Posted by

Graham Williams 11 16/08/2019 17:19:26

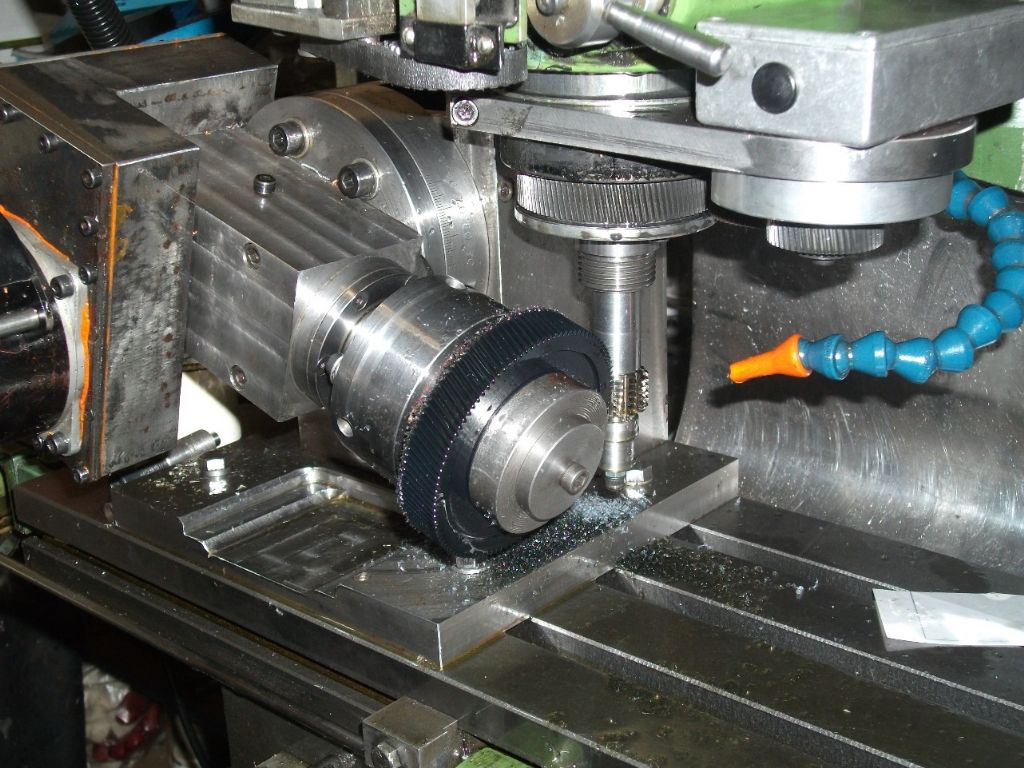

Wonder what a small gear hobber will cost to make……….. where is this going?

An article published in MEW 193 Sept 2012 Shows an electronic system

which is still available from Richard Bartlett ,as of last year he still had 12 of these

available in pcb form.The article show the mechanical parts that i made and will cut

spur and helical gears of any tooth number.

Obviously this requires some amount of work and expense to complete to make

this unit and also finding an 0.8 mod or 32 dp hob.

These here sell hobs i have not bought from them so have no experience

of their service.

https://www.aliexpress.com/w/wholesale-gear-hobs-for-sale.html

Without knowing the exact specification of the gear ie 0.8 mod or 32 dp if the gears

can be hobbed the 0.8 can be cut using the pcd of the 32 dp ,i doubt you would be

able to tell the difference as the error will be less than the backlash.

The photo here is a 0.8 mod 17.5 deg helical gear for an align powerdrive unit.

The gear in your photo appears to have some damage on the flanks not unlike

the descriptions shown here in the second photo taken from a gear book, the

descriptions of abrasion and scuffing would seem to apply.

For this reason it would be unwise to make and fit some fudged gear and hope that

it will run in.

John

Chris Evans 6.