Posted by Dr_GMJN on 25/10/2020 16:47:54:

Cheers Ramon,

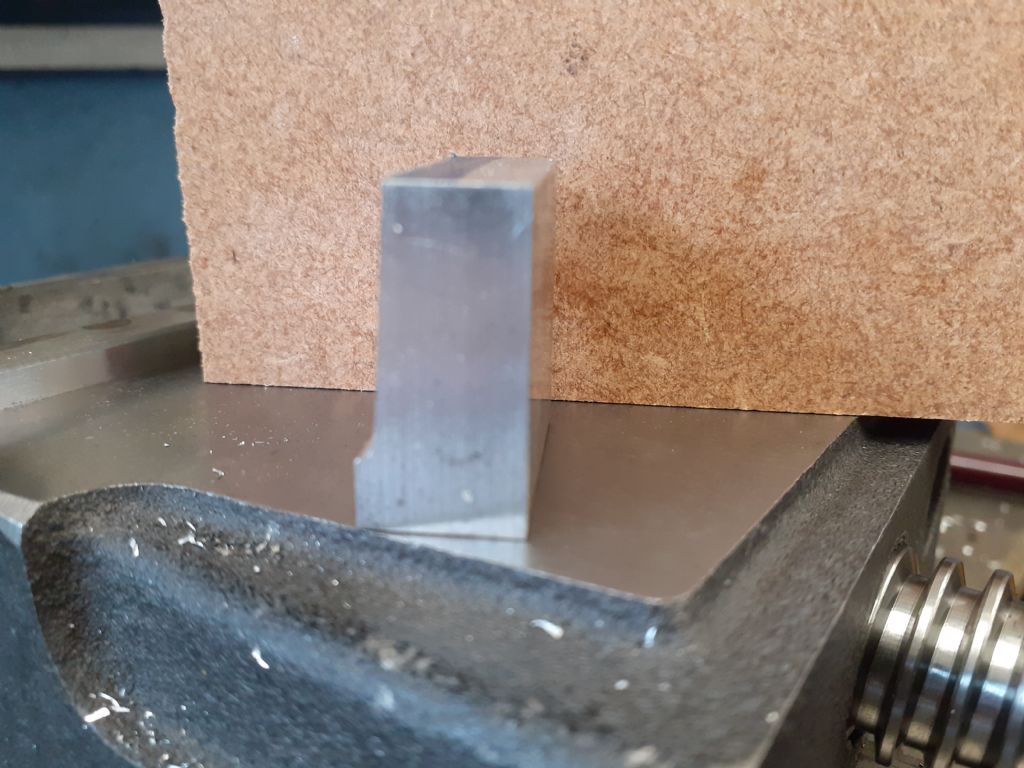

The spindle bearings are fine. The mill is new – or at least first got used this May after buying it last year. I can only think that the tramming process – using shim steel under the column bolts, doesn't give enough bearing area and is causing some kind of resonance. I'm using 6/8/10mm end mills or slot drills. It's mainly side milling that gives the issues. The end of the sample aluminium base section I posted yesterday for example is about a 20mm deep x 10mm wide section, and when facing the ends to neaten it up, the cutter squealed like a pig no matter the speed, depth of cut, climb, not climd or whatever. I was trying to face it using the full depth of a 10mm end mill. Maybe it's just me I dunno. Fed up with it TBH, I just try to avoid it now.

When you say "throw away cutters", what do you mean by that? If you mean cheap, then I had some of those, and folks on here told me to buy premium stuff because the cheap ones were probably contributing to the issue.

I added an x-asis power drive (just a dc motor and speed control through a dog clutch) that reduces handle spinning on longer parts (and often gives me improved surface finish on wide surfaces).

Anyway, I'm currently finalising the materials list, and converting the drawings to metric, then I need to convert the ML7 to wide bed format to get rid of some wear, and add some slide bearings. Then I'm good to get on with machining again.

I'll just crash on with grinding some of the HSS tooling I've got, but never use, and see what happens on some test material.

I replied to this earlier but for some reason it has not posted. I'm having a lot of problems today with the computer dropping in and out of internet connection.

No, I definitely didn't mean 'cheap' cutters (never a good idea) but Jason has explained what I mean perfectly. Any good brand of FC3 cutters will be ideal. There are cheaper versions on Ebay but despite their attractiveness the quality of life rarely holds up.

Any mill that is exhibiting the kind of issue that you describe is definitely suffering from a lack of rigidity – somewhere – it's finding it that can be a problem. As Jason suggests I would certainly begin at the spindle and check for any slackness in the bearings first, both vertically and radially, then work out from there. Assuming the table axis's are firm and well supported squealing, chatter, juddering when cutting is usually a lack of firmness somewhere in the spindle set up or in it's guide in the head. Certainly worth spending some time on to improve it if possible – the machine should be able to be relied upon at the age it is.

A power drive is a very nice accessory to have – my Amadeal mill is still waiting for one, nearly six years after being told it would be a few months! The finer pitch leadscrew on that compared to my old Linley certainly makes for tired arms on lenghty parts!

Edited By Ramon Wilson on 25/10/2020 20:24:29

Dr_GMJN.