Sometimes you start to wonder whether something you have been doing is a waste of time. This is the case where you know that you have no (or very little) 'expertise' – but where you do have some 'experience' (and there is a difference between the two states).

Since some of this thread seems to contradict my actual experience – I looked further. This paper gives more detail about cast irons and their properties: http://www.heat-treat-doctor.com/documents/CastIrons.pdf

"The most common heat treatments applied to gray cast irons are stress relief because of non-uniform cooling of castings and annealing to improve machinability. Subcritical heating is used for both. Stress relief is done at temperatures between 1020 and 1200˚F (550 and 650˚C) without significantly lowering strength and hardness. Heating at temperatures between 1290 and 1400˚F (700 and 760˚C) lowers the hardness for improved machinability."

"Ferritizing (for the most ductile microstructure) is done by austenitizing at 1650˚F (900˚C), followed by holding at 1290˚F (700˚C) to completely transform austenite to ferrite and graphite."

Elsewhere I discovered that dried oak can burn at up to 1600F.

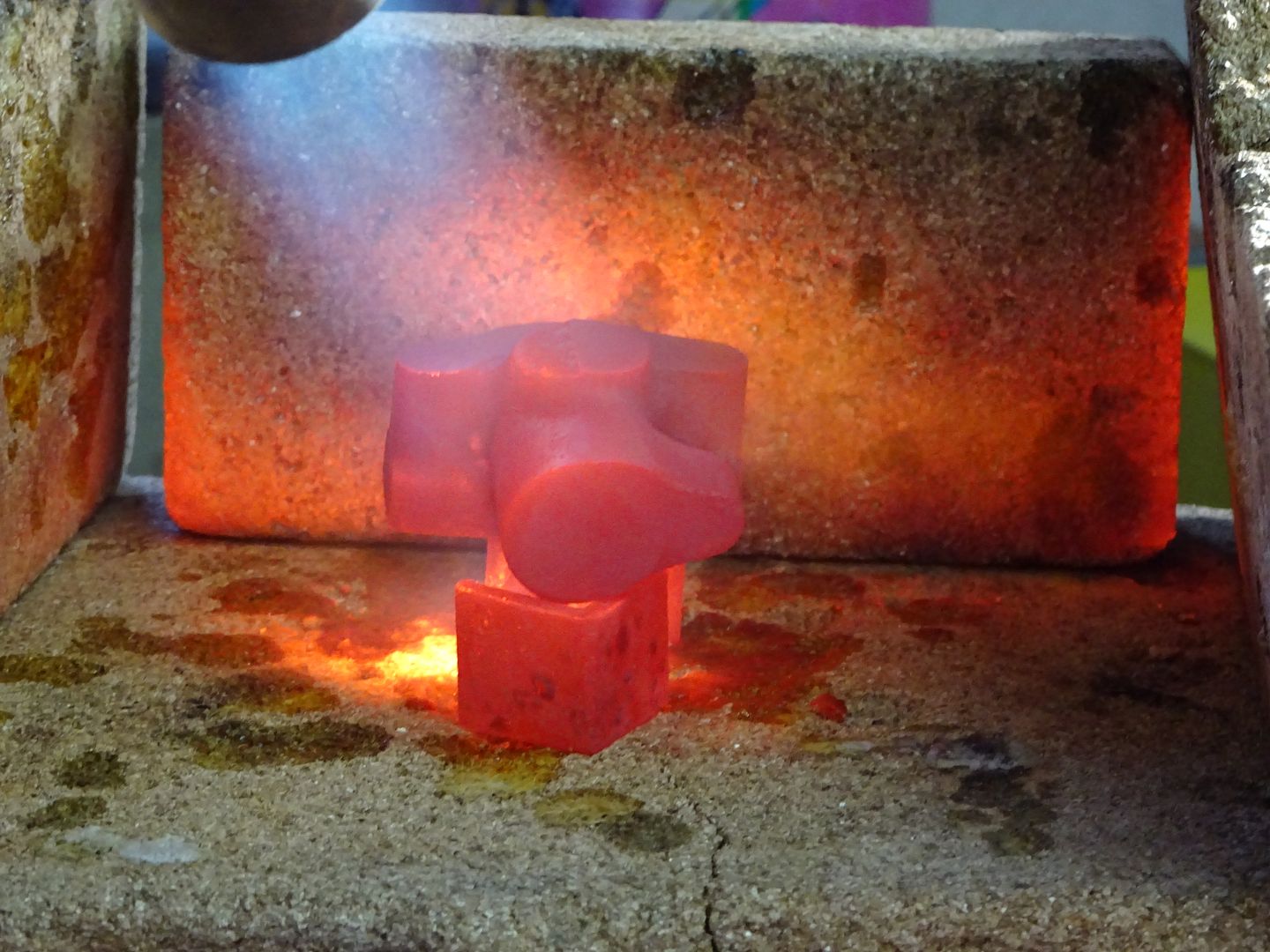

Well, I'm mostly burning dried apple wood (my trees grow faster than I can cut them back) and the incinerator has vent holes around the base and there is usually a bit of a wind blowing here. So this is not like using a (slow burning) wood stove – I put a lot of wood into my incinerator during an evening and it burns fast and gets really hot – I don't know how hot – but I have no doubt that it gets things easily up to the red heat shown in the photo – and holds it there.

So – I whilst I don't know if I'm getting up to 1650F/900C – I do think I'm getting them hot enough to effect some change – at least that is my experience. I'll leave it to others to worry about whether I'm only just 'annealing' and not actually 'ferritizing' – since it seems to work for me in practice.

Regards,

IanT

David George 1.

David George 1.