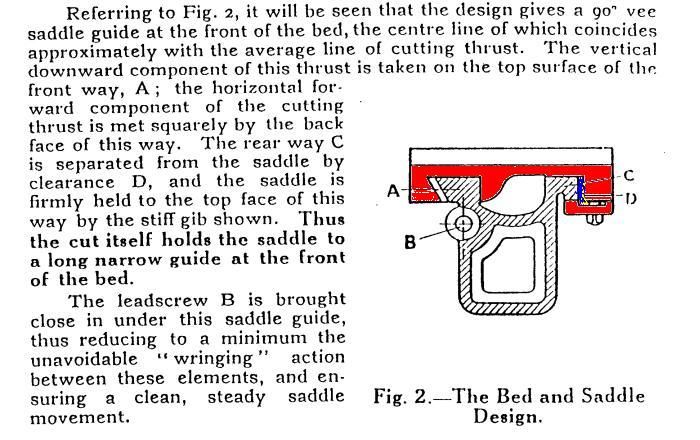

Michael G is more or less correct – it's length that sets the twist so a narrow guide needs to be long in relationship to it's width. It's one of the advantages of prismatic beds with an inverted V on top as guide.

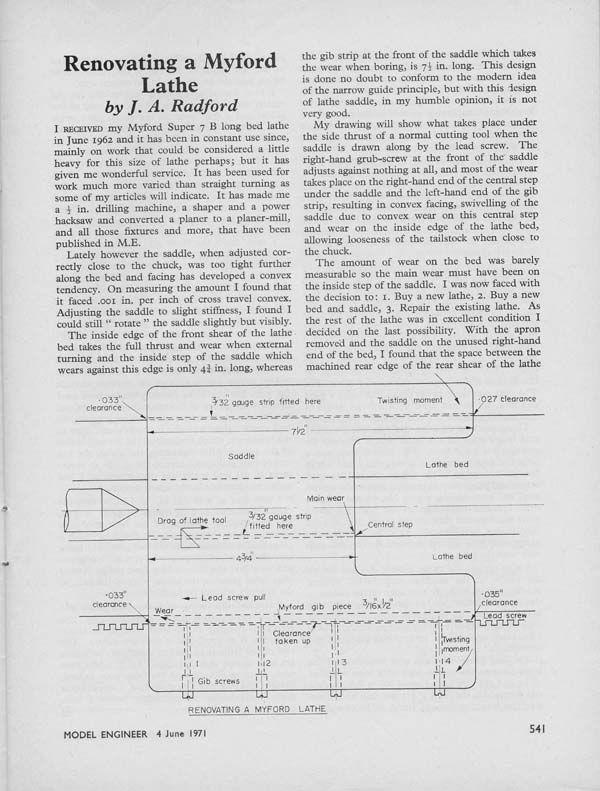

The not so narrow guide often occurs in dovetail beds. Sometimes the saddle is scarcely wider than the width of the bed = not a good idea at all even from a wear point of view.

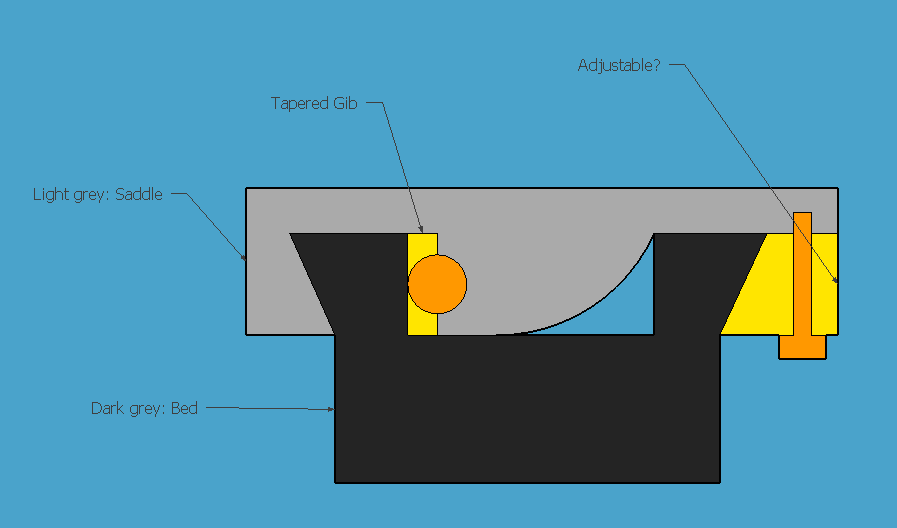

The Artisan is weird. The only way that can work well is if the gib causes the rear dovetail to be in good contact with the saddle. The front V isn't going to do anything but that probably doesn't matter providing cutting forces push the saddle down and against the gib / rear dovetail.

Doesn't make much sense. Might be drawn reversed and the bolt on bit should be at the front. The sort of unused dovetail half might be of use if the lathe was used for milling. Some don't like that as the saddle isn't held down.

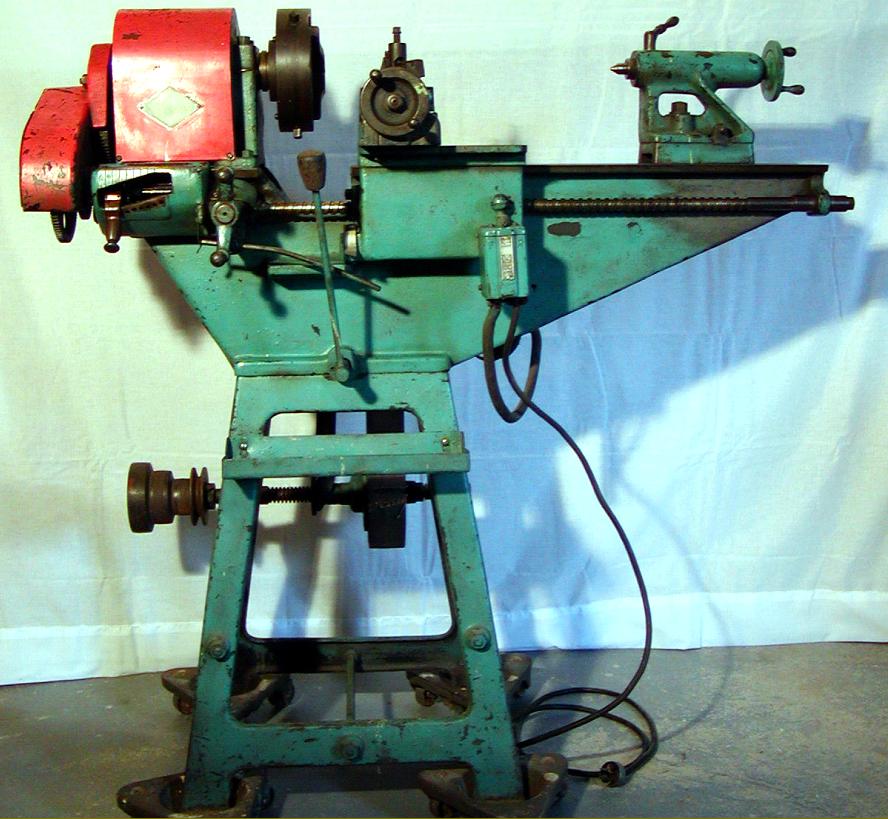

The cantilever wont matter providing it;s all rigid enough. Don't ask me what make but I did use a lathe that just had a pillar under the head stock end that contained the motor and drive. There were 2 of them. Swing probably about 12" maybe a bit more. They were decent lathes but looked rather odd. For size the centre distance was under similar sized lathes. Probably about 24".

John

–

Edited By Ajohnw on 13/09/2016 21:12:18

Ajohnw.