There is definitely a bit of an art to silver soldering.

Using a good flux is critical, as is cleaning the metal before applying the flux.

I have only silver soldered a few items, but all were successful.

I have done a lot of soft soldering, and so the technique is the same, but with a lot more heat.

The art is to get the metal hot enough without burning up all the flux.

You have to get the overall part pretty hot, and then focus on one joint at a time to bring it up to the wicking temperature. There is a certain sweeping motion required to spread the heat a bit on the joint. You don't want to create a hot spot on the joint that will overheat the flux.

It takes a very surprising amount of heat to get the metal up to the temperature where the silver solder will wick, and for that reason I don't like to silver solder things, just because refilling the oxygen and acetylene bottles is expensive.

I generally use a shaded welding goggle when silver soldering due to the brightness.

If you are not seeing a wicking action starting on the surface, then the metal is not hot enough. Don't feed in the silver solder if the wicking action has not started, else you get the cold blobs.

Without a clean joint and good flux, and sufficient heat, there is no wicking, but rather just blobbing on the surface, which has very little strength.

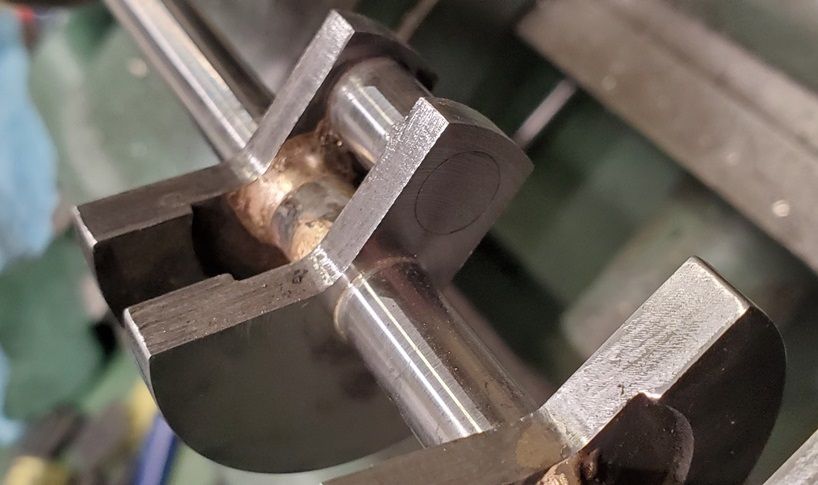

The strength in a silver solder joint relies upon having a thin joint, and a completely wicked joint.

Thick silver solder joints are not nearly as strong as thin ones.

I am no silver solder expert by any means, but I can successfully solder with that material.

Too much clearance and the joint is not as strong as it could be.

Too little clearance and the joint may not wick.

I have seen some folks cut a step on the end of the pins, which they fill with silver solder.

A step would work, but a longer thin step would be stronger.

Pinning the crank will take the solder joint out of shear, so the solder is basically to keep things from moving, and not so much for strength.

And keep in mind that many motorcycle crankshafts are pressed together without any soldering or pins, so from that respect, I would say the pins are probably not necessary.

Certainly on a model engine operating under no load, the stress on the crank would be very minimal, and silver solder alone is probably overkill.

For a launch engine operated for a considerable amount of time under full load, you would have to pay much more attention to the crankshaft.

.

Edited By PatJ on 26/02/2021 16:05:11

Edited By PatJ on 26/02/2021 16:06:50

Edited By PatJ on 26/02/2021 16:07:40

Edited By PatJ on 26/02/2021 16:09:33

Edited By PatJ on 26/02/2021 16:11:02

Keith Hale.