Back to the crash I had an ignition switch for the mags but hadn't pushed it far enough now you have a plug you pull with a cord.

Left my bike clips at home, Damn.

When I was doing my record bike thing you dreamt about sponsorship but in reality it was at a cost.

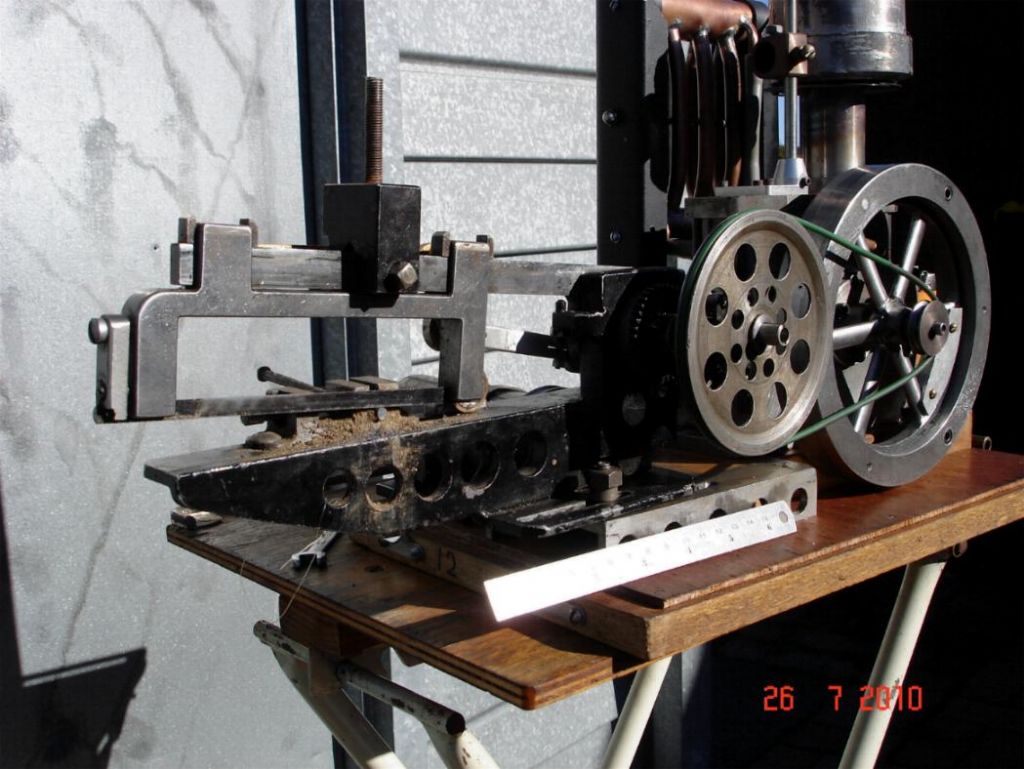

I was surprised when a phone call at work from the editor of a motorcycle magazine said he had a chap who wanted to give me some money to try to help with a transmission problem.

To receive money from someone you do not know with no conditions was an eye opener.

Unfortunately family health problems came first and speed record attempts lost its importance to me.

To a person who tried to be self sufficient apart from the help local friends used to give it was a revelation that offer of money.

To find genuine people is great when some are only after what they can use you for to make money.

Being back in the full size speed scene the genuine help that is offered gives you faith in human nature.

JasonB.

JasonB.