I bet if you round the corners of the internal teeth as if they were the roots of the tooth spaces on an external gear, you will be able to assemble them

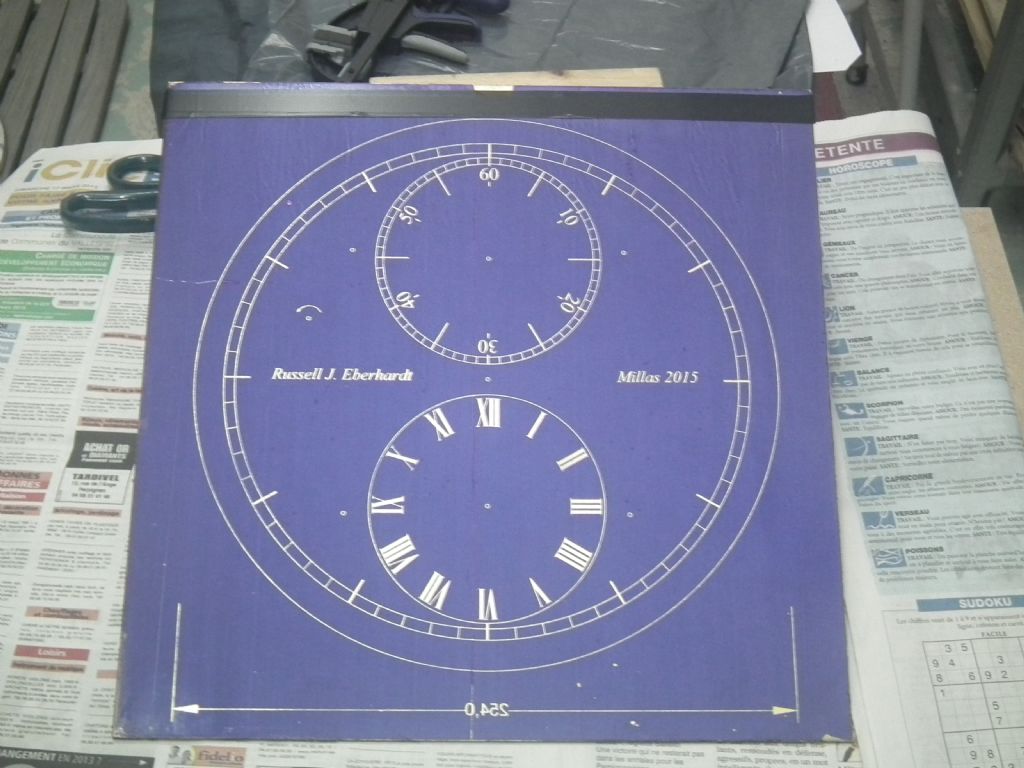

Today I tried using photo-resist film. the supplied instructions were totally useless – they didn't mention you need heat to get the film to stick!

Try 1 – whole film turns purple. UV doesn't make it come off???

Try 2 – same problem – realise it's too much heat, I realise now that if the film turns purple it has overheated.

Try 3 – use less heat, but when put in the developer the result is negative! This film turns hard when exposed to UV, while the spray/pre-treated boards I use its the UV-exposed bits that disappear in the developer.

Try 4 – use negative artwork. Is it etching? it hasn't gone the usual pink… back in the developer Oh dear all the resist has started to come off… oh look you can see where it's etched a bit, but somehow this type of brass doesn't go salmon pink!

Try 5 – This should be perfect. oops didn't hear the timer because I picked up my guitar. Looks like it's developing OK… except all along that side where it's all over-exposed.

Try 6 – at last! A decent mask, in the etch at last!

I'm glad I decided to practice on a 30mm disc before trying the 240mm one…

Tomorrow, find the exposure time under fluorescent lights – my UV box is only 6" wide…

Neil

JasonB.

JasonB.