Posted by Mike Poole on 14/03/2019 11:42:22:

Stefan Gotteswinter has a few videos on YouTube of his teardown and improvements he made to his vertex table, much of it would apply to most rotary tables.

I am sure that John Stevenson who did quite a lot of work with converting rotary tables to use a stepper motor made some comments on Vertex lowering the specification over the years on their RT, maybe changing the supplier coincided with the spec changes.

Mike

Edited By Mike Poole on 14/03/2019 11:48:30

Hi Mike,

I saw Stefan's video. It has 'OPTIMUM' badge on it. I cannot be sure that it is a VERTEX table. Optimum uses Chinese Factory C for some of their supply. Factory C makes the VERTEX copy too. Sometimes, it is possible to copy an instruction manual, for universal use.

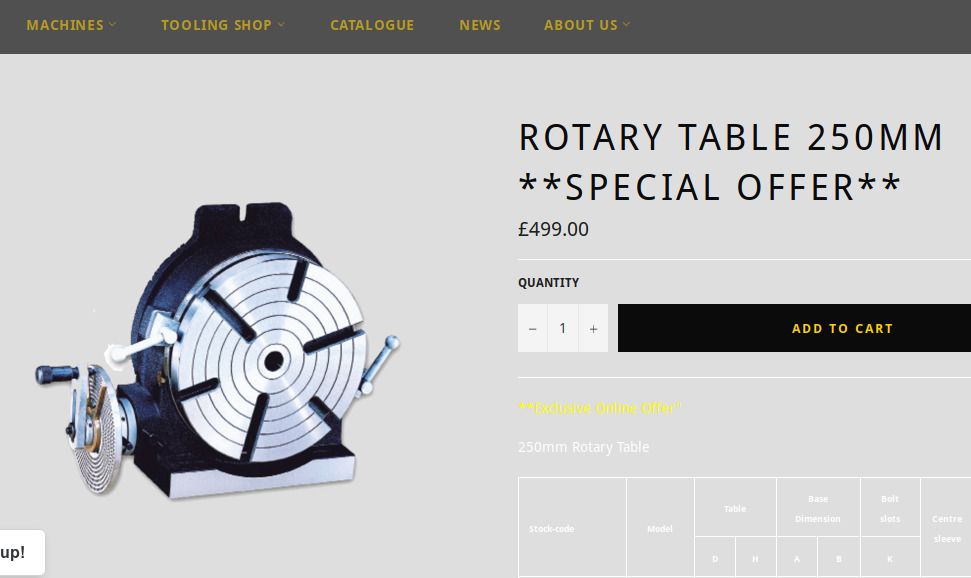

If you look at Stefan's video, you cannot see any drawn cup needle roller bearing (NRB) to support the worm assembly, where it enters the casting body. For most light to medium duty RT's this, along with other bearings are omitted. Over the years, the material from which the gear wheel? is made, has also changed. This applies to SIEG RTs from ARC too.

JS used to convert Vertex, ARC, various Chinese and Indian for use with stepper motors. Depending on application, he would check for presence of bearings. to the best of 'my memory' having seen this at Johns place, the old Vertexes had them inside the table, the newer ones didn't. He would strip all of these tables apart, finding good, bad or ugly. he would add bearings if and where necessary, or if a medium to heavier duty application was the purpose of use.

For SIEG RTs from ARC, they are fine for manual use. However, for use in CNC application, we do some modifications, and add some bearings inside the RTs, which makes them better for light to medium use, with much reduced backlash. Although we do not warrant them for business/commercial use, a high percentage of our sales are made to such users….. I guess due to price.

Coming back to VERTEX, I mentioned on page 2 of this thread, that they used to buy from FACTORY A in the past. FACTORY A has clarified to me that they did not buy this product from them. So I was wrong in making that statement, for which I apologise. That guessing goes on.

Thaiguzi mentioned that his VERTEX is around 25 years old – Made in Taiwan. May be it was – totally, or it was finished in Taiwan. I am now getting more and more confused about its origin. Now, all I can say is that VERTEX of old is different from VERTEX of new. In either case, the product does have some consistency in production, and most of the users are well happy with it…. be they with or without bearings.

Chinese Factory B offers the VERTEX copy – with or without bearings. So now I wonder if original VERTEX offered these with and without bearings in the old days or now.  . Its all clear as mud.

. Its all clear as mud.

Ketan at ARC

Sakura.