The Stepper addition to my EMCO rotary table went well as seen in my various post, but as usual when pushing the envelope with steppers, high rpm and harmonic vibrations are a problem. Not wishing to try find a DSP type stepper driver with active harmonic control ( such as Gecko, etc) I went mechanical..A Rattle harmonic damper, and was most pleasantly surprised. Since the Rotary table's intended use was as a synchronised gear blank drive on a gear hobber, the table's speed is related to spindle ( hob) speed. In my case, the stepper drives the table with a 40:1 ratio.

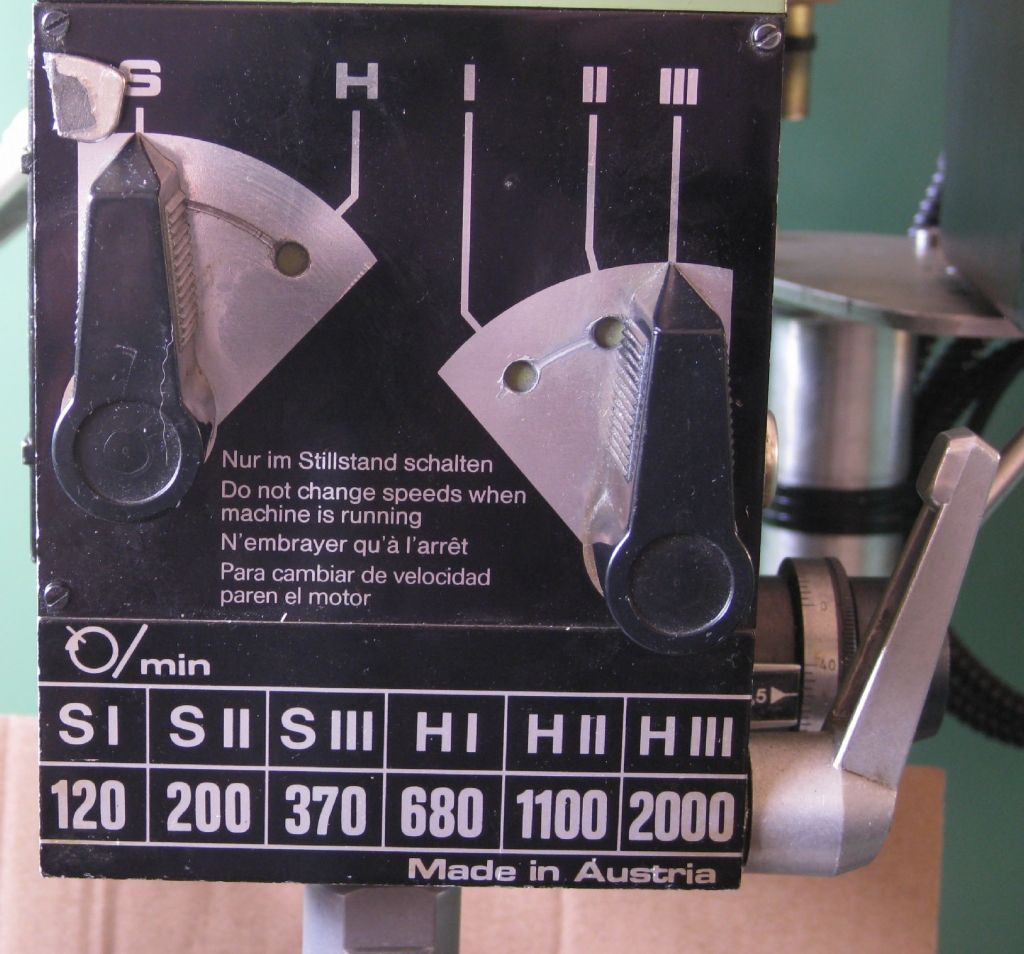

So, for example, if the Hob spins at 370RPM ( a midrange speed on my mill spindle), and we are cutting a 14 tooth gear with a pitch of 2.5mm, the stepper must spin at approx 1060 rpm – not easy to achieve with the table inertia, friction, etc.

I got close to this by playing with stepper driver voltage, up to 60 volts, and current, but the 370rpm setting was simply not possible. I made up a simple damper, as in the photos, and it works so well that I can even reduce the supply voltage down to 40v with no stall or loss of steps.

I made a rather miserable video, but it gets the idea across..

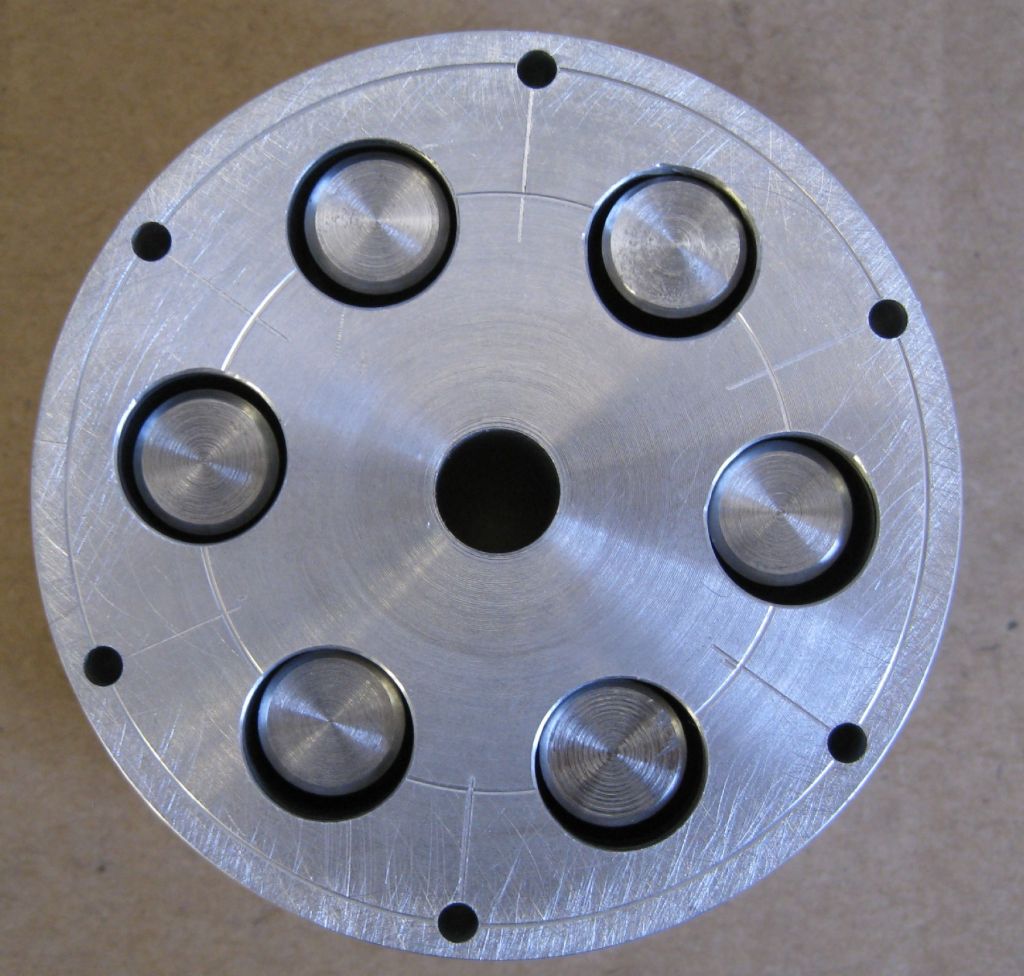

The wheel is 60mm OD, 20mm thick aluminium. The slugs are 10mm OD, 18mm long, mild steel.

The holes are 11mm ID.

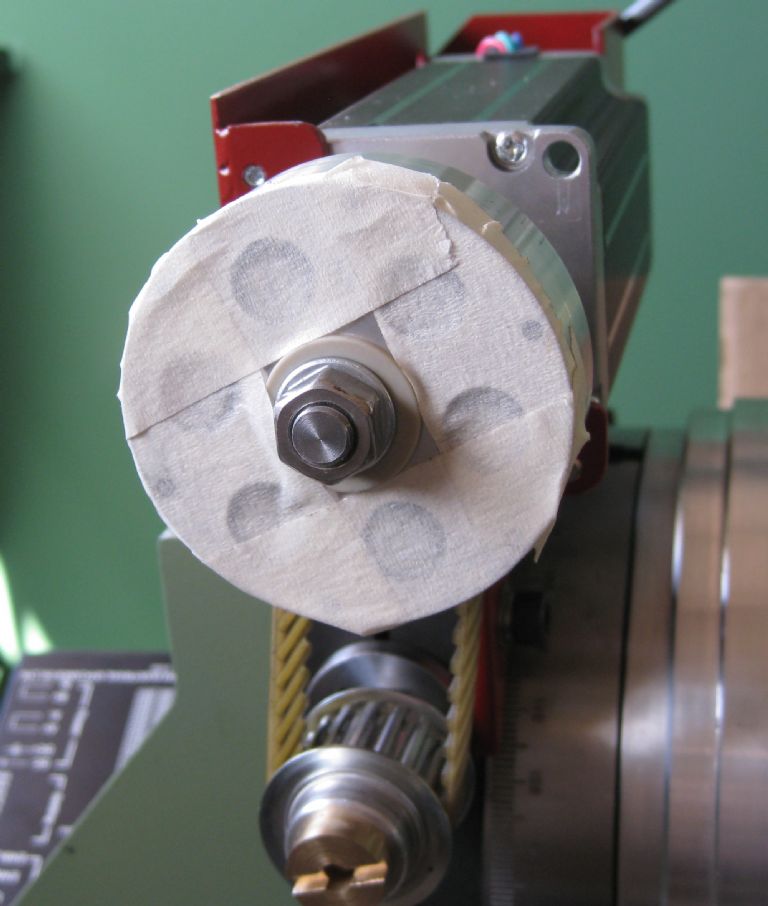

I just covered the slugs with masking tape for the tests..

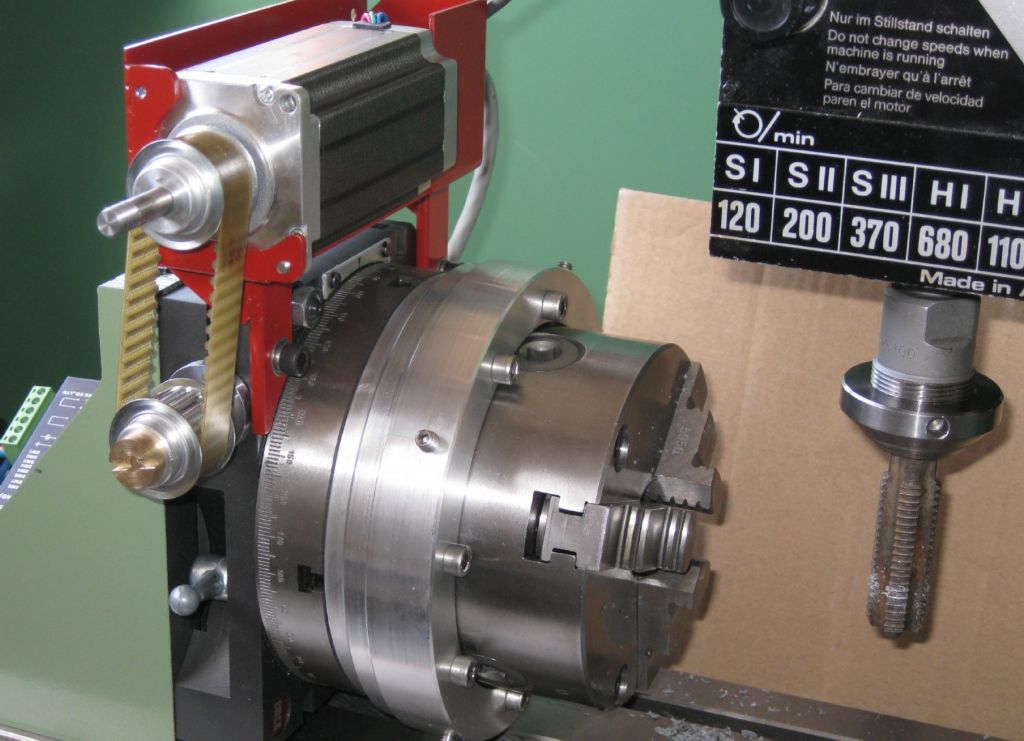

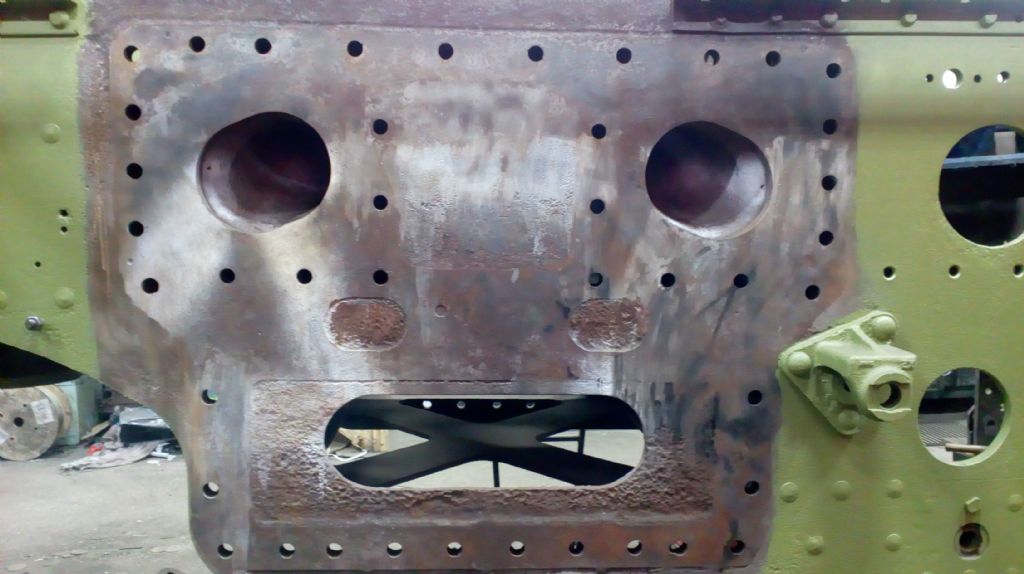

This shows the damper wheel mounting position.

The three speeds at which I tested the damper – 120rpm, 200rpm, 370rpm.

The video…Sorry, the start seems a bit mucked up..

I did three tests, first with the damper at the three speeds, then with the wheel but without the slugs, then with the wheel completely removed and then the 120 and 200 rpm speeds still work ( 200 does stall once in a while..) but the 370 does not work at all. At 40v supply even the 200 RPM speed fails without the wheel/damper

Joe

Edited By Joseph Noci 1 on 07/11/2018 16:58:31

Tim Taylor 2.