grind it in. I guess the real question is how accurately will they align the saddle? setting it up against the spindle axis. Will they do it to the Lathes original specification?

As an aside the head on my lathe also sits on the v's however the fitter who assembled the lathe when new had done a little scraping to tweak the fit against the v's I found it when I disassembled it. The as ground set up was not quite to spec. One would hope your contractor would do the same.

Dr Schlesingers classic book I believe out of copyright he passed away over 50 years ago should be found here:

About Him and Myford!

http://www.practicalmachinist.com/vb/redirect-to/?redirect=http%3A%2F%2Fallanjbester.co.za%2Fpersonal%2Fmachining%2Fdoc%2FNo%2520Limits_Georg%2520Schlesinger.pdfI hope you find it useful

Regards

JohnEdited By John McNamara on 20/05/2016 13:16:05

20 May 2016 at 14:02 #239466Russ B

Participant@russbJohn,

Thank you I will look at the book very soon, as it's far more condensed than the texts I currently follow!

I will also digest your post in full soon once I have time to get my concentrating cap on (real work keeps getting in the way of the fun stuff!)

My current "bible" is 530 pages of "Machine Tool Reconditioning & Applications of Hand Scraping" by Edward F Connelly (1954) – the copyright was renewed in 1982 exactly the year before it would have been in public hands. The renewal gave it another 47 years, and a bill passed in 1998 adds 20 to that, thus we can't have it freely until 2049 at which point I will be about 63, hopefully still alive and thus retired and will no doubt print and preach it to anyone daft enough to listen! The latest print was 1992 I think (eighteenth) It does say it is a reprint of the original but it has been retyped in a clear font and with any luck, the images might be clearer (the diagrams are still clear on the early editions but some of the images are dark)

Many thanks,

Russ

20 May 2016 at 14:20 #239471Hopper

Participant@hopperHave you contacted the Myford company about getting your regrind job done? They would be more familiar with the machine. I can't see the value in paying 900 squids to get the bed reground then turciting or moglicing the carriage, cross slide etc. Properly done metal to metal is going to give you the closest to "as new".

20 May 2016 at 14:35 #239474Hopper

Participant@hopperPosted by Russ B on 20/05/2016 11:46:22:……I think the cross slide will need quite a bit of scraping in anyway. It is visibly worn. I think it would be unwise to take reference from the cross slide dove tails or the bearing vee's underneath. …

A common way of doing it is to use the unworn side of the crosslide dovetail that is covered by the gib strip (the one where the gib screws are drilled and tapped through it) as first reference. The opposite side of the dovetail is scraped parallel to this using rollers and a mike to measure the distance, and a prismatic straight edge (you do have one of those ?) to get is flat, straight and to the correct angle. The mating fixed dovetail surface is then scraped to match this surface. Then the other side of the fixed dovetail is scraped parallel to this using roller and mike and prismatic straight edge.

Then, the V ways in the bottom of the carriage have to be scraped to match the newly ground bed. It is here that the setting of the angle of the cross slide ways relative to the lathe's main axis is set. So you are scraping to mate the four surfaces of the V ways, and to sit the carriage level in the x axis, and to set the carriage level in the Y axis, and to set the cross slide to turn half to one though concave over the radius of the faceplate. Plus, it all has to be done without removing more metal than the halfnut adjustment can accommodate to maintain leadscrew alignment.

No mean feat. Probably not the ideal place to learn to scrape. You might want to try making yourself a surface plate, couple of camel back straight edges and a prismatic straight edge first, just to get your scraping skills up to scratch.

BTW, I have read that there is also a business out there run by two former fitters from the Myford works who do reconditioning work. Not sure who they are or their business name but I am sure others on here will know. They may be helpful to you?

PS, these guys may be of help to you too.

http://www.lathespares.co.uk/myford-machining-grinding-servicing

Their prices for cross slide and saddle regrinding seem pretty reaonalbe, although their quotes are for ML7 etc and not your 280. Still, at that price it probably is not worth getting into the whole scraping thing.

Edited By Hopper on 20/05/2016 14:44:28

Edited By Hopper on 20/05/2016 14:44:59

Edited By Hopper on 20/05/2016 14:56:34

20 May 2016 at 14:54 #239475Russ B

Participant@russbI have contacted them, the Myford 280 might as well have been made by aliens and beamed down from space because no information or history seems to exists -it's as if all things Myford 280 related was locked in a box and thrown in the ocean to make way for the smaller, simpler and cheaper to produce 254's which caught the markets attention.

"up to scratch"

I like it.20 May 2016 at 15:00 #239476

I like it.20 May 2016 at 15:00 #239476Hopper

Participant@hopperPosted by Russ B on 20/05/2016 14:54:24:I have contacted them, the Myford 280 might as well have been made by aliens and beamed down from space because no information or history seems to exists -it's as if all things Myford 280 related was locked in a box and thrown in the ocean to make way for the smaller, simpler and cheaper to produce 254's which caught the markets attention.

"up to scratch"

I like it.

I like it.LOLz, Yes, sounds like my scraping altogether.

See the PS I just added re lathespares.co.uk above. Unless they decline to touch the alien lathe too?

If your contractor fellow can do the cross slide and saddle regrinding for similar prices maybe be you should trust him to do the job. (properly, not turciting about etc) Main catch would be that there is some means of moving the halfnuts etc upwards by the amount that is taken off the lathe bed and the saddle ways so the nut lines up with the leadscrew still. And even if the regrinder did mess up and not get the cross slide turning the needed half thou concave, a relatively small amount of scraping of the saddle V ways would fix that. Much easier than scraping the whole job.

Edited By Hopper on 20/05/2016 15:05:20

20 May 2016 at 15:00 #239477Russ B

Participant@russbIt must be noted that the bed is NOT a flat way bed and thus not like any other Myford ever produced. It could perhaps be more familiar in the hands of an experienced Harrison or Boxford fitter.

20 May 2016 at 15:11 #239478Hopper

Participant@hopperAny machine tool fitter worth his salt should not have a problem with V ways. Other than Myford, they are pretty much an industry standard these days. Same with the regrinding. It is just a matter of using the same grinding machine but with different wheel set up. (Providing their grinder is not some stone-age relic ) Just costs more because you have a bit more set up time and fiddling about for the V ways. which probably has a lot to do with why Myford used flat ways in the first place.

20 May 2016 at 15:33 #239479Russ B

Participant@russbI much prefer flat ways. The Myford 280's Vee shears are completely removable from the bed casting – I could convert it to precision ground flat ways and take care of the whole scrape job.

I'd just need a new saddle (simple enough we're talking flat ways) and a precise adaptor for the headstock * tailstock – I might as well bump the centre height up to 150mm while I'm there!

However I think I'd better not chop up a piece of nearly lost Myford heritage!

20 May 2016 at 17:19 #239489Ex contributor

Participant@mgnbukThe turcite I know of is glued on in strips, it then has to be scraped down to fit. Moglice is an Epoxy composite that is spread on then you use the bed as a pattern. For one job it would probably be less expensive to buy Moglice

I have had the misfortune to come into contact with Moglice in the past, both on fresh installations on new build machines & during rebuilds. Compared to Turcite it is a most unfriendly material to work with, being very abrasive to scrape (the MTB I worked for who designed a vertical milling machine around injecting the stuff always ended up scraping it – mainly to match in the patched blow holes & bits that came away stuck to the release compound). The main problem with it is it's lack of long-term adhesion to the parent metal – I have come across this on mass produced machines (Deckel milling machine – possibly injected) & short run machines (Crawford Swift lathe – trowel applied), where it looked on first inspection to be in good condition, but a bit of tapping with a blunt instrument (file handle) showed large areas that were no longer bonded. Where it is attached properly you get a nice "ting" sound, like tapping directly onto the parent casting, where it is loose it gives a dull "thock" – the loosening appeared to start near the oil holes & radiated outwards as the oil got between the Moglice & the casting (something that doesn't seem to happen with Turcite).

I have seen this stuff stripped off a casting with a wall paper stripper – which is probably why most MTBs use Turcite or a similar tape glued on & not Moglice. This not to say that Turcite (or simliar) tapes cannot come adrift but such occurrences were rare and, given that this is the predominant system, as a percentage of installations quite low. Whereas pretty well 100% of Moglice (or similar) installations I came into contact with had some kind of problem – either during installation or during refurbishment. This could be initial adherence, where the stuff would steadfastly refuse to stick to thoroughly degreased, rough planed surfaces, but would stick tenaciously to the carefully applied release agent on the ground way. Or coming loose in service, as described above. Or, on the one occasion I can recall where the Moglice was still servicable during a rebuild, the abrasive nature of the cured material caused a lot of problems – we ended up buying two boxes of Sandvik carbide scraper inserts (20 inserts). One pass over the face blunted the scraper edge, 4 edges per blade – we usually had one box of inserts away to be diamond lapped while the fitter worked through the other box, with a box going to & from the grinder every couple of days for nigh on a fortnight ! In hindsight it would probably have been cheaper to have stripped the Moglice off & replaced it with a tape system, where 1 scraper insert would have completed the job.

IIRC the minium working thickness for Turcite is 0.5mm, so by the time the bed & saddle have been cleaned up, chances are that little extra will have to be machined off the saddle to get the Turcite in.. It is easy to machine and to scrape, works well with marginal lubrication (IIRC Moglice doesn't) wears well & is kind to the slides. It can also absorb debris to a limited extent (Moglice scores). Given a choice, I would choose Turcite, Guidecoat or Rulon (the latter two used by my previous employer) in preference to Moglice – TBH I would probably prefer metal to metal to Moglice ! As the Turcite strip can be bought in different widths & thicknesses, the cost is not likely to be major part of the overall quote. IIRC the glue could cost almost as much as the tape for smaller jobs when I had to order it, though a specialist would most likely have part-used tins to hand.

(properly, not turciting about etc) Adding Turcite is an enhancement, not a "bodge" as implied here ! That it should return the apron mounting face to close to it's original position relative to the bed is making life a lot easier at rebuild time.

I am a bit suprised that the contractor you have approached is not regrinding the cross slide & ways as well as the saddle & bed – the guys I used to use would have done. Ask him to grind the tops of the "vees" at the same time if he had not intended to to do so – somewhere to sit the level without having to use parallels off the flats & that will not wear in operation for subsequent checks.

I doubt that your headstock will need much work, but you will need a test bar to check the alignment when you come to rebuild the machine. I would also strongly suggest buying or borrowing a precision level & not relying upon the much quoted "Rollie's Dad's Method" (whoever Rollie's Dad was).

Not intending any antagonism towards John McN here – just that my industrial experience of Moglice & the like has been uniformally negative.

Nigel B

20 May 2016 at 18:59 #239497SteveI

Participant@steveiRuss,

I am very much a beginner to machine rebuild. So take that in to consideration if you read my post further.

There has been a lot of interesting replies to this post. You have not indicated your level of experience with lathe rebuilding. Are you an accomplished rebuilder? Scraper? Perhaps the advice could better target your competency if you let us know.

If this is your first time and you do not intend to rebuild another machine then I would suggest to consider taking the professional up on their quote. If you are determined to rebuild it yourself then if you consider this lathe to be a “keeper” then I would respectfully suggest buying something else to practice on and make all the mistakes on. For example something with lots of cheap replacement castings in case you make a mess of it. Then you will stand a much better chance of doing a rebuild that brings the 280 back to factory tolerance or better. Furthermore especially given your age you want to rebuild it so it wears in before it wears out. Finally the tooling needed to do a good job unless you are very lucky or plan to “rebuild the tooling” (scrape in your surface plates, straight edges etc as part of the journey will not come cheap. If this is your only lathe then some useful tooling you can make that will make the job easier and better, but needs a lathe to make!

Having said all that I have met people that have rebuilt machine tools (one of whom has done it professionally his whole life) and they all say if you can rebuild a lathe you can rebuild anything. I.e. it is not trivial to rebuild a lathe.

If you do decide to rebuild yourself you need to find your references and go from there. It is most likely every casting will have an original unworn machined area which was used in the original machining, grinding and/or scraping as a reference. Furthermore you can often find an area of the prismatic ways or a bearing surface that is unworn and then measure the amount of wear you have from that. In addition you can measure what you have taken off in the grinding or scraping. First job is to play detective and take notes. Don't grind or scrape anything until you know what you are dealing with. You can build a tool called a “kingway” (google it) to help you do that.

I am not sure some of the comments on turcite at the beginning are accurate. Regarding the use of turcite; you need the casting that is worn to be ground or scraped back square and you need to know how much has been taken off to use the most appropriate thickness of turcite (or adjust other dependent items to fit the new dimensions). You will need to fill with epoxy and then recut the oil channels for lubrication and scrape it. Turcite should not be used to obviate the need for grinding (to recover the geometry) or scraping (to recover the geometry and/or get the quality of bearing, it is going when glued to a geometrically square casting bearing surface to allow you to recover the original dimensions and have a "better" bearing. Turcite has low stick slip and can be much more easily scraped. It makes a nice smooth lathe into a super smooth delight. And when it wears out simply replace it knowing that the metal is still geometrically sound underneath it. Since you don't have a gap bed on this lathe type I would personally consider turcite if you are going to all this effort. I have an equivalent on the underside of the carriage on my new to me lathe that is almost finished rebuilt, in addition I plan to use it on the back of the knee and underside of the saddle of my bridgeport when I get to that stage in the rebuild. A metal on metal bearing may have been factory original but a modern design might have turcite from the factory. It is that good.

Finally if you do out source the job. Ask the rebuilder about their scraping and get pictures or see examples of their work. The bed should be ground as it is hardened. However what do they plan to do on the other castings bearing surfaces?

I have spoken with a few UK based rebuilders and the norm seems to be to scrape but only to "break up" the ground bearing to provide some oil pockets. E.g. this would be running up and down with a half moon BIAX. On the size of machines we are talking about you get 0.0002" over the whole way. The half moon scraping they do is simply to break up the bearing surfaces after grinding to avoid stick slip and galling. On your size lathe this would take a short time for a rebuilder with a Half moon BIAX. My bridgeport ways from the factory were ground and given the half moon treatment. Much much cheaper. Do you know what the Myford factory approach was?

The old fashioned top quality scraping to 20, or 40 Points per inch 50% bearing is not often done. (When I have asked about it some places I get a funny look; others that are more knowledgeable state it would be too expensive, time consuming and no one will pay for it. So if you want it will cost a fortune or you have to DIY!) This results in a much better quality bearing which the experts say should last longer. If you want that ask the rebuilder to just grind all the ways and send it back to you for scraping or have deep pockets.

Regards,

Steve

20 May 2016 at 19:01 #239498Ajohnw

Participant@ajohnw51620I don't know if you were in the room with this John or another John. However

Nigel

NigelAs far as I am aware the saddle side of the cross slide can be reground after the underside of the saddle has been done. It would also pay to have the actual cross slide done as well so that the angles match. It will also probably be worth while having the gib strip reground flat or fitting a new one.

Why as far as I am concerned – I have had that reground all on it's own. They matched the angle to a new cross slide which probably means that they ground that as well even though it was new. I did mention that I expected it to turn concave to myford's spec. Can't remember the numbers but it's dead square to turning slightly concave.

Why as far as I am concerned – I have had that reground all on it's own. They matched the angle to a new cross slide which probably means that they ground that as well even though it was new. I did mention that I expected it to turn concave to myford's spec. Can't remember the numbers but it's dead square to turning slightly concave.The subtable carries the saddle upside down with the V's in it offset from the bed V's. Then when ones side of the bed V is ground the opposite mating side of the V in the saddle can be ground at the same time. This ensures that the angles match.

It unusual to find lathes where the saddle rests on 2 V's. More often the rear V in the saddle that can be seen is clear of the bed and that side rests on the flat. I'm not saying it's never been done but getting V's to match up when there are 2 used like that is tricky to say the least – even a thou error would prevent them from mating correctly.

Scraping – forget it. Get all of the parts ground correctly. They need to match the manufacturers V angle closely os that the headstock and tailstock fit correctly.

On your bed wear just for interest the typical more recent lathe designs encourage that sort of thing because the guides on the saddle can't pass the head. Where they do the tool loads are applied more evenly along the guides rather than right at the end.

It annoys me because they are all well aware of that and it's probably why they all started hardening beds. Longer guides that do pass the head would last a lot lot longer.

It annoys me because they are all well aware of that and it's probably why they all started hardening beds. Longer guides that do pass the head would last a lot lot longer.John

–

20 May 2016 at 19:21 #239501Ex contributor

Participant@mgnbukIt unusual to find lathes where the saddle rests on 2 V's

The Southbend & clones / derivatives (Boxford, Denford etc.) use a "3 vee + flat" design, with the saddle running on the outer vees & the tailstock / headstock on the inner vee + flat.

On the pre-gearhead Boxford (and presumably the others) the whole "formation" was gang milled at one setup on a duplex head horizontal mill.

Nigel B

21 May 2016 at 02:47 #239549John McNamara

Participant@johnmcnamara74883The saddle resting on the two outer V's is optimal, with any type of slide way "crabbing" is the enemy, the load on the saddle is applied asymmetrically, tending to try to dislodge one corner of the saddle sideways and therefore up the V incline, Having two V ways reduces the chance of this happening. Most tool room quality lathes use this method.

Moglice dislodging ?

Unfortunately for this conversation I did not actually use Moglice I made my own Epoxy based material. It has given no trouble in the past 5 years since I did the rebuild. This is my only lathe and I use it to this day. When I applied it I cleaned, cleaned and re cleaned the 2 V's under the saddle I also used a small 5" disk sander to break the glaze and remove embedded grime. final cleaning was with solvent thinner. The V's were bright and a new paper towel was not marked by rubbing along the V.

Maybe the Moglice that gave trouble was applied in a less than optimal way?

It is clear Turcite or an Epoxy based material are both suitable contenders to do this work. I chose the Epoxy based method because I was able to perform the work myself. I do not own a slide way grinder. I did make a 150 kg grinding Jig but that is another story and the time input was huge, it would not fit on a small lathe.

If I was contracting the work out my main interest would be will the contractor be able to do the work and return the machine brought back to factory spec or better. Being a one off it should be better.

Regards

John21 May 2016 at 09:18 #239573Russ B

Participant@russbI'm just about to leave to go to the Doncaster model engineering show so I'll be brief.

The saddle sadly is not toolroom class, as can be seen from the detail drawings I posted earlier the wipers are positioned on the front vee and the small rear flat.

Regarding the saddle extending beyond the headstock, I agree, and this must be a cost saving excercise – it would also tends to shield the ways from a lot of fine swarf.

My scraping skills are ok but I'm very good at the manual aspects of spotting which is more important in my inexperienced opinion. I'm extremely sharp when it comes to deriving accuracy and generating standards from scratch. I was a civil engineering surveyor before I got (willingly) dragged in to mechanical R&D. I have an obsession with not relying on anything for accuracy. If you have me a surface plate I wouldn't believe it was flat till I'd tested it myself and only then I'd rely on it for a short time till it was retested. This is less of an attitude/approach and more of a disorder….

21 May 2016 at 09:58 #239580Ajohnw

Participant@ajohnw51620Posted by Nigel B on 20/05/2016 19:21:46:It unusual to find lathes where the saddle rests on 2 V's

The Southbend & clones / derivatives (Boxford, Denford etc.) use a "3 vee + flat" design, with the saddle running on the outer vees & the tailstock / headstock on the inner vee + flat.

On the pre-gearhead Boxford (and presumably the others) the whole "formation" was gang milled at one setup on a duplex head horizontal mill.

Nigel B

I must have been in cheap chinese lathe mode and thinking of various things I have seen. I have a boxford and yes the saddle does run on 2 V's. The 3rd V is added to align the head and locate the tailstock – less wear on that as it doesn't carry the saddle. The slideway grinder sub table can automatically take care of aligning the saddle V's with the bed.

I must have been in cheap chinese lathe mode and thinking of various things I have seen. I have a boxford and yes the saddle does run on 2 V's. The 3rd V is added to align the head and locate the tailstock – less wear on that as it doesn't carry the saddle. The slideway grinder sub table can automatically take care of aligning the saddle V's with the bed.I had a long chat with some one in Worcester some time ago who at the time had recently bought a brand new slide way grinder. I vaguely remember him saying that the tailstock can also be done at the same time but not sure about the head. The company seems to have disappeared.

The Boxford saddle slides do pass the head. All it means is that the head needs to neck in at the bottom or be narrower than the outer V's. One interesting aspect of that on a Boxford is that a lantern toolpost would place the cutting loads more central than a quick change. The travelling steady is designed to be used with a lantern tool post as well. It mounts on the tailstock side of the saddle and doesn't reach far enough for a quick change. Really they should have changed this sort of thing when they started supplying 4 way tool posts.

John

–

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Help and Assistance! (Offered or Wanted) › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Granville lathe leadscrew change wheel

1

2

Started by:

JACK SIDEBOTHAM in: Help and Assistance! (Offered or Wanted)

- 12

- 26

-

27 August 2025 at 10:21

cogdobbler

cogdobbler

-

Hereward

Started by:

Richard Simpson

in: Model Boats

Richard Simpson

in: Model Boats

- 5

- 10

-

27 August 2025 at 09:27

Richard Simpson

Richard Simpson

-

QCTP for chester lathe

1

2

Started by:

Chris12 in: Beginners questions

- 12

- 32

-

27 August 2025 at 08:17

Vic

Vic

-

Bending copper tube?

Started by:

Bo’sun in: Workshop Techniques

- 13

- 16

-

27 August 2025 at 02:05

cogdobbler

cogdobbler

-

Damp engine, Name?

Started by:

sivtek1 in: Stationary engines

- 5

- 10

-

27 August 2025 at 00:00

John Purdy

John Purdy

-

Softening epoxy

1

2

Started by:

John Haine in: General Questions

- 21

- 37

-

26 August 2025 at 22:32

duncan webster 1

-

The skill of the Victorian woodcut engraver

Started by:

vic newey

in: The Tea Room

vic newey

in: The Tea Room

- 5

- 6

-

26 August 2025 at 22:12

SillyOldDuffer

-

Smart & Brown Model L lathe help required

Started by:

AJAX in: Manual machine tools

- 4

- 11

-

26 August 2025 at 21:40

AJAX

-

Myford VMB mill, head lift.

Started by:

lctikka61 in: Manual machine tools

- 3

- 3

-

26 August 2025 at 20:41

Alan Wood 4

-

What Did You Do Today 2025

1

2

…

9

10

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 35

- 229

-

26 August 2025 at 19:59

Dalboy

-

Raab Style Heibluftmotor

Started by:

JasonB

in: Miscellaneous models

JasonB

in: Miscellaneous models

- 3

- 7

-

26 August 2025 at 18:53

JasonB

JasonB

-

3.5″ Derby 4F – First Loco Build

Started by:

mattleicester

in: Locomotives

mattleicester

in: Locomotives

- 5

- 5

-

26 August 2025 at 17:51

paul rushmer

-

Lathe tool inserts

Started by:

Andy Brocklehurst in: Beginners questions

- 7

- 13

-

26 August 2025 at 15:52

Andy Brocklehurst

-

Phone Phreaking

Started by:

Michael Gilligan

in: Clocks and Scientific Instruments

Michael Gilligan

in: Clocks and Scientific Instruments

- 12

- 16

-

26 August 2025 at 15:28

simondavies3

-

3″ Castings – Help/Advice needed

Started by:

Andy Porter 1 in: Traction engines

- 5

- 11

-

26 August 2025 at 12:37

parovoz

-

Valve gear problem

Started by:

John Billard 1 in: Locomotives

- 3

- 3

-

26 August 2025 at 09:08

Charles Lamont

-

Recommendations for book on clock repairs

Started by:

Andy Stopford in: Clocks and Scientific Instruments

- 8

- 10

-

25 August 2025 at 21:15

Andy Stopford

-

Drain Cock search

Started by:

Speedy Builder5 in: Locomotives

- 4

- 8

-

25 August 2025 at 16:48

Diogenes

-

Blackgates 3 Way Toolpost Casting

Started by:

John McCulla in: Materials

- 15

- 25

-

25 August 2025 at 16:06

Nicholas Farr

Nicholas Farr

-

Quartz clock movement

Started by:

duncan webster 1 in: Electronics in the Workshop

- 4

- 6

-

25 August 2025 at 10:24

Michael Gilligan

Michael Gilligan

-

Milling for beginners book, Where?

Started by:

andy198712 in: Beginners questions

- 8

- 15

-

25 August 2025 at 09:16

andy198712

-

Museum donation

Started by:

Stephen Wessel 1 in: Introduce Yourself – New members start here!

- 3

- 3

-

25 August 2025 at 06:54

Diogenes

-

THE MAUDSLAY TABELE ENGINE

Started by:

sivtek1 in: Stationary engines

- 4

- 7

-

24 August 2025 at 20:27

Michael Gilligan

Michael Gilligan

-

Progress no.1 restoration

Started by:

flyingsailor in: Workshop Tools and Tooling

- 9

- 12

-

24 August 2025 at 19:52

duncan webster 1

-

A4 stainless

Started by:

David Ambrose in: Materials

- 14

- 22

-

24 August 2025 at 19:15

old mart

-

Granville lathe leadscrew change wheel

1

2

-

Why as far as I am concerned – I have had that reground all on it's own. They matched the angle to a new cross slide which probably means that they ground that as well even though it was new. I did mention that I expected it to turn concave to myford's spec. Can't remember the numbers but it's dead square to turning slightly concave.

Why as far as I am concerned – I have had that reground all on it's own. They matched the angle to a new cross slide which probably means that they ground that as well even though it was new. I did mention that I expected it to turn concave to myford's spec. Can't remember the numbers but it's dead square to turning slightly concave.