I use a Portaband for cutting metal by hand, both straight and curved cuts, generally on thinner material that does not need to be clamped.

For cutting heavier pieces, I have an inexpensive generic horizontal bandsaw, but it does not cut straight, and it not very reliable.

I wanted a machine that would cut larger pieces unatttended, and something heavy duty enough that it would never stop working or need adjustment.

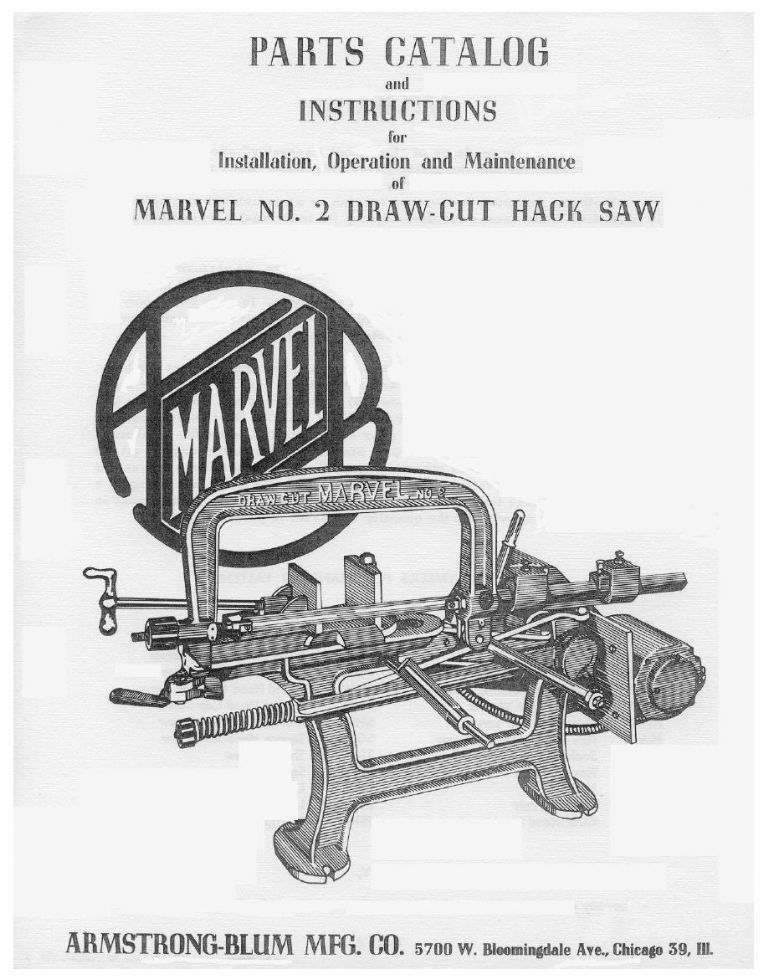

My solution was to buy a Marvel No.2 draw-cut hacksaw.

I am going to change the motor from 3-phase to 1-phase (I don't want to use a phase converter or VFD).

There is a video of someone online that has the exact model, and he rebuilds it, so that will be a great help with changing the motor. I am missing a few tensioning parts, but I can fabricate those.

The cost was $400, and about 2/3 more for shipping, but I think it will work out well, and it does not seem to have much wear and tear on it.

I will post some photos in a minute.

I don't know this individual, but he does a good job on rebuilding his Marvel.

He is what we call in these parts a "Good ole boy", but he has talent.

The part of the video at 4:37 makes one want to yell "Just Say No to Crack !!".

Edited By PatJ on 17/03/2019 22:57:25

martin perman 1.