For plastics I tend to run at the same spindle speeds as steel, but increase the feedrate by 4 or 5 times. On the Bridgeport I simply use the 'rapid' button rather than faff around with the feedrate control.

The main issue with tool changing is accounting for the offset in length between tools. To set the scene I assume that we don't have an automatic tool changer and that the spindle has a repeatable chucking mechanism, ie, the tool always goes back in the same place in terms of Z. If it doesn't then all bets are off.

Of course the exact command sequence will depend upon the control system. But the basic G-code for a tool change without offsets is:

T01 M06

This asks for tool 1 (really aimed at an autochanger selecting the tool in advance) and M06 instructs the system to load tool 1. On my CNC mill the program simply stops at this point, one changes the tool manually and then hits the 'cycle start' button. But before doing so you need to change the Z value to reflect any difference in tool length. I used to do this manually. The first time I ran a program I would reset the Z=0 reference with each tool change and write down the offset. Then at each subsequent run I'd just type the numbers in as required. This got tedious for two reasons. One I got fed up chipping carbide cutters when touching off on the work or fixture. Two, if you forget to type in the number the results can be spectacular. Like burying a M3 tap 20mm into the hole before the spindle has started.

For these reasons I started using tool offset tables and also bought an electronic tool height setter. I use a master tool as tool 0 and use that to set the fundamental Z=0 reference. Then I use the tool setter to semi-automatically fill the tool table with the offset of each tool in turn relative to tool 0. The tool table can also be filled by measuring the tool lengths off line and typing in the numbers. The code for a tool change with tool table is:

T01 G43 H01 M06

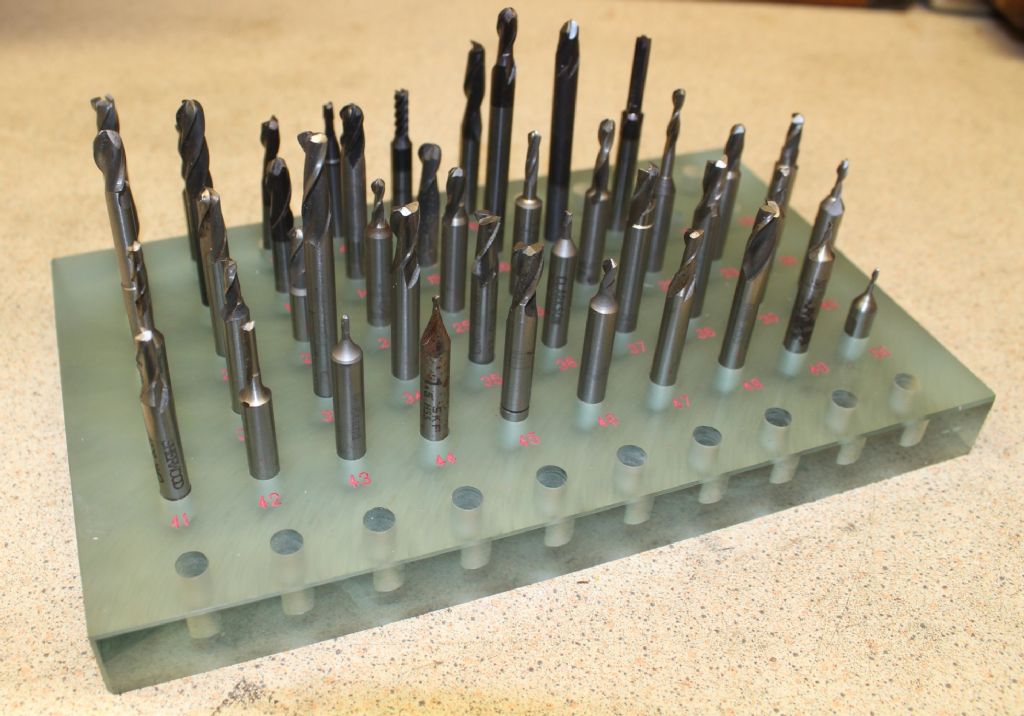

As before, except the G43 tells the system that rhe tool offset is positive, ie, added. The actual tool offsets in my tool table are negative as the tools are all shorter than the master tool 0. Tool 0 is the one on the left:

The H01 tells the system to look up the offset entry in the tool table for tool 1. In theory simple, but the hand hovers over the emergency off the first few times!

Andrew

JasonB.

JasonB.