If your cross slide arrangement and / or topside mounting system don't suit the simple version it ought to be possible to come up with some sort of intermediate "plate" device to carry a suitable pivot onto which the topside could be bolted. Tool height may well be an issue. On smaller machines you'd probably need some sort of drop mount carrying a small toolbit in front of the slide. Tangential type might well be better / easier than conventional.

That sort of arrangement can be thought of as a more sophisticated version of the device described by Edgar Westbury writing as "Ned" in Model Engineer volume 100, p 582 et. seq. A 1949 issue but I don't have the exact date. Geo. H Thomas writes approvingly of its simplicity but, like me, doesn't care for it swivelling directly on the cross slide with the inevitable turning debris interfering with smooth motion. Also on older, well used machinery the flatness of the cross slide top may well be less than would ideally be desired.

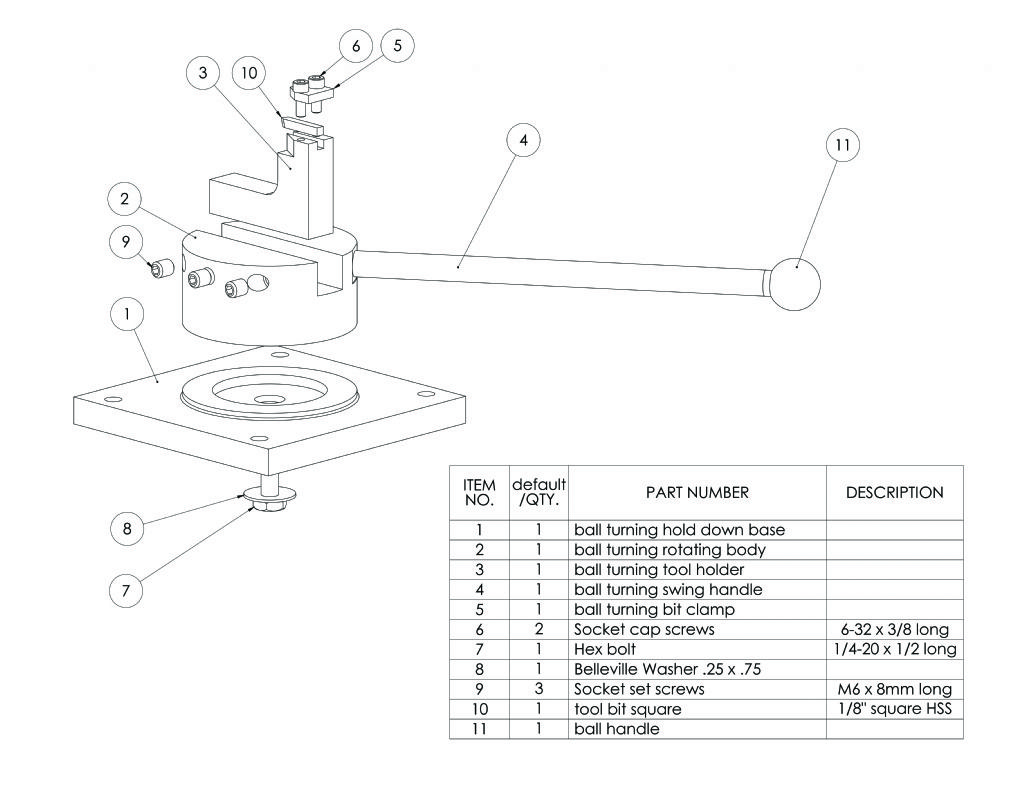

George added a baseplate to take the rubbing and also provided a simple slot in which the toolholder slides for easier tool position adjustment when setting the radius of the sphere. Ned simply advised adjusting the projection of the tool from its fixed holder. Using the topslide for tool carrying and adjustment is clearly even better. Arguably less work too.

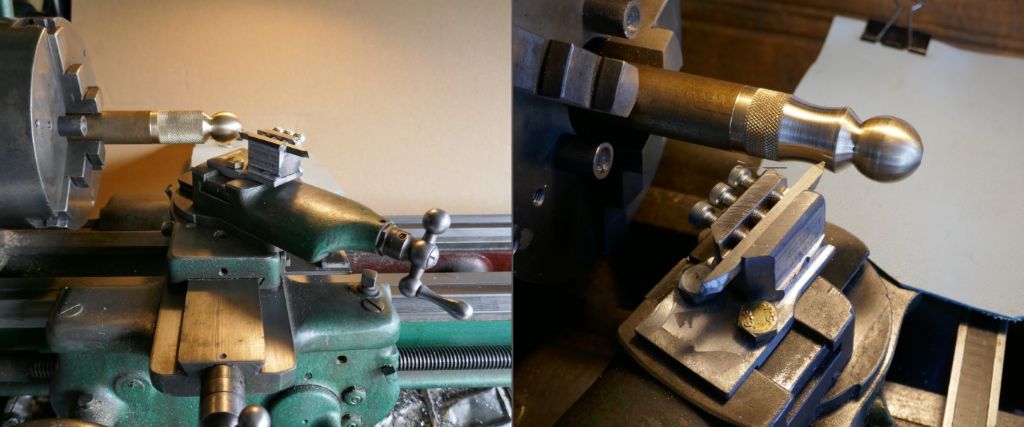

My own ball turner is a boring head based up'n over type. Effective enough and looks the professional part but objectively I'm unconvinced that the game was worth the candle when balancing the work needed to make it against the use it gets.

Clive.

JasonB.

JasonB.

swing industrial machine is perhaps another matter.

swing industrial machine is perhaps another matter.