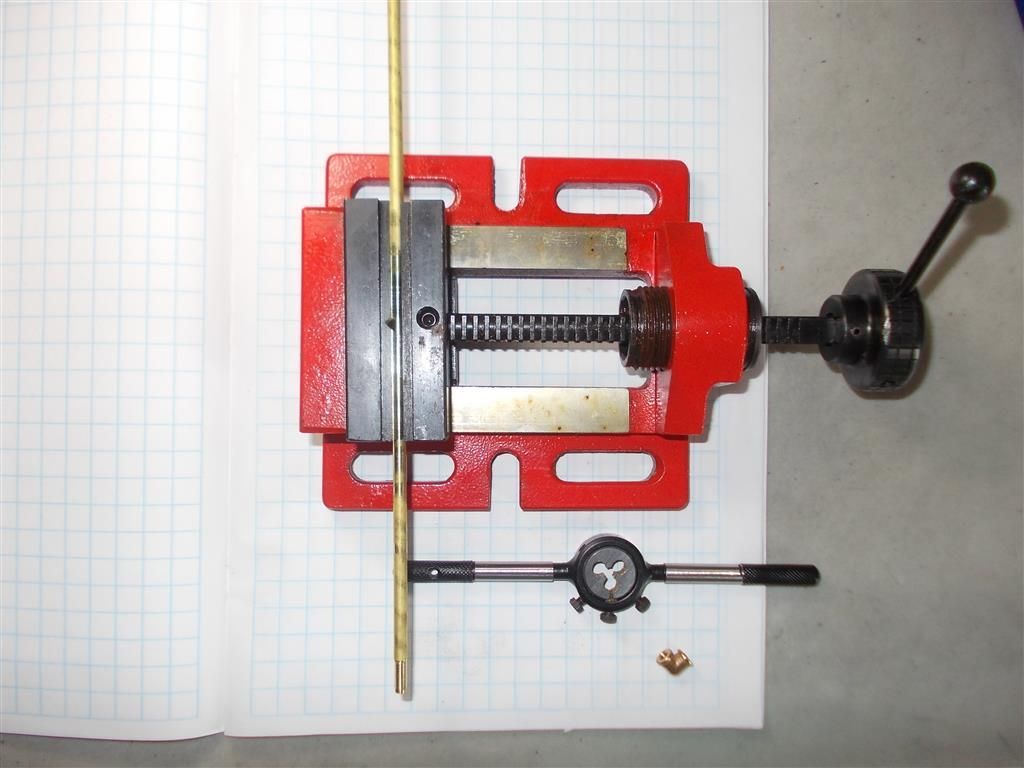

Success…I think ! I opened the die out as much as I could using the centre screw. I was still having problems with the brass tube turning in the vice but I persevered by turning the die stock back and forwards about 10 degrees left and right ( a see sawing movement). Eventually, things became easier. I overdid it a bit as you can see : far too many threads

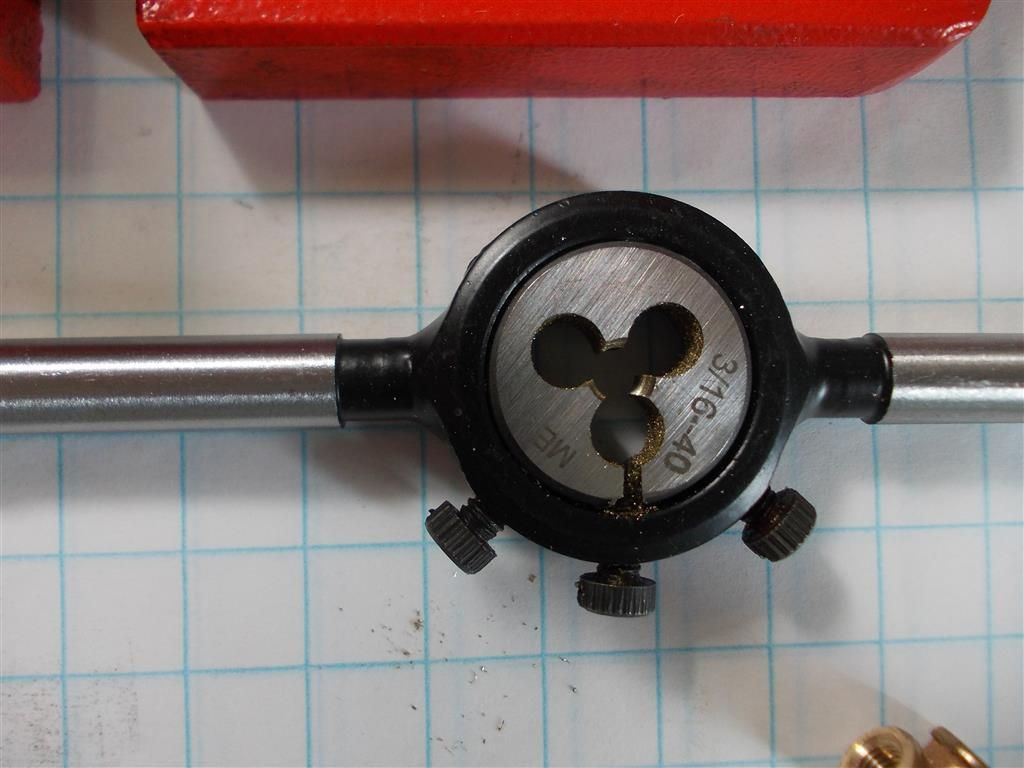

I think all my problems were caused by incorrectly fitting the die to the diestock the first time. As others pointed out, the centre screw was in the wrong place and this closed the die up too much.

1. Is that new vice okay ? As you can see from the top view the red base is not quite parallel with the jaws. I am not sure if this affects its grip ?

2. I have put a machined ell piece ( by PM Research) on the brass tube but it only goes on about two full turns. This seems to be the norm when buying machined parts as I have tested some of their other fittings with each other. These are straight pipe, not MTP. I thought they should screw on further than that ?

3. How do you clean all the filings from the die once you have finished with it ?

Edited By Brian John on 14/05/2014 06:04:23

Edited By Brian John on 14/05/2014 06:08:24

Michael Gilligan.

Michael Gilligan.