Posted by BOB BLACKSHAW on 12/05/2020 10:47:41:

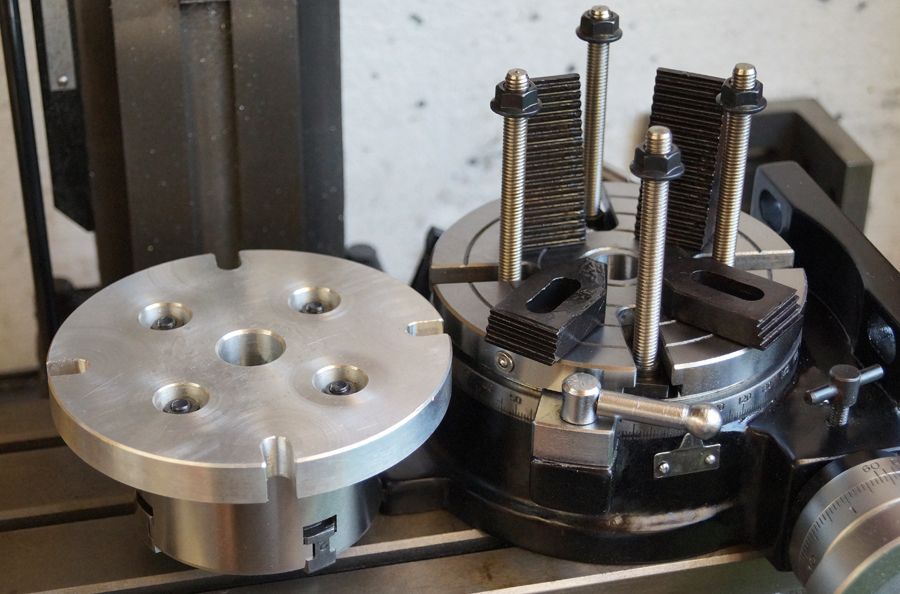

Question about the 5 inch Soba rotary table. My hand wheel seemed a bit slack so decided to adjust by instruction on the service manual. I have now got rid of the slack and feels better, but the grub screw on the side that's 90 deg to the worm lock tee screw what is this for. I screwed it in and lost the grub screw in the mechanism but luckily it was still held on to the allen key so I could unscrew it, but it doesn't seem to do anything. as its not shown or explained what its for. Also the instructions show a diagram with a screw A and B with a steel ball, I cant find a steel ball on my rotary table. Sorry if I'm a bit thick but if I'm show something I've got it but reading these instructions has got me confused, Why also is the clamping on the table can take 12mm bolt but give 8mm bolts there seems a lot of space I would of thought 8mm plus slots would have been better, and on the side of the rotary table there is not enough space for a 12mm nut if you wanted to have one as only enough room for half a nut, same with the tailstock slot to take 12mm. I understand that its cheap but with a bit of thought and no expense on manufacture it could of been made better.

Bob

Edited By BOB BLACKSHAW on 12/05/2020 10:59:14

I can only go by my table Bob but I think you have the same model as me.

If you measure the T slots on the table they are 10.8mm wide and the supplied T nuts have a threaded shoulder which is 10.3mm diameter so there is only 0.5mm overall clearance in the slot when the T nuts pull up on tightening, this also centres the M8 stud.

Also the steel ball you say is missing is between grub screw A and grub screw B and is a protector/lock for the inner screw B. Inner screw B adjust the mesh of the worm gear, so to adjust B you have to remove screw A and the ball, adjust and then refit ball and screw A. Its all shown in a diagram and there is an explanation of how to adjust.

p.s. If you screwed the grub screw A all the way through the hole then that would mean screw B and the steel ball are missing..?

Edited By Ron Laden on 12/05/2020 14:49:11

Sakura.