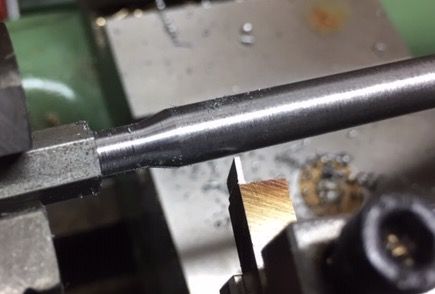

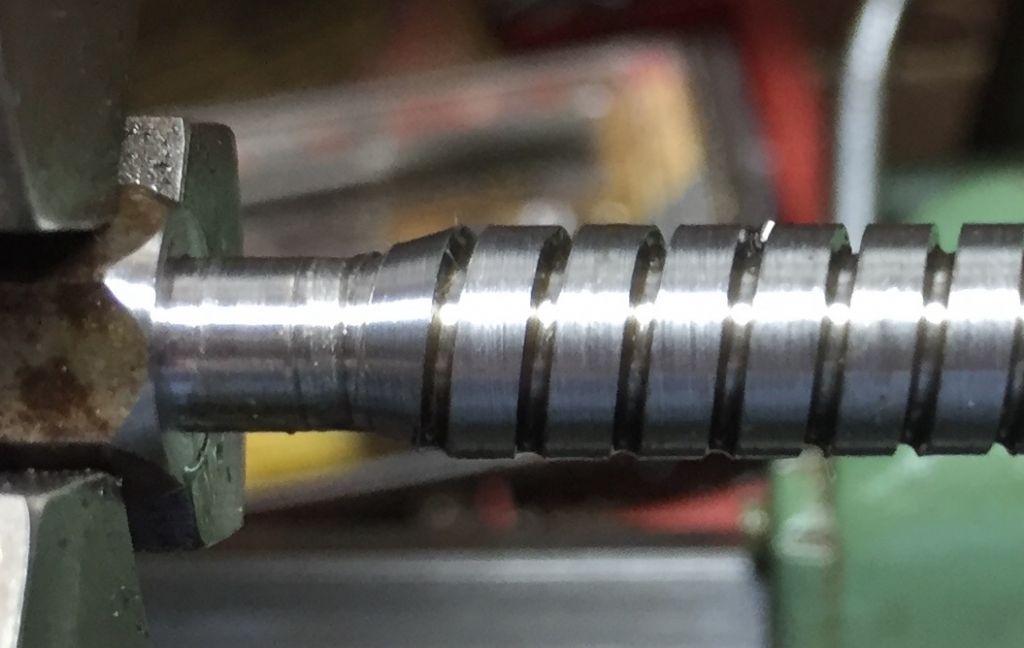

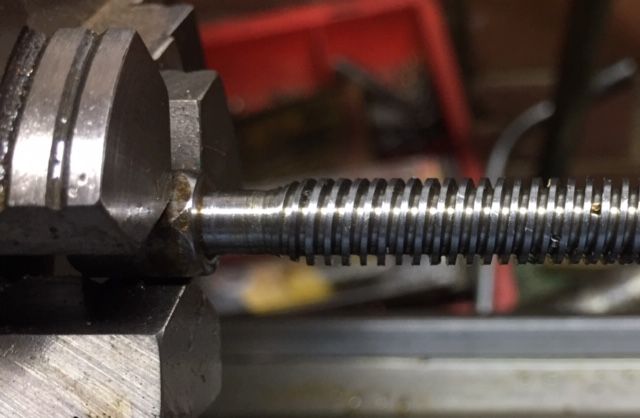

Since this thread has been running I have been making a mate a reverser screw for his locomotive. It is 5/16 diameter, two start square left hand. Each start was 8 tpi. The tool was about 1/32 wide. When I broke my cross drilled tool on the bms, I ground up a tool from 5/16 HSS tool blank, cutting out a block with the Dremel, and grinding to finish. Minimal side clearance for strength. Note that the toolpost is angled to the helix angles , which is quite a bit at 8 tpi. I switched to free machining steel, sacrificing hex, and put on modest cuts of 1-1/2 thou. Cut 40 thou deep. After the first start, I moved the top slide .0625 and cut the second thread.

The point is, it is very easy to grind up a tool for a job. Some model engineers, not necessarily the o.p., seem to be addicted to insert tooling. I wish they would grab a HSS blank and have a go at grinding a tool or two. They might be surprised how easy it is.

Anonymous.