The original motor power is extremely limited on the wee unimat sl, belting is a big big issue as well. The motor usually needs resting every 10 minutes or so to prevent overheating.

(going back a bitty now)

I ended up removing the original motor and getting a 1450rpm off ebay, then getting some of that 4mm red belting and fixing the lot to a baseboard.

The difference was like night and day for lathe work, she actually made hot swarf!

The original motor was still needed for the drilling configuration though.

They are pretty amazing little units and highly versatile but quite limited for serious work because they really do lack stiffness, especially when that little weeny carriage is hanging out over thin air for a side cut, too much flexing.

If the ways/bars had been 16mm instead of 12mm this would have made a huge difference.

Watchmakers use units like Cowells lathes, which have a ‘proper’ bed and even have backgear.

If you do continue down the slow speed attachment route invest in some decent belting to transmit as much power as possible to the spindle for a decent cut.

Without decent belting you can’t do much work on a unimat sl.

David Costello.

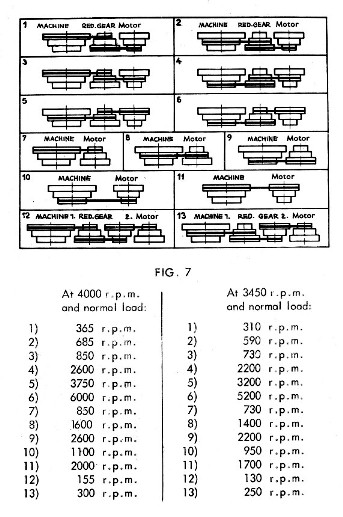

.yes ebay has a US seller but again a bit steep.I need to turn some 50mm od steel which the book tells me 350rpm,my slowest is 900rpm,so will try that first.

.yes ebay has a US seller but again a bit steep.I need to turn some 50mm od steel which the book tells me 350rpm,my slowest is 900rpm,so will try that first.