Forgive me if this is getting boring but I think there's a little more beginner interest to be squeezed from the question.

In my defence I deliberately cut a 70° bevel rather than the shallow 27° mentioned by Chris because I thought it would be easier to photograph. I ignored Chris's other dimensions as well – they didn't match the scrap in my junk box!

But people noticing the angle was 'wrong' allows me to comment on angling the tool-post as a problem.

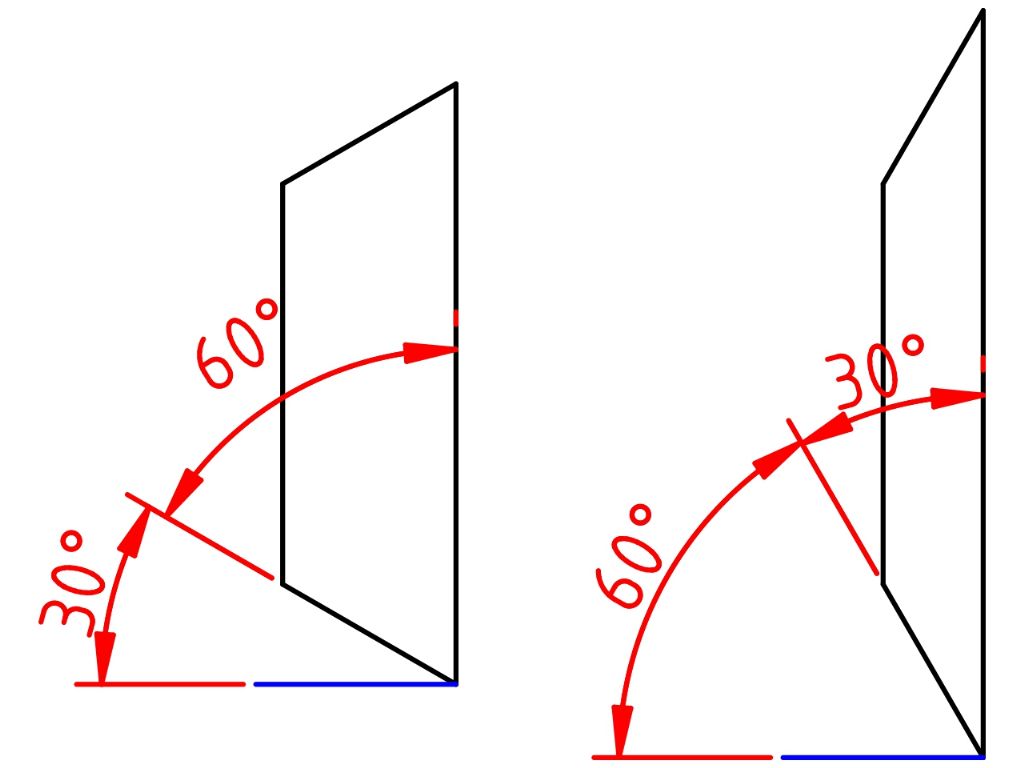

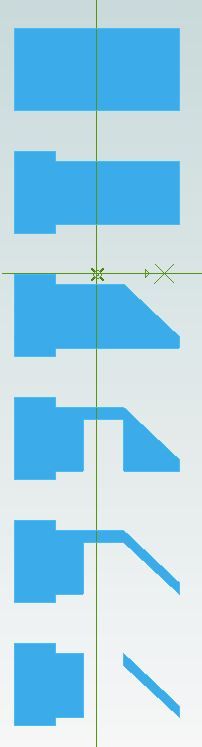

Not all lathes have an angle scale fitted. These have to be set either by gauge or by calculation, which might be necessary for accuracy anyway. On lathes fitted with with an angle scale the maker has a choice between showing either the post's angle to the saddle, or its complement ( 'opposite' ) which is the angle the tool cuts relative to the spindle axis. Getting it wrong makes a difference!

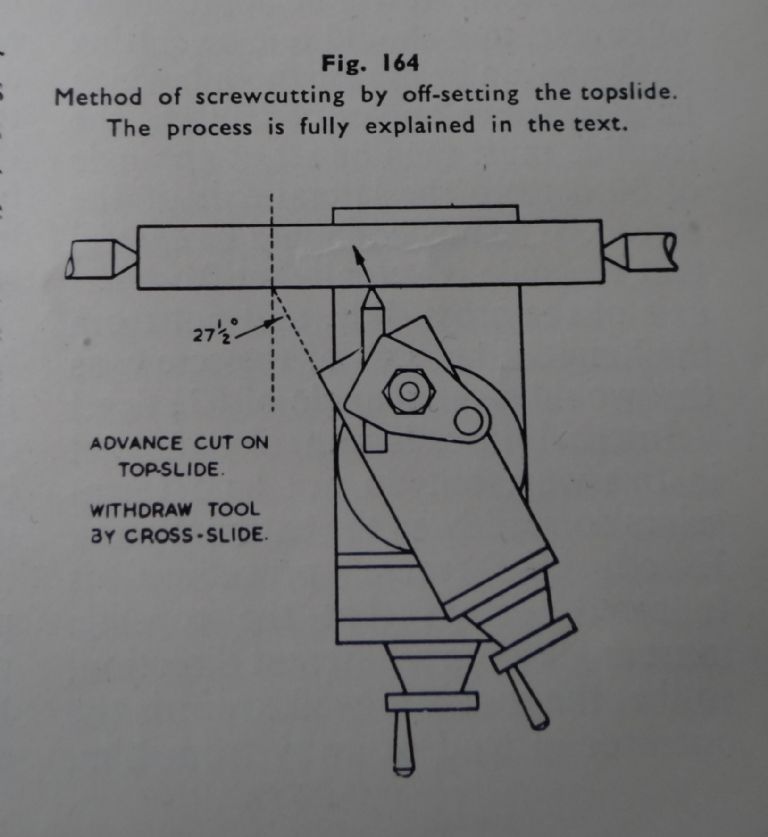

Quite a lot of beginners, including me, get caught when first attempting a screw-thread using the recommended set-over top-slide method as per the excellent Mr Sparey.

A small problem is that Sparey writing in 1948 recommends 27½° which is correct for 55° Whitworth but not ideal for a 60° metric thread where the offset should be 30° (ie half the thread angle).

However a much bigger problem is that – for Whitworth – the angle scale on my lathe should be set to 90°-27½° = 62½°, not to 27½° as specified by Sparey. Your scale may not align with Mr Sparey's instructions! Lesson learned: always check the angle at which the tool moves rather than assuming your lathe's angle scale has removed the need to engage brain!

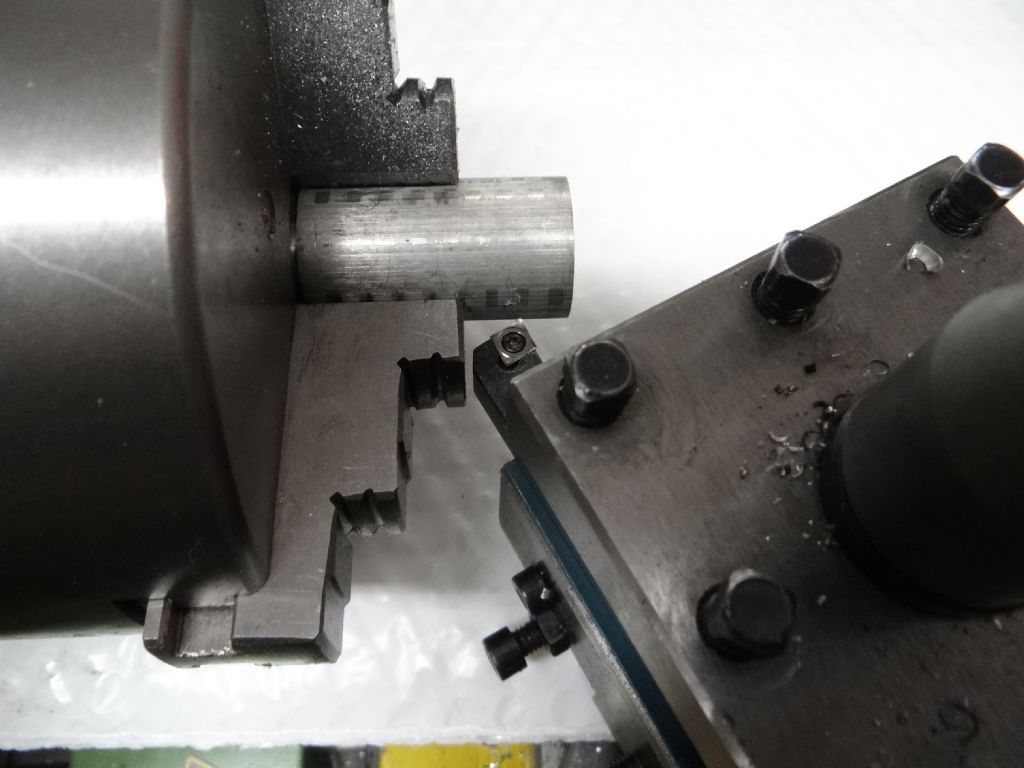

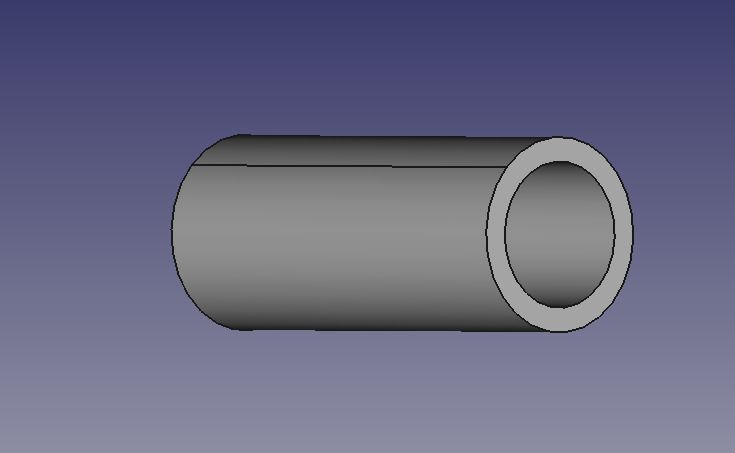

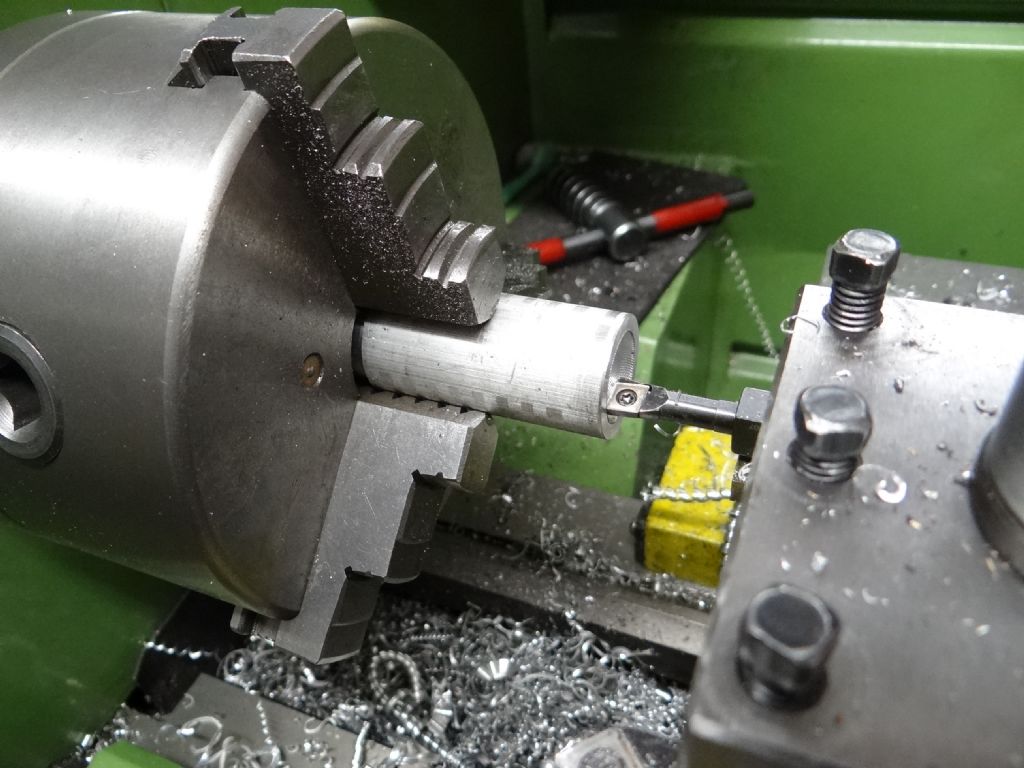

Michael pointed out that my demonstration is flawed by me cutting a deep bevel rather than what was in Chris' spec. Quite right, it is harder to to cut a shallow bevel because the tool gets in the way. In this photo the top-slide is at maximum travel!

I was able to get close enough by increasing the tool overhang. Normally I like the cutting point to be as close to the tool-post as possible. It reduces the risk of chatter. However, chatter wasn't a problem in this case even with a long overhang.

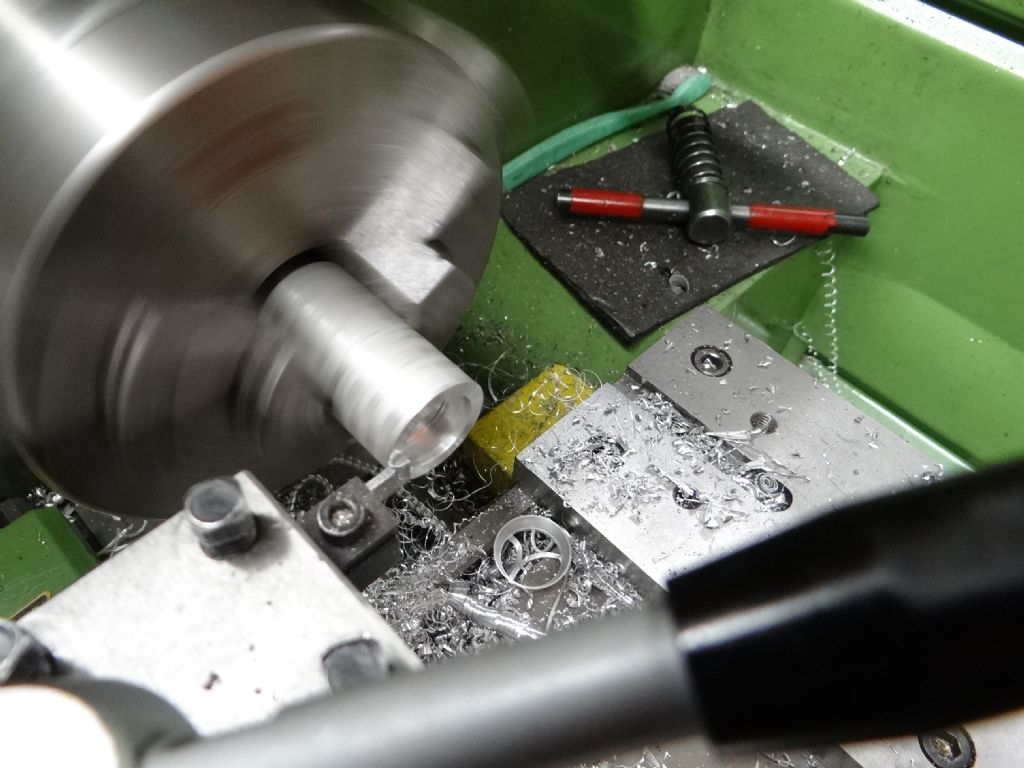

Another consequence of lack of space due to the angle was that Duncan's point about cutting a groove came into play! In order to make space for the insert holder, I had to rough-out a groove in the rod before making the real cut.

It's helpful when grooving like this that carbide inserts can cut along the full length of their exposed edges, not just at the point. Finish cuts in the second stage. There was no need to part-off with another tool – I just cut into the bore.

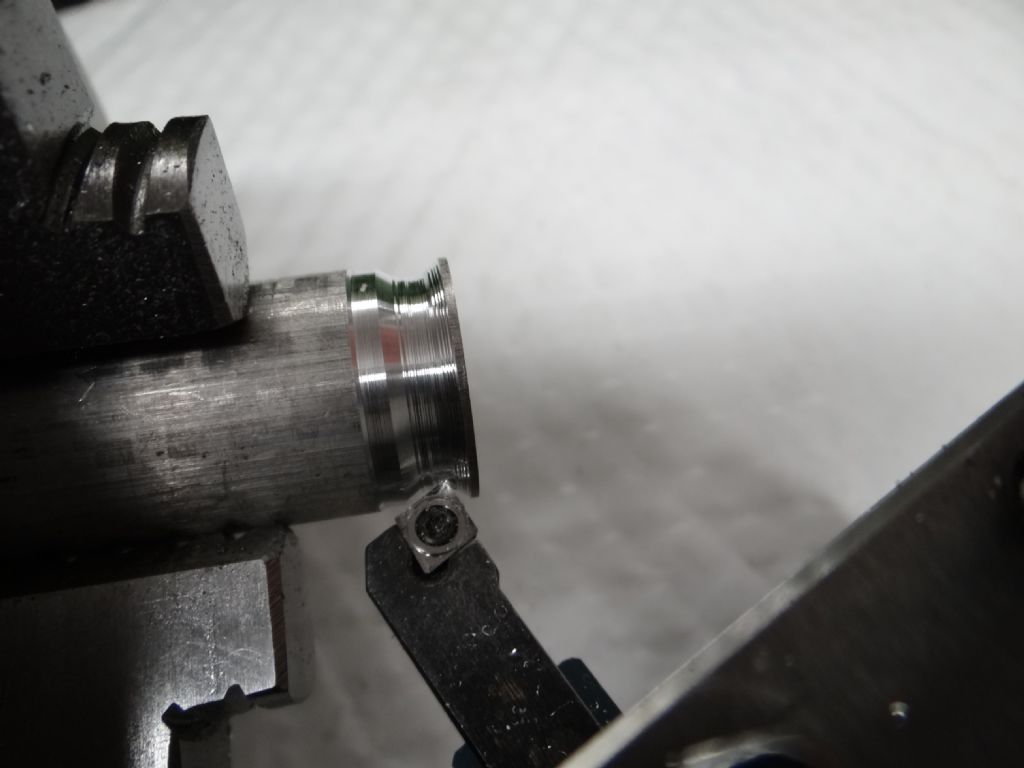

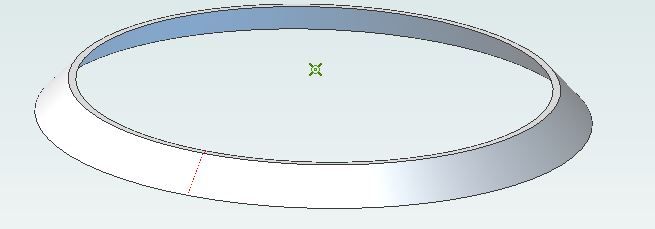

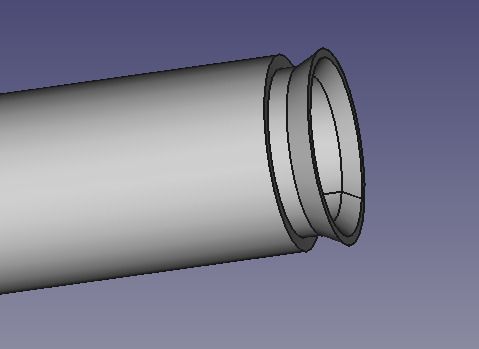

By the magic of Gimp, two photographs of the finished item merged for top and bottom views:

Other comments:

Cutting the inner bevel was easy enough but I did need to use a boring bar to get clearance. With a silver aluminium insert there was no repeat of the chatter I got with an ordinary gold insert.

At no time did I see signs of distress as the bevel got thinner.

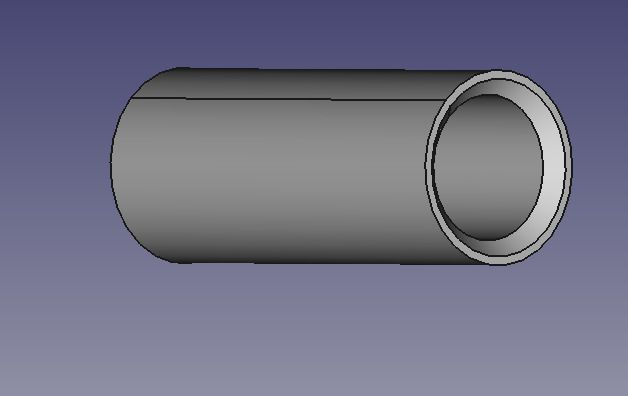

A disadvantage is the potential loss of accuracy due to having to position the tool with the Carriage Wheel. This has much coarser travel than the fine verniers on the top and cross-slides. Despite that I got to 0.63mm on a target of 0.6mm. It does make getting an accurate result slightly awkward though.

Thanks to Chris for providing a 'not too much work' diversion from domestic duties. I should be recycling junk and washing floors…

Dave

Edited By SillyOldDuffer on 05/02/2019 14:16:50

JasonB.

JasonB.

![20190204_172147[1].jpg 20190204_172147[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/823587.jpg)

![20190204_172229[1].jpg 20190204_172229[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/823588.jpg)

![20190204_172304[1].jpg 20190204_172304[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/823589.jpg)