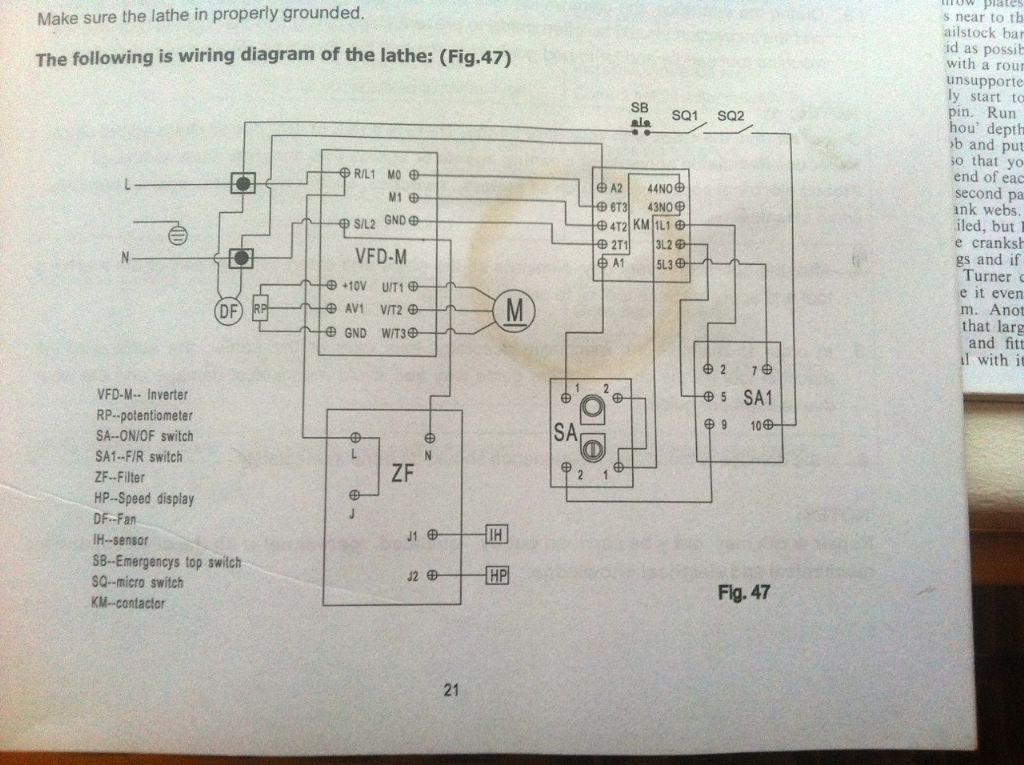

Having in the last few weeks taken delivery of my repaired lathe from WARCO who had fitted a replacement speed control board I was looking forward this afternoon to running it up and doing a little work.

All went well for about twenty minutes albeit with the start button making its usual stuttering and false starts. No worries though as long as the thing worked – and then – I pressed the start button and the breaker tripped on the consumer unit in the workshop. Oh no, not again pleeease!

Tried starting again six times and each try the breaker tripped. By now I was beginning to feel slightly sick that my very expensive repair was for nothing.

Next thing I tried was to plug lathe into the house circuit and tried again. Press start button, chuck revolves briefly then lathe dies. What the four and a half is going on I thought.

Decided to check front panel fuse, it had blown. Replaced it and tried again. Same thing, another blown fuse and once again for luck, another blown fuse.

Replaced fuse, disconnected lathe from house circuit and plugged it back into workshop circuit. Pressed start button and the breaker tripped. Checked front fuse – it was still OK. Repeated several times with same result.

Apart from calling WARCO on Monday I am once again up a gum tree with a duff lathe again.

With the WM250 V-F out of its twelve month warranty but still under two years old from new I am reluctant to spend yet another £277 (or maybe more) on another repair which may or may not work.

Anyone want to buy a s/crap lathe?

Rik

mechman48.