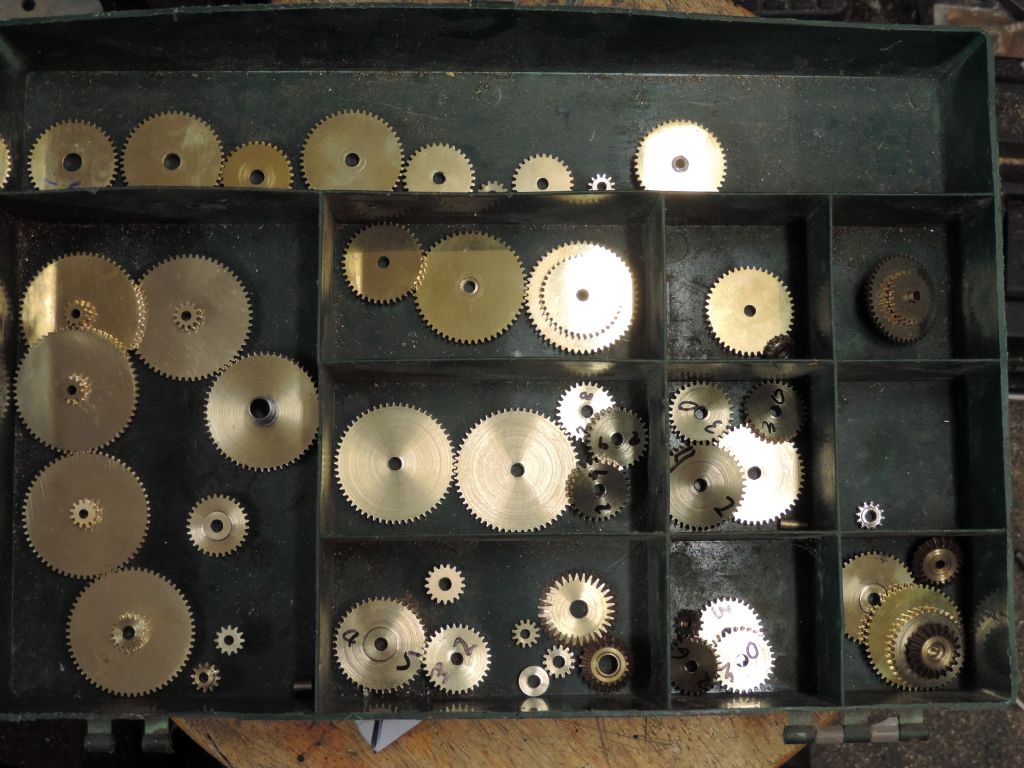

What did I do today? realised that I now have to start fitting together the three-dimensional puzzle that my Jovilabe has become. But I have been a busy bee generating huge quantities of brass swarf over the last few weeks. This box doesn't include the various failure gears although the partition at centre bottom is perfectly good ones that turned out to be too big/wrong number of teeth etc.

You can see some are highly polished, some are ready for polishing and some are straight from machining. The sharp eyed will see some have nicely formed teeth and some (at reduced PCD) have slightly skinny teeth, but aside from the bevels I'm sure any gear in this box runs happily with any other gear. (The bevels are a spare pair left over from Norden that I made with bosses of the wrong size, but ideal for this application).

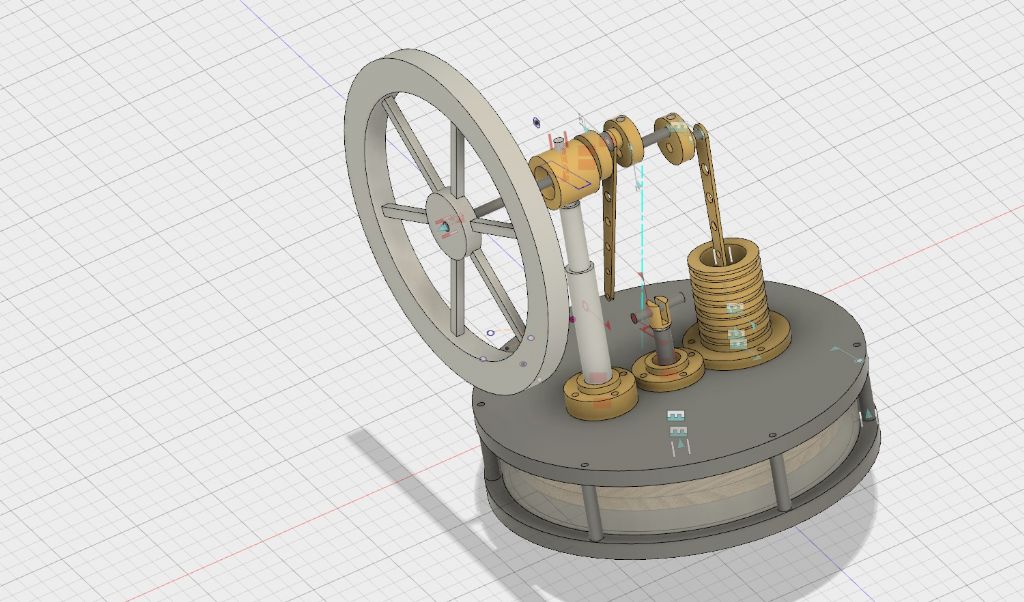

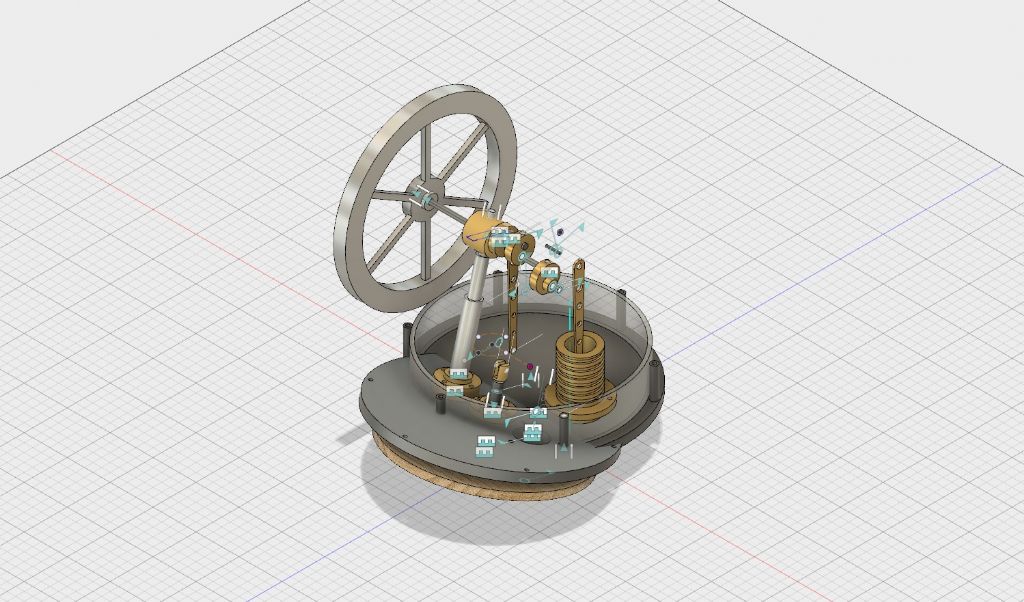

The challenge for assemble is that many will have to fit on 3/16" tubing on stationary 1/8" stainless spindles, a few will go on moving spindles, and the ones that drive the planets will be on telescoped tubes. One gear will go on a stainless steel cylinder that fits around the massed brass tubes and runs in the front plate.

Challenge now is making sure there are no clashes (so far only one found, easily corrected by raising a gear, phew!) and arranging support for any spindles that would interfere with another gear. This may involve a greatly pierced intermediate plate or several short cantilever arms which might look better. I can then build up the mechanism and decide how deep the frame will be.

Yes it will have more gears than the Antikythera mechanism, so I hope it works!

JasonB.

JasonB.