Hi, i has Scotch boiler. Then i can tell you: With large diameter in flue tubes will have larger heat surface. With calloway pipe in furnace will improve the effect of boiler.

To example the boiler 100 mm diameter and 160 mm length and the boiler is fired with blow lamp:

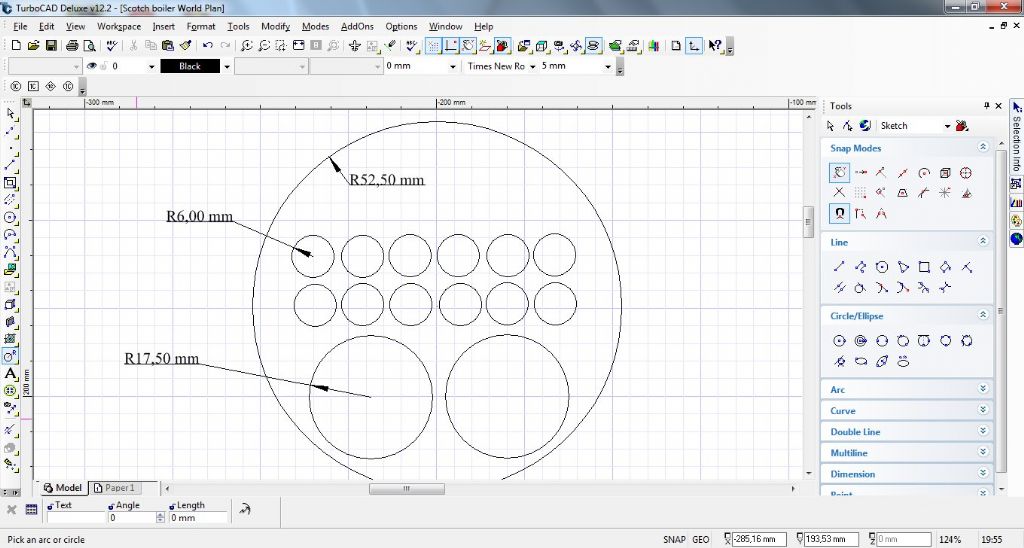

Boiler #1

Furnace: 35 mm diameter x 1 furnace

calloway: 10 mm x 7 tubes

Flue tube: 10 mm x 12 tubes

Total heat of surface: 0,856 m2

Boiler #2

Furnace: 35 mm diameter x 1 furnace

Calloway: 10 mm x 7 tubes

Flue tubes: 15 mm x 8 tubes

Total heat of surface: 0,856 m2

In case: flue tube: 15 mm x 12 tubes will give total heat of surface at 1158 m2

Best to calculate the heat of surface first before you are planning to make the boiler. Also larger heat of surface will give more steam and short boiling time from cold water to full steam pressure. Prevent to use too thick wall tickness in flue pipe and furnace due loss of heat. I am using 1 mm wall tickness in flue and furnace while the boiler 2,5 mm thick. Insulate the boiler to keep boiler heat enough to produce more steam.

I will recommend you to buy the book "Model boilers and boiler making" by K. N. Harris, there is a lot of information about boiler and how to design and make the boiler.

Russell Furzer.