Worn spindle bearings can cause chatter.

A more sensitive test is to just turn something with various depths of cut, Start heavy and then go lighter. The heavy cut will hold the spindle firmly up in the bearings and should give a decent finish if everything else is ok. This DOES need a very even feed otherwise the the spindle will drop down and leave a ring on the work. The same thing will start happening at some point as the depth of cut is reduced however even the feed is. The best material to try this one would be circa 2" dia free cutting mild steel with a a couple of inches sticking out of the chuck. It's a very severe test. If perfect the same finish would be produced what ever the depth of cut.

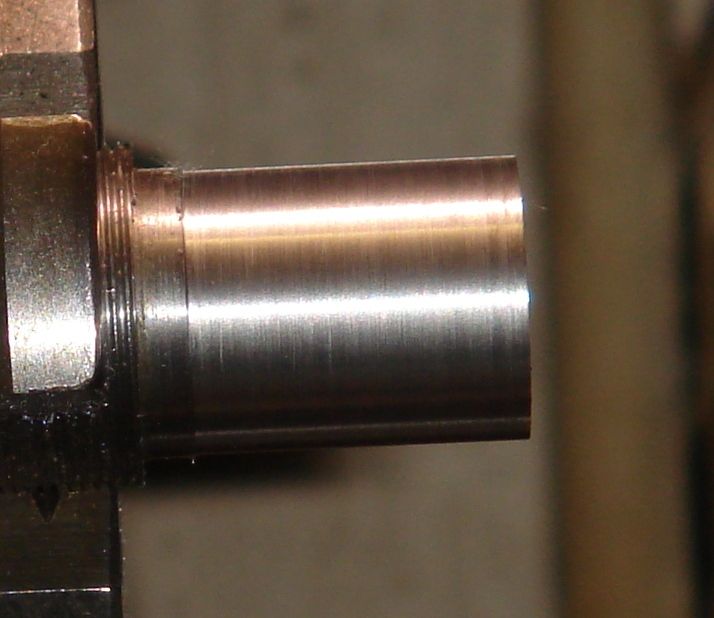

The other thing with sizes like this is gradually increasing re cuts as the tool is wound back to the start. Often a cut being taken several times each time the tool is run down the work. Deflection of other parts might give a minute cut more like scraping but a so so finish if the bearings are pretty good rather than perfect. Generally few lathes will give an excellent finish with super fine cuts and that can be just down to vibration. The marks on the work might only be a micron or so deep. This sort of thing for instance

A band can be seen periodically along the work caused by a wobbly large countershaft pulley. This was after the bearings had warmed up so everything is tighter than when they are cold which makes this sort of thing a lot more apparent. Junk silver steel in this case. There was a bit of tearing on the actual cut. It's very very shallow though.

If 2" of 1" dia was sticking out and a cut say 60 thou deep was taken the bar is likely to bend a bit due to the cut so the same cut will remove more material. More noticeable on the end of the work. If the work is lifting in the bearings a noticeable cut will be taken right from the start when the tool is wound back as the work will be evenly tapered. Loose bearings will also cause the lathe to turn a taper over and above it's inherent alignment.

People are inclined to put this sort of thing down to deflection when it's mild. I'm inclined to say really and leave it at that. What it boils down to is the most lathes need a certain cutting load to give the best finish they are capable of. This can be a wide variety of feed and depth combinations. The state of the bearings then determines what happens if the tool is just wound back or the same cut run again. The tool withdraws slightly when wound back on some lathes. It depends on the saddle fit and where the nut or rack gear is applying force to the saddle.  that can cause some strange accuracy problems unless the saddle is wound back until the tool is way past the end of the work or enlarged diameters right at the end.

that can cause some strange accuracy problems unless the saddle is wound back until the tool is way past the end of the work or enlarged diameters right at the end.

ML7 bearings can be replaced but Myford supply phos bronze now rather than white metal. I have heard of people casting them in place. I could run through scraping them if any one is interested.

John

–

Ajohnw.

that can cause some strange accuracy problems unless the saddle is wound back until the tool is way past the end of the work or enlarged diameters right at the end.

that can cause some strange accuracy problems unless the saddle is wound back until the tool is way past the end of the work or enlarged diameters right at the end.