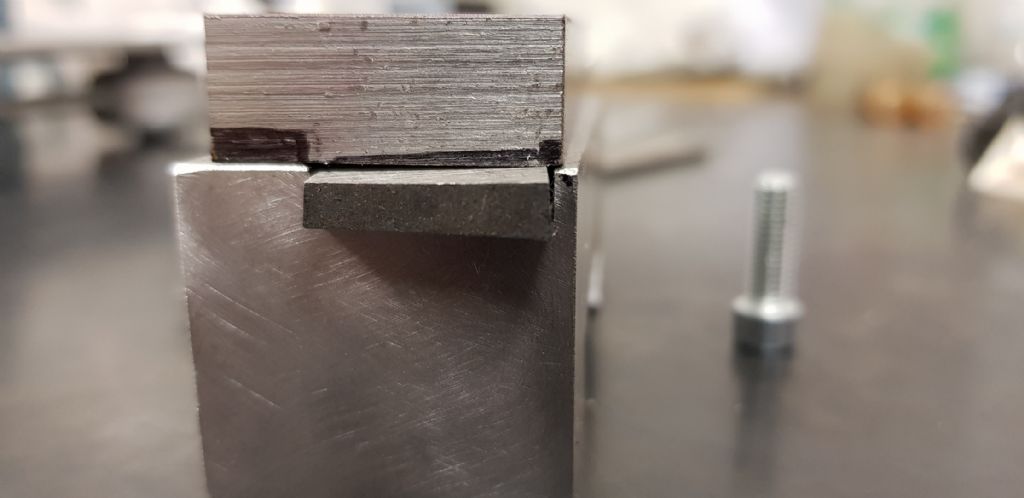

The factory Dickson toolpost blade holders use a full length bar of truncated triangle shape that simultaneously pushes the blade down into the bottom bevel and holds it back against the body. End on view in top picture shows the blade is held at the right angle to get clearance on both sides of the cutter as mentioned by Jason. Left hand one is a special wedge I made to use shallower blades in the Dickson holder. I had two sizes in my stash.

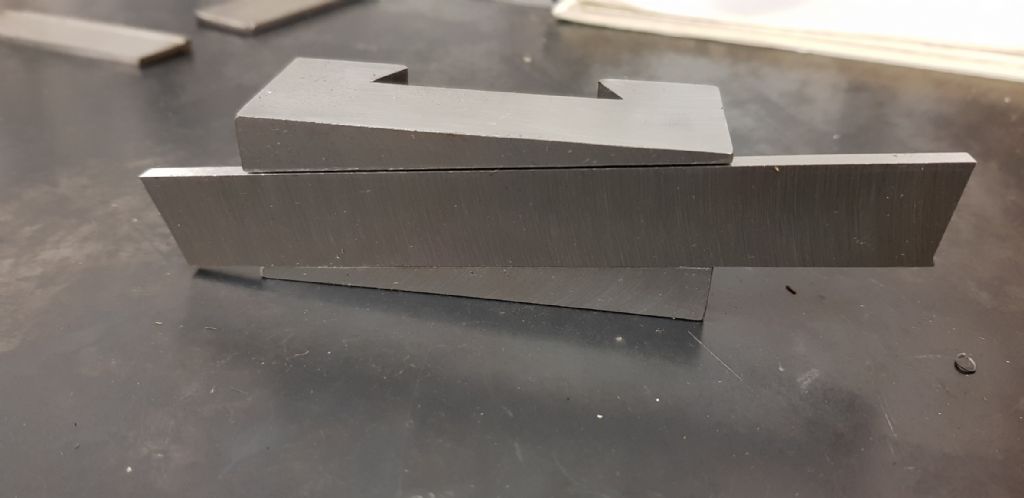

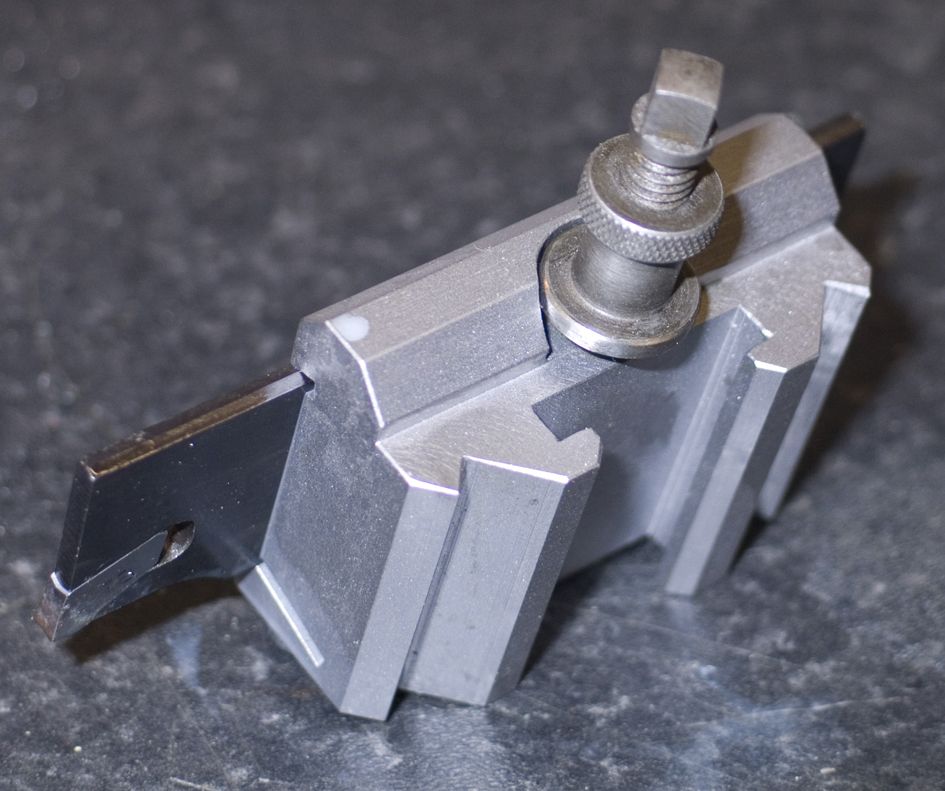

Generally the shallower blades are held in Armstrong style holders. These still have the full length bottom bevel but the actual clamp is much shorter so it can be fitted into the limited space in front of the four way, block or lantern toolpost. A full length wedge would make the holder impractically deep. Same sort of wedging principle. Common type mounts on an eccentric bolt so turning the bolt shank pushes the wedge down. Nearest thing to the factory Dickson is a short wedge with through bolt acting against a horizontal ledge at the top so the wedge pivots rather than pushing straight down. Easier to make but less secure as there is limited contact on the blade.

Possibly the most secure version uses a U shape wedging piece held down by two screws, mine has cap heads. The back of the holder has a slope matching the inner angle of the U wedge so as the screws are tightened the wedge pushes down and inwards on the blade.

I can take some pictures later if need be.

Clive

Edited By Clive Foster on 03/05/2020 10:56:42

Edited By Clive Foster on 03/05/2020 10:59:11

thaiguzzi.