First thing is to bin the book.

Second thing is to repeat this mantra – feedrate, feedrate, feedrate

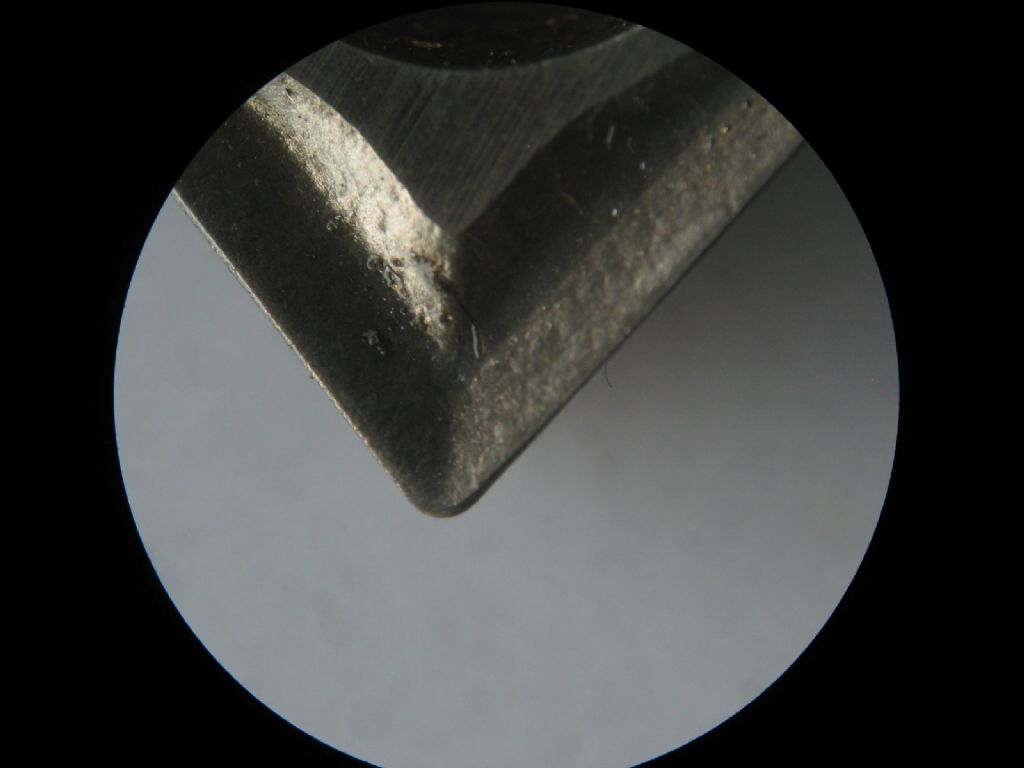

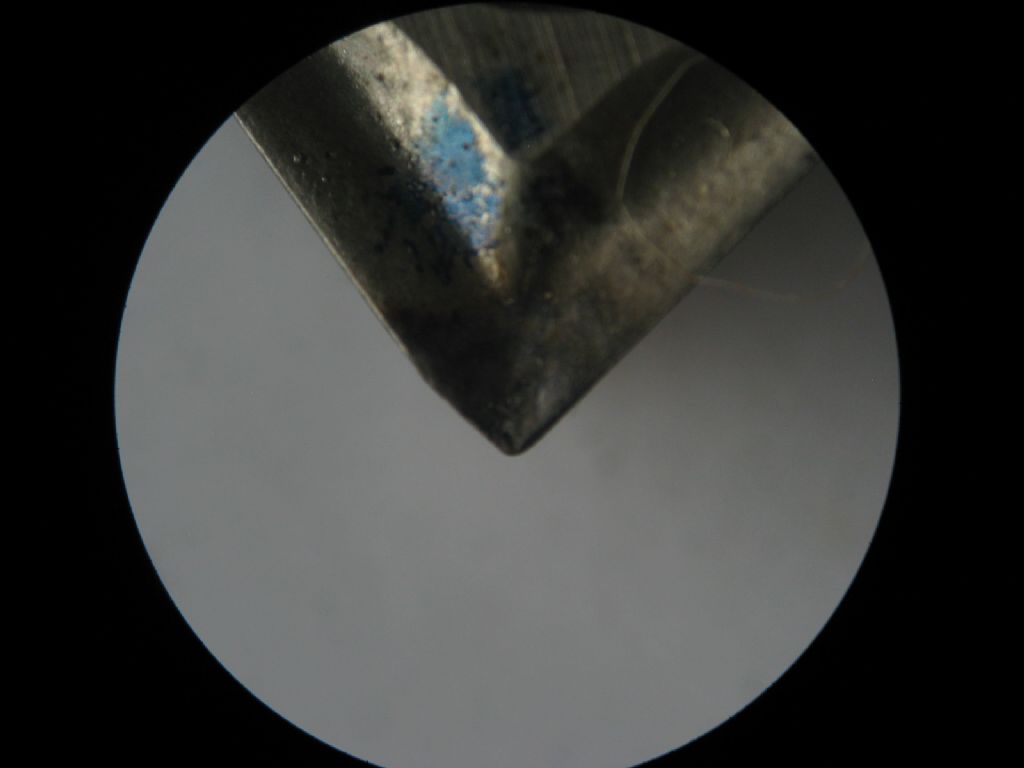

For 1" diameter steel I'd be running at 1200rpm. The DOC ideally needs to be more than the nose radius of of the insert, although that it does depend upon the material. For roughing I use 0.1" (0.2" off the diameter) which is convenient as it is one turn of the cross slide handle. Finishing cuts may be 20-40 thou depending upon how much material is left.

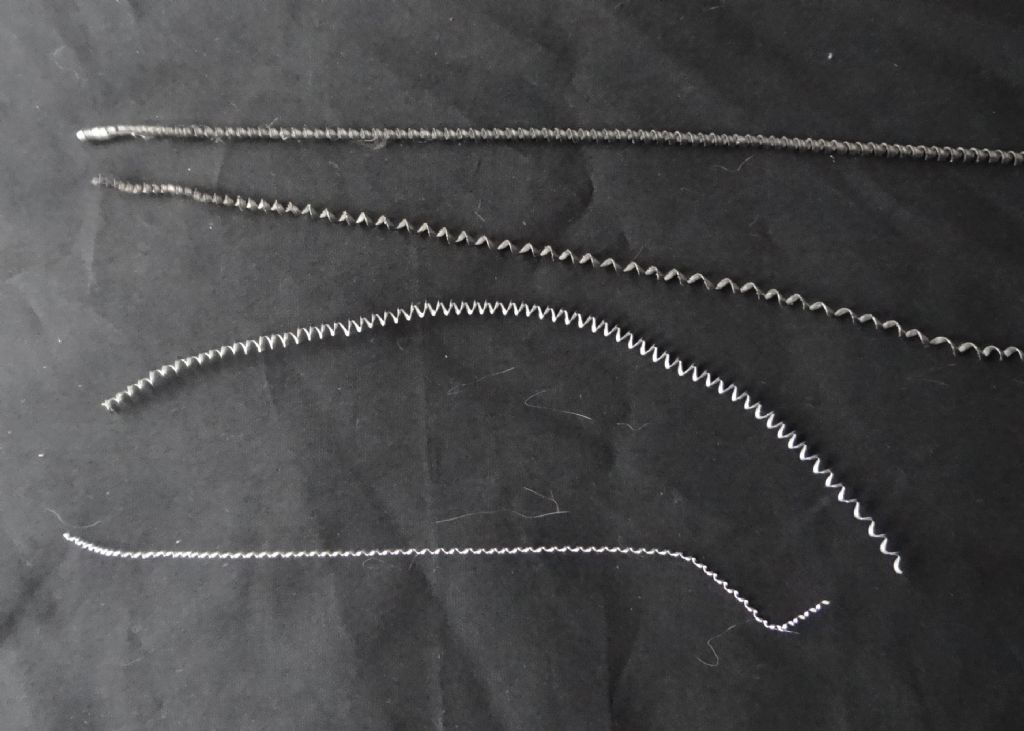

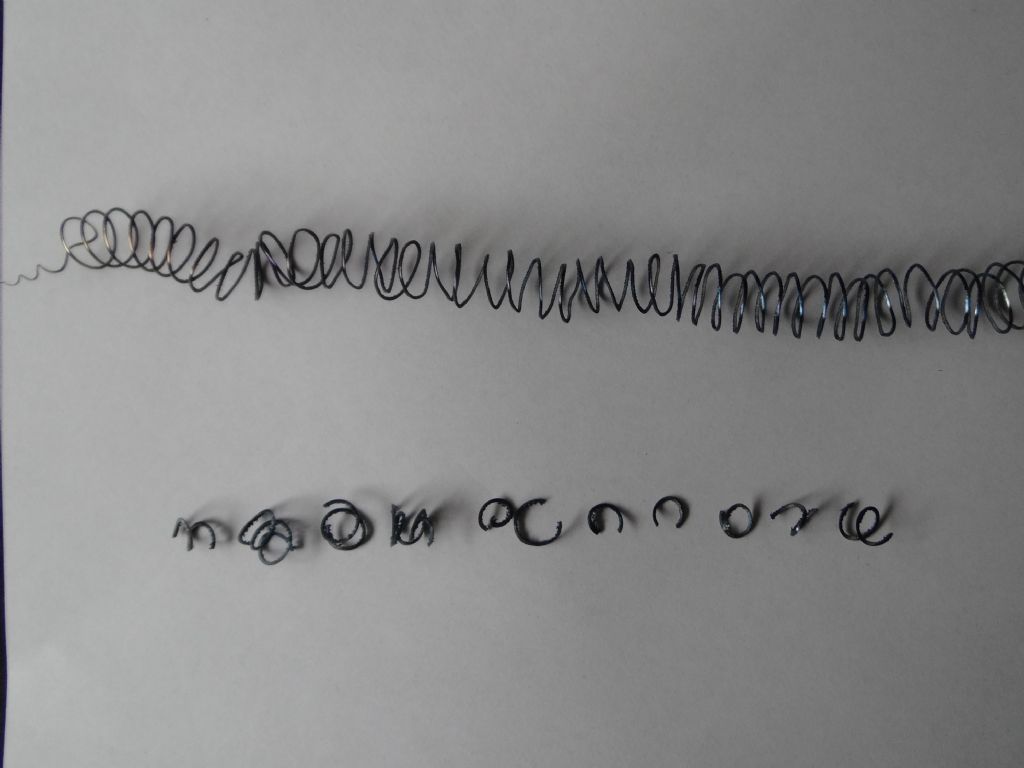

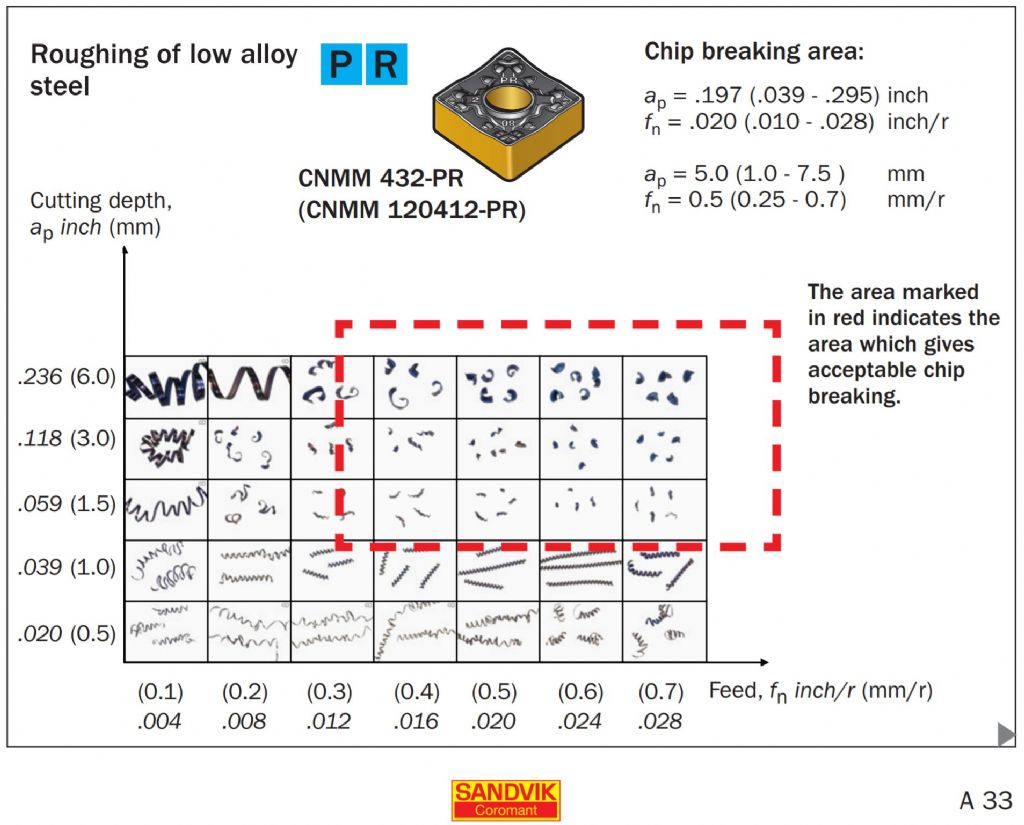

To get the insert chip breakers to work you need higher feedrates. For steel 4 thou per rev is about the minimum I use, but often 6 thou per rev for roughing. Aluminium seems to need higher feedrates, say 8-10 thou per rev, even with inserts designed for aluminium.

If you buy inserts in quantity they come in boxes with cutting details on the back. Here are some typical figures:

Korloy CCMT09T304 NC3220 for steel: DOC 0.30 to 3.00mm feedrate 0.08 to 0.23mm surface speed 150 to 350m/min

Korloy CCGT09T304 H01 for aluminium: DOC 0.10 to 5.00mm feedrate 0.02 to 0.30mm surface speed 100 to 200m/min

It's interesting that the minimum recommended DOC, feedrate and surface speeds are less for aluminium than for steel.

Andrew

Carl Wilson 4.