Posted by Neil Wyatt on 26/10/2018 21:32:45:

…

Do you know if they work on things like FETs or IGBTs?

I'm using mine a lot at the moment to sort out my muddled collection of components. While I was sorting transistors into NPN and PNP it successfully spotted a 2N3819 was a JFET.

The various adverts on ebay suggest there are a few variants about. I think the original LCR, NPN & PNP, & Diode unit has been extended and/or the software upgraded. If buying one, may be worth checking the detailed spec to see if you can pick out the most up-to-date model available.

In operation, the unit is a little erratic, and it is sensitive to dirty leads. Mostly I'm impressed.

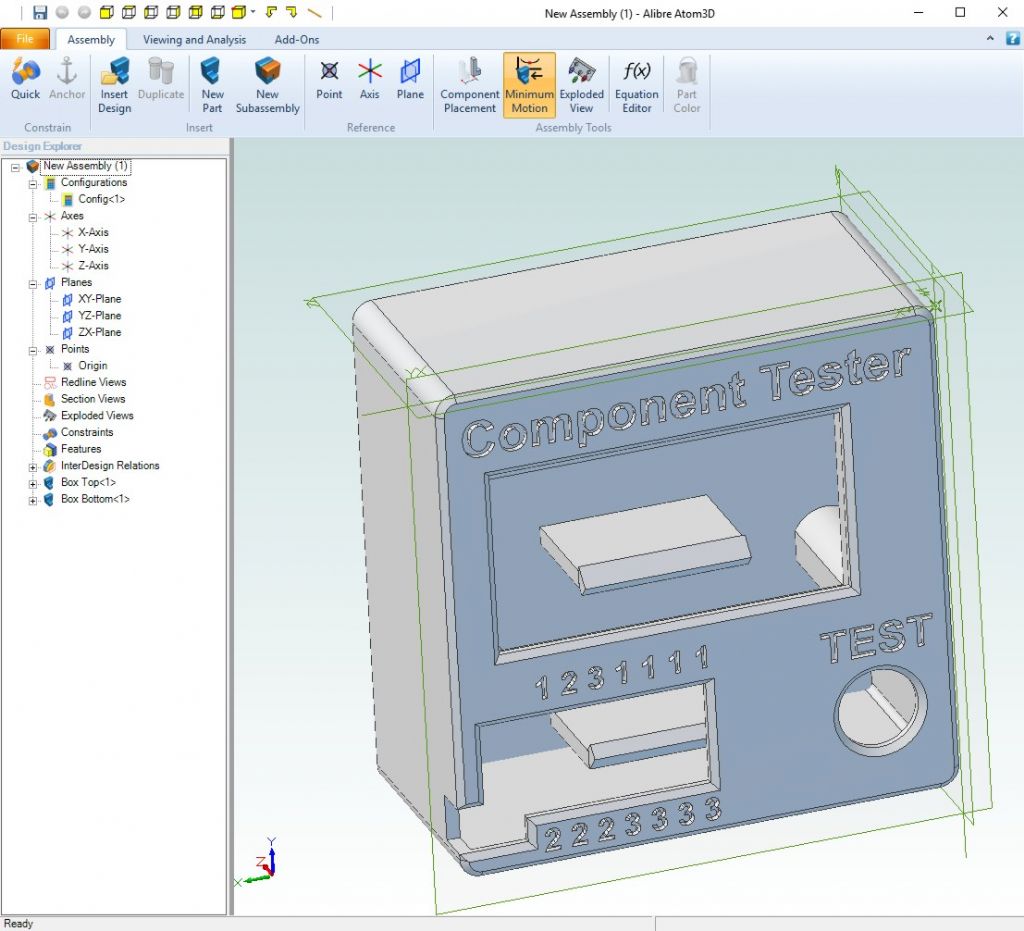

I use mine without a box and what with the battery flopping about and all, it's not a good idea. Making a box with my limited sheet metal / plastic instrument box technology is bothersome because of the need to provide access to the display and especially the DIL socket. A 3D printer would solve that easily – I want one!

Dave

Tim Taylor 2.