I was asked in another thread for some details of my vice stop, rather than loose it in that thread I will describe it here.

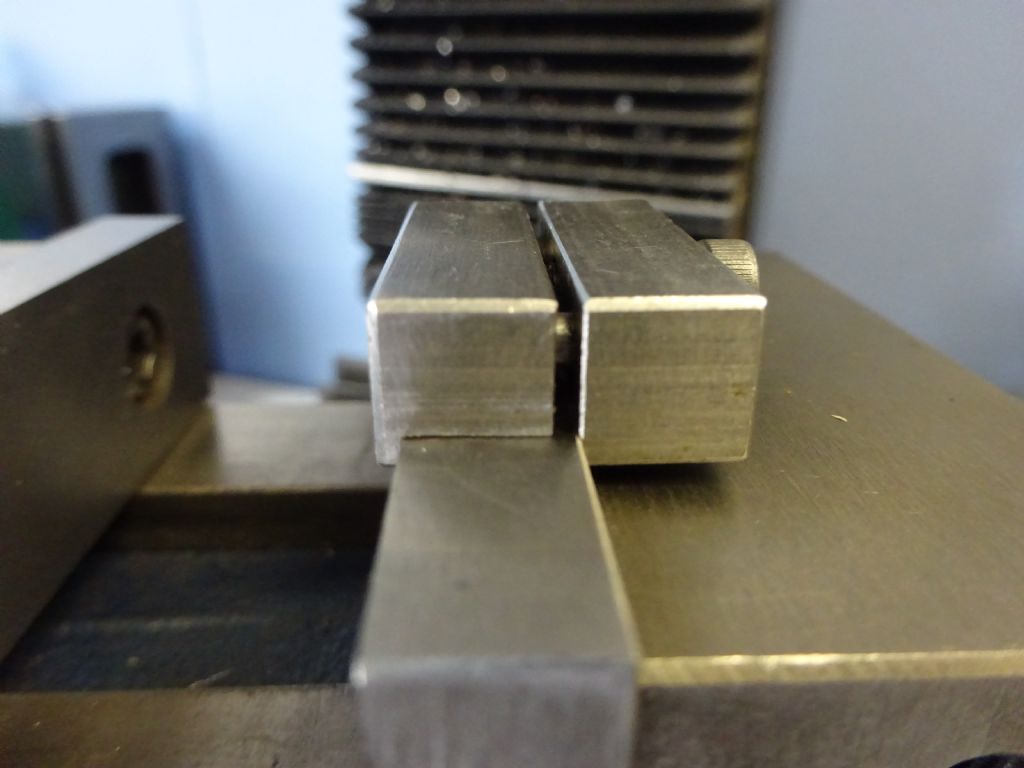

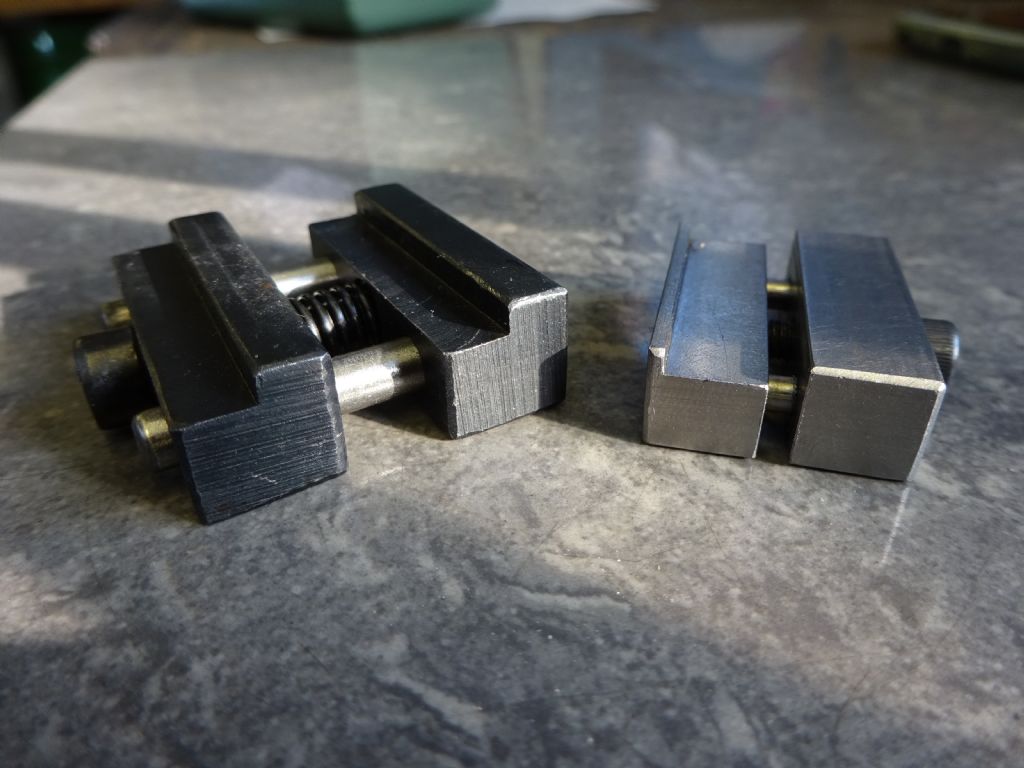

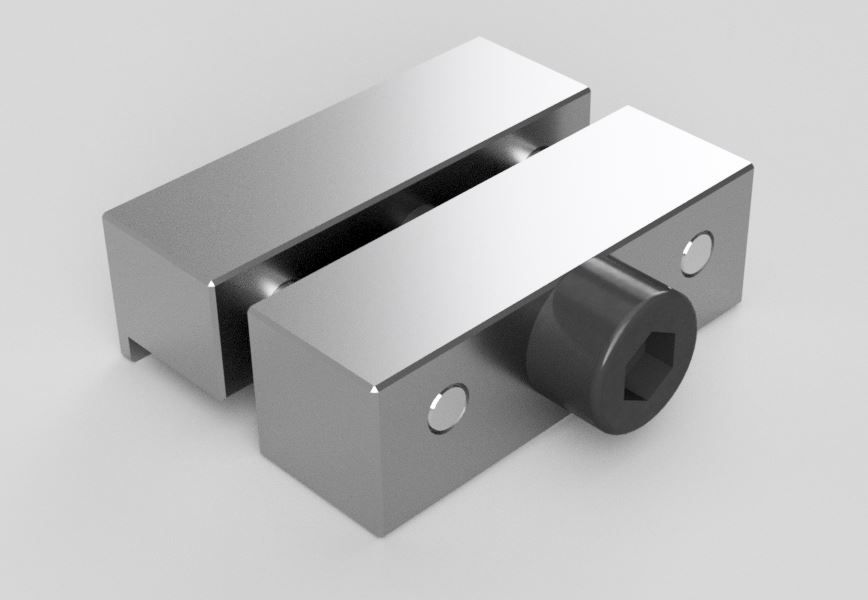

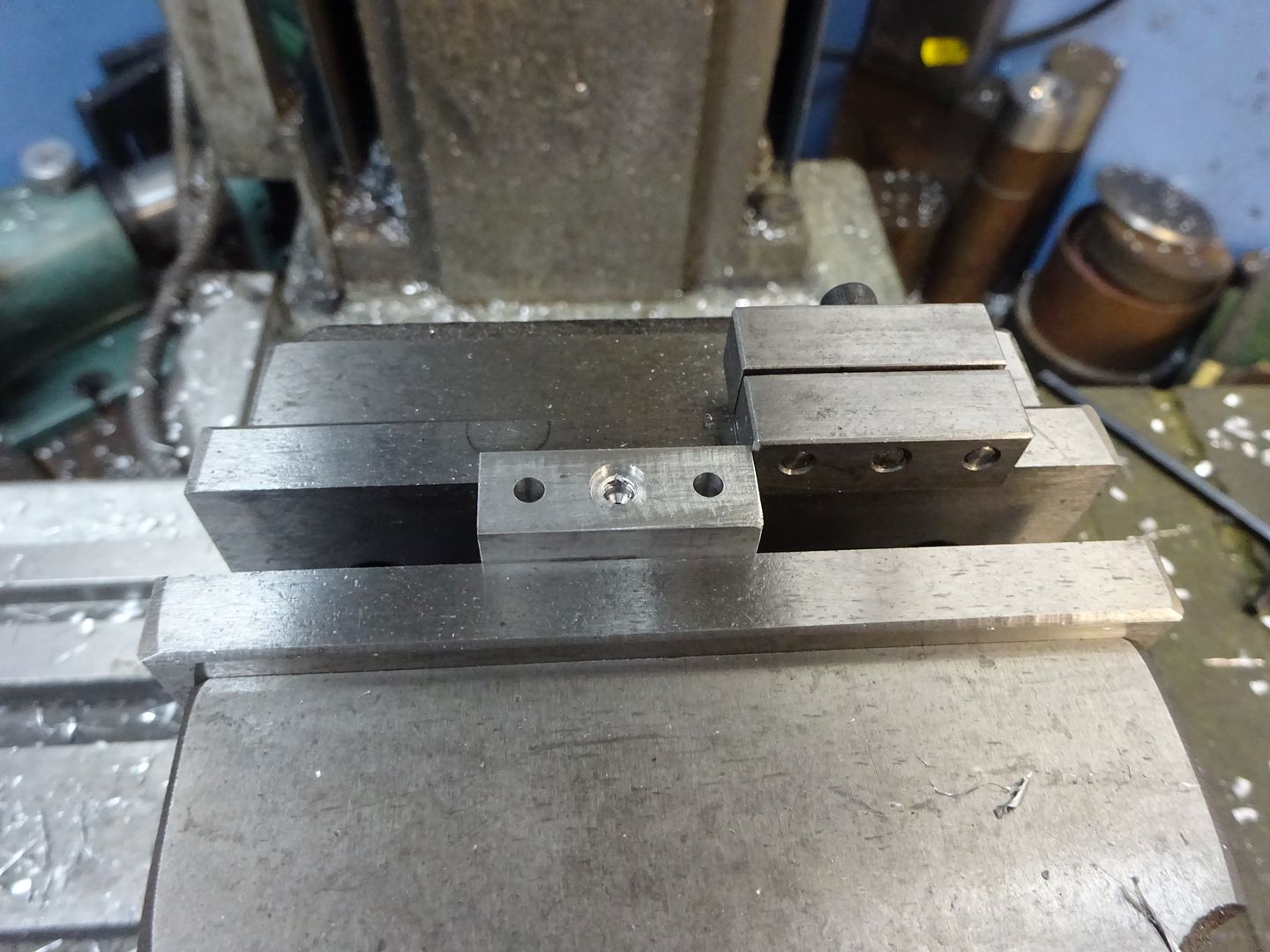

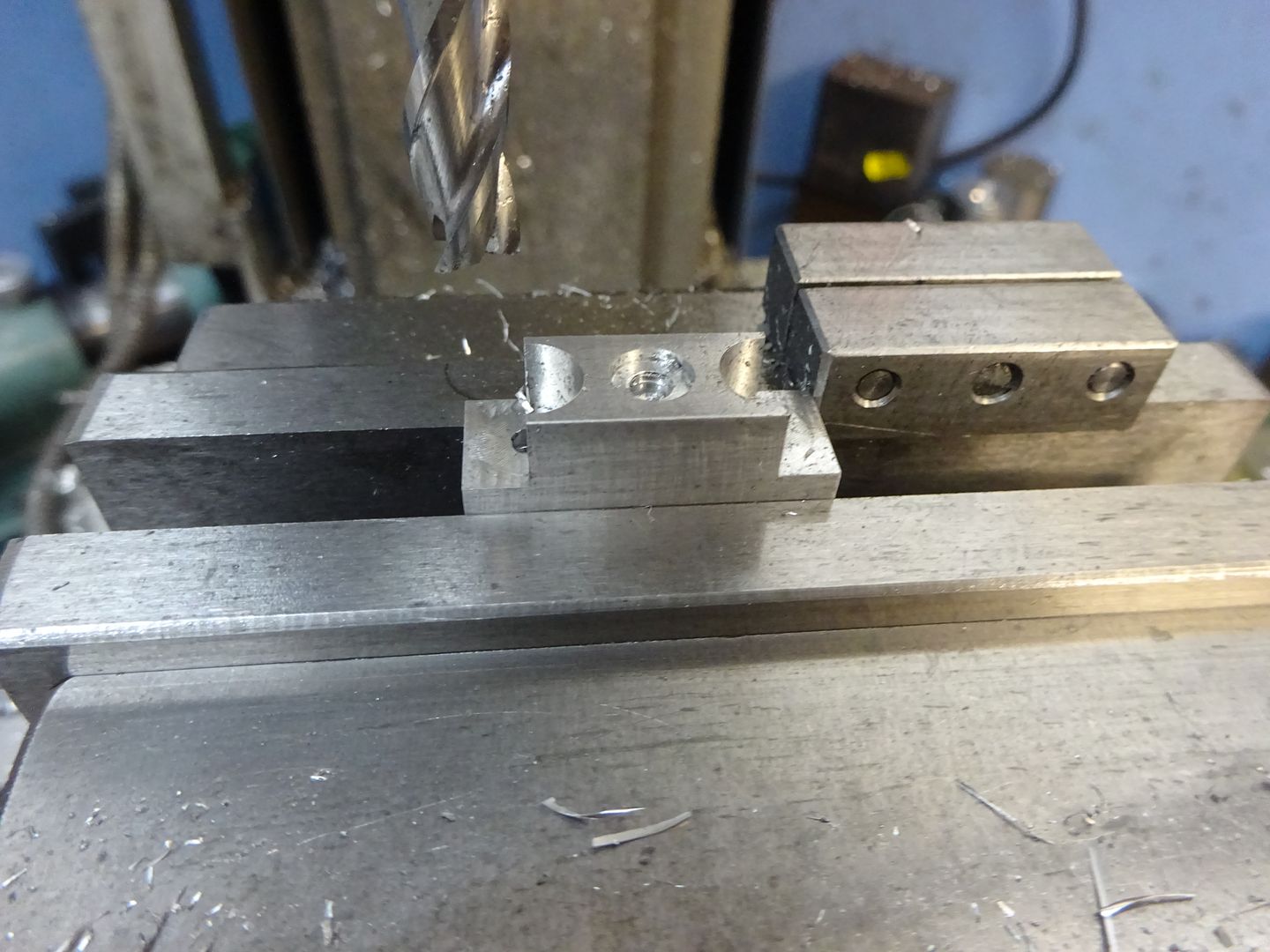

The two main parts of the stop are 30mm lengths of 10mm square bright mild steel, one of which has a notch milled into it leaving a small lip that hooks over the protruding edge of the vice jaw. The two halves are kept inline by two 3mm dia steel pins and a M4 cap head screw cloamps them onto the jaw.

What I like about this one is that the lip is quite narrow which allows the vice to grip work down to 1.5mm thickness, there are commercial ones about for those who would rather buy but they are a bit thick, at least for some of the small work I tend to do.

Construction is quite simple the 3mm holes are reamed all the way through the block with the lip but only part way through the other block, this gives a nice press fit as the rods are pushed into the tapering hole left by the end of a hand reamer. It would also be OK to just drill the holes and use something like Loctite 638 to retain the rods in one half.

The central hold of the lipped block is tapped M4 and a clearance hole drilled in the other half for a M4 cap screw.

If you prefer in metric then 3/8" square stock can be used together with 1/8" pins and 2BA screw.

Drawing To Download

J

old mart.