I am with Roy Entwistle on this one, re posting :11.03.2019.

"If you are wanting to cut thin metal occasionally then whats wrong with a piercing saw? If you want to cut thin wood then either a coping saw or a fret saw"

Roy.

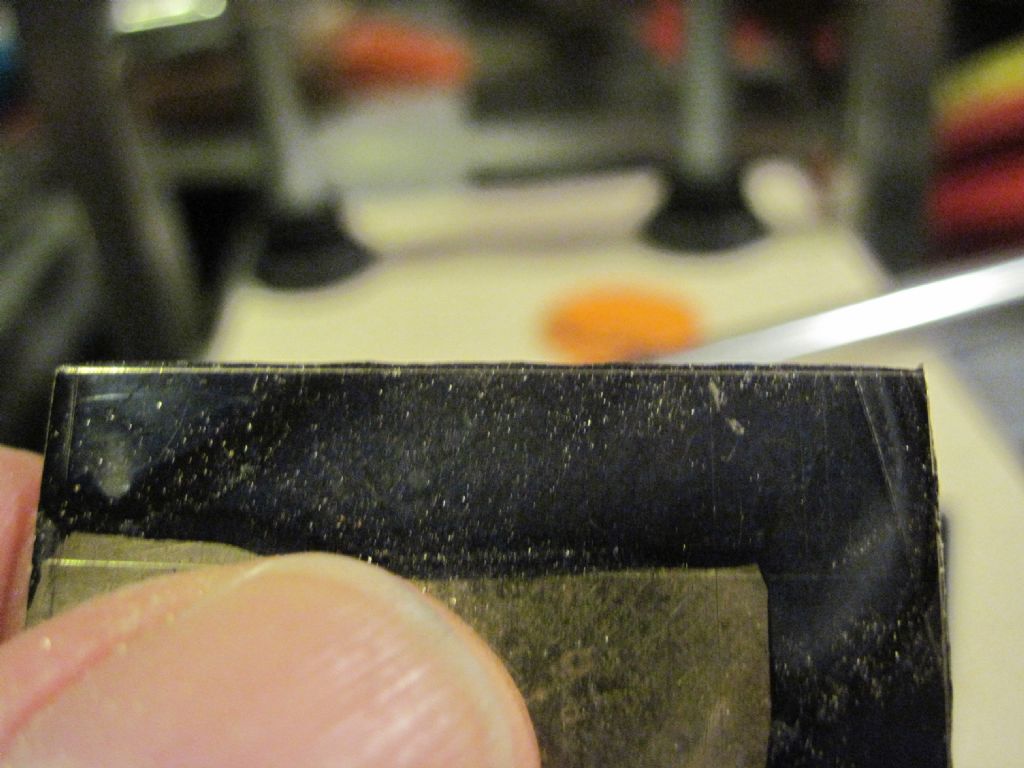

I will say however that the blades are inclined to break very easily because 'hand' control is not steady, but I found a simple way to help save the blades and I have cut 8mm mild steel for at least an half inch length before the blade had had enough.

It doesn't sound much but the alternatives are either drilling bashing and filing or going in for something expensive which could cause the 'Marital' arts to become the 'Martial' arts and the blades come in packs of about 10 and are quite cheap.

The saws do have a tendency to wander which doesn't help in keeping the blade in piece.

Picture shows piercing saw cutting two sandwiched pieces of 4mm mild steel for Mogens Kildes Double Diagonal Engine, the saw frame top rests on an engineers clamp which is inclined to give a guided cut in the right direction.

…Bob..

Ian S C.