Hi Michael, that's a very good question and I hope that I can answer it.

If you follow the link in my previous post it will take you to the LOCTITE Retaining Compound Design Guide. If you look at the bottom of page 14 you will find a paragraph on joint gap where it refers to the gap as being "diametrical". Also the chart on page 17 refers to "maximum gap fill diameter".

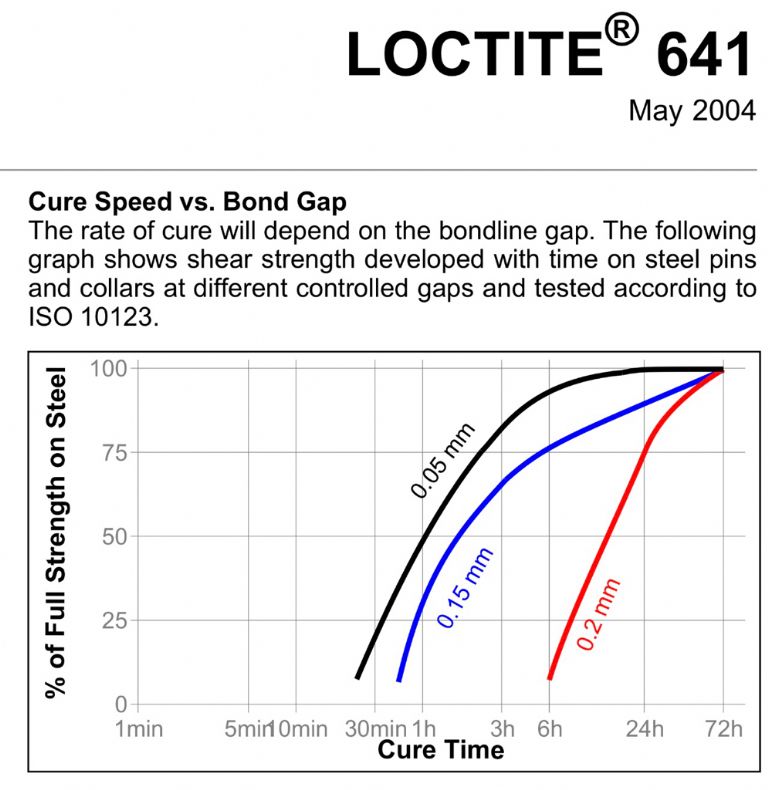

My personal view, and it is only my personal view, is that the graph on the data sheet for cure time against gap is misleading, unfortunately there is no graph for bond strength against gap, which would be more informative. Yes, LOCTITE will cure in large gaps, but its bond strength decreases with increased gap.

In my work and in my contacts with LOCTITE it has always been understood that the gap figures were diametrical as we were usually discussing the fitting of cylindrical components.

Of course, what we do in industry may not always applied in a home workshop. In industry "might be alright" is not an option, but at home, where you can monitor the success or otherwise of your work it is a different matter.

You will understand that the opinion I offer is from my own experiences in specifying LOCTITE in industrial applications. But, as my old boss would say, "design specifications are not tablets of stone". If you find that the larger gaps work for you, then go with it, there is probably some latitude in the LOCTITE specification, but not for industrial use where the product has to perform to the specification or you might be in trouble.

Well Michael, I hope that has explained my statement, sorry if I have rambled on too much.

Neil

Tim Stevens.