Ketan,

You have cheered me up, a lot. I was beginning to worry about my elderly Vertex HV6. Having always used mine in "Plug and play" mode, (Ignorance is bliss); began thinking "Should I have checked for, or noticed, any of these problems"? And then you came along and said that the old ones were probably made in a better factory than the more recent ones.

As in so many things, we tend to get what we pay for, you don't get a Rolls Royce for a Reliant price!

Really, the question becomes "Is it fit for purpose?, and "Is it value for money?" If the answer to both is "Yes" then end of discussion. Use it, subject to its known limitations. If the answer is "No" then action of some sort needs to be taken; either to modify / improve the object until the answer becomes "Yes" or to dispose of the thing, in a way which is controlled by your ethics and your budget. (Sell, "as seen", "faults declared", or in silence, or scrap. )

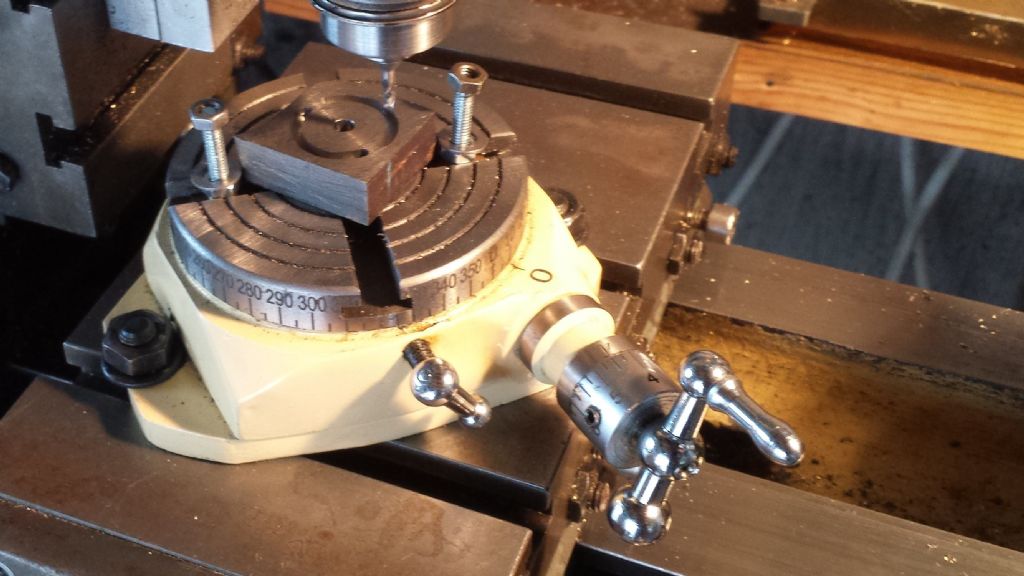

I use an elderly (from new ) RF25 Mill/Drill. It weighs about 150 Kg and does not have the features or rigidity of a 2 ton Cinncinatti vertical mill. I could not afford such a machine, or have the space for it, and would not use all its capabilities.

So, I make the best of what I can afford and can accomodate, recognising the limitations that are self imposed

Howard.

Edited By Howard Lewis on 12/03/2019 20:24:26

Sakura.