I've been doing a little more restoration of the full size Burrell Showmans Engine. After drilling through the centre of the flywheels six inch long key, then using the Oxy/Acetylene torch to burn it away, the four feet diameter flywheel was finally separated from the crankshaft.

………………The crank was then mounted on our large old lathe, the worn and scored main bearing surfaces were then skimmed and polished up. While in the lathe all the old paint and rust was removed, it's amazing what dirt and filth some people will paint over.

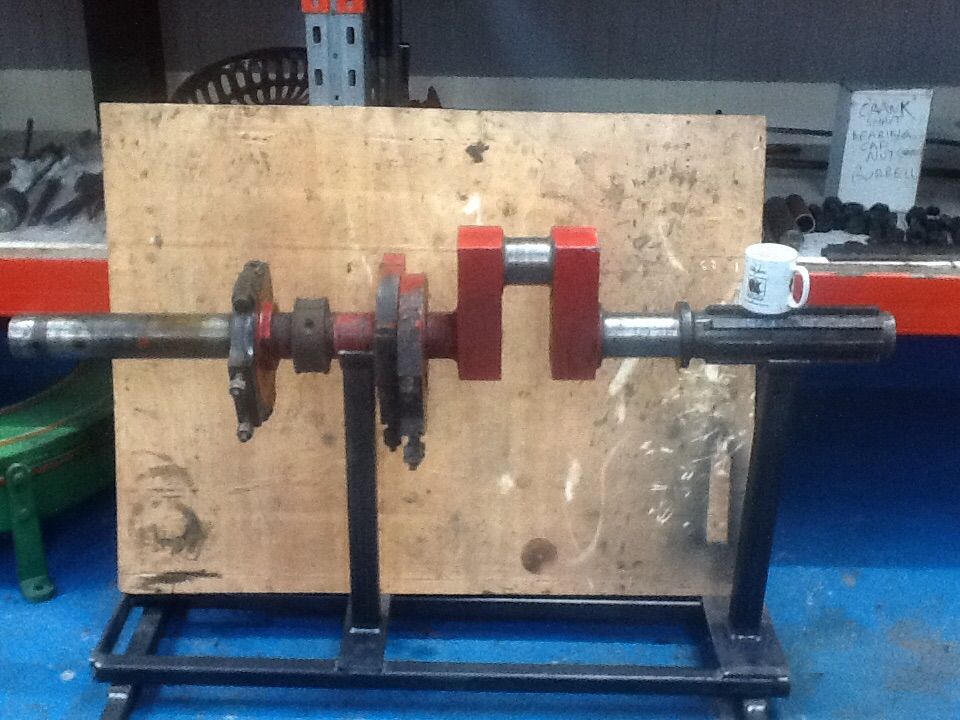

………………..The 78mm big end journal was in a bad state, badly scored and worn barrel shaped with a diameter measuring 1.3mm larger in the middle than the sides. It had also worn into the large radius in each corner. It could not be set up in this lathe to machine the crankpin, so I was all set to crate it up and have it sent away for regrinding. But in the end I decided to have a go at it with the crank mounted as shown. .

.

………………..After several hours work using hand tools and strips of abrasive tape the big end was restored to a smooth, parallel and round journal, quite tricky when rotating with a 12 inch stroke.

Tim Taylor 2.