To get clear, I'm sorry if offends anyone that I still have not actually done the bonding, but my 2 sheets are deply buried under projects.

MichaelG – Noted. My main problem is that I would need to go and buy some A0 material and get it cut to size. It would also add unwanted weight onto 2 already slightly heavy boards. I'm assumging honeybomb wont offer enough tentile strength to resist any pre-existing warping. What do you think is the thinnest material (e.g. MDF/plywood) that I could get away with that would absorb enough moisture to allow a wood glue to set?

MichaelR – Magnets won't bond over nice large surface area (to help flatting any warping), will require the melamine to be drilled into. Ultimate flatness is the primary goal here not ease of shifting the A0 MDF sheets.

MichaelR – No, the problem with adhesive tape is that never sets. Over time, any bowing of the material would re-establish itself. Ultimately, I just want to bond melamine to melamine.

So back to my question ideally I really I just want a glue that sets to bond Melamine to melamine.

It would be nice if the glue shrank at least slightly as this would help pull the 2 surfaces together. (In fact best of all would be if the glue shrank to zero thickness and just bondind the two sides together!). But I am happy to drop the shrinking requirement if necessary.

Jason – Much though I hate CA, I concede that CA may well be the best way forward. It would certainly save me the bother of finding and cutting third sheet to fit between other two, that would be required for say wood glue.

Good to see you got a good bond. And hopefully one could still get a good bond right in the middle of a square metre or so (?)

How importantd do you think using thin strips are? And how far apart do you think that they should be?

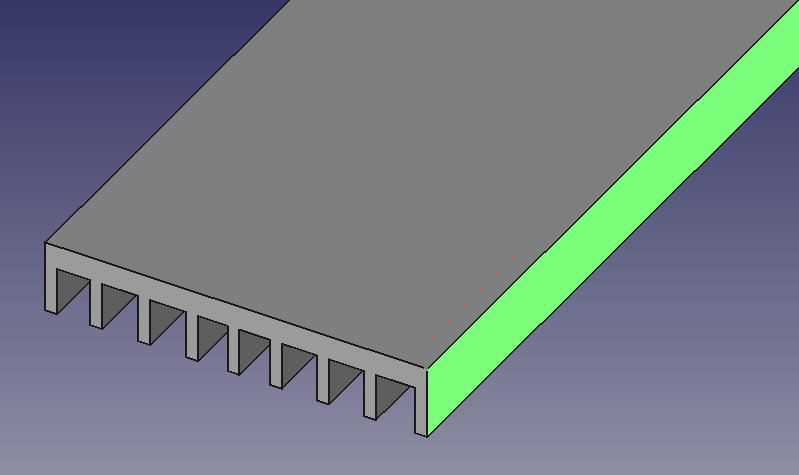

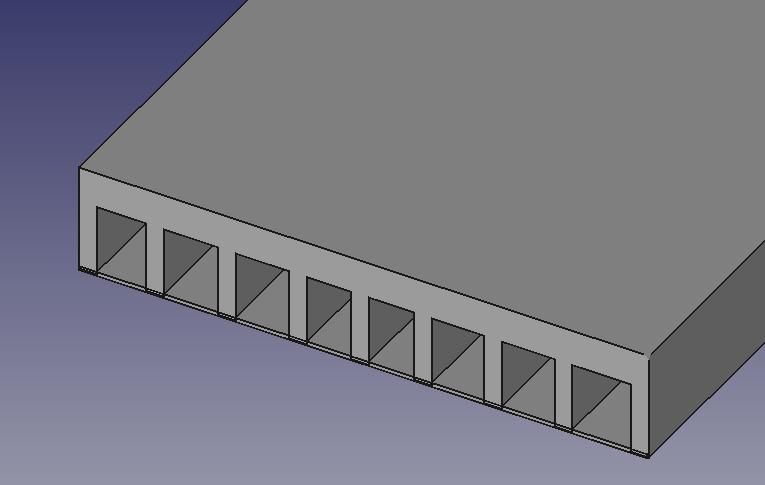

Thin strips will of course let help let the air out, help get an extremely thin layer of glue… plus in theory even let the additional moisture in the air diffuse back in (eventually).

That said, the problem with strips is that the melamine is such a thin/fragile layer it will need all the help that it can get to fight any bowing after the clamps have been removed. But I think if one ended up with strips of glue over c. 50% of the bonding surface area, that would be fine.

In your model I see that for much of the areas in question you seem to have acheived nice wide bonding strips… but that ends the bonding strips are very narrow. [And FWIW, this is exactly that sort of problem I personally always seem to get with CA!]

Nonetheless, CA may well be the way forwards. But I'll have a think. My boards won't be free to be bonded for at least another week in ay case.

I'm also still tempted by mixing up a load of Epoxy resin – at least I could guarantee it will set! On the down side even though it's so viscous that it would difficult to get it properly thin. So I guess that I would definitely still use strips though to let the air out and minimise the distance the the viscous glue would need to flow to… in order to overcome accidental lumps & bump in the application of the adhesive.

As well as applying the adhesive in strips, I would of also use a serated glue applicator to help apply the adhesive evenly, as well as to create micro-escape channels for the air to escape locally.

Don

Robert Butler.