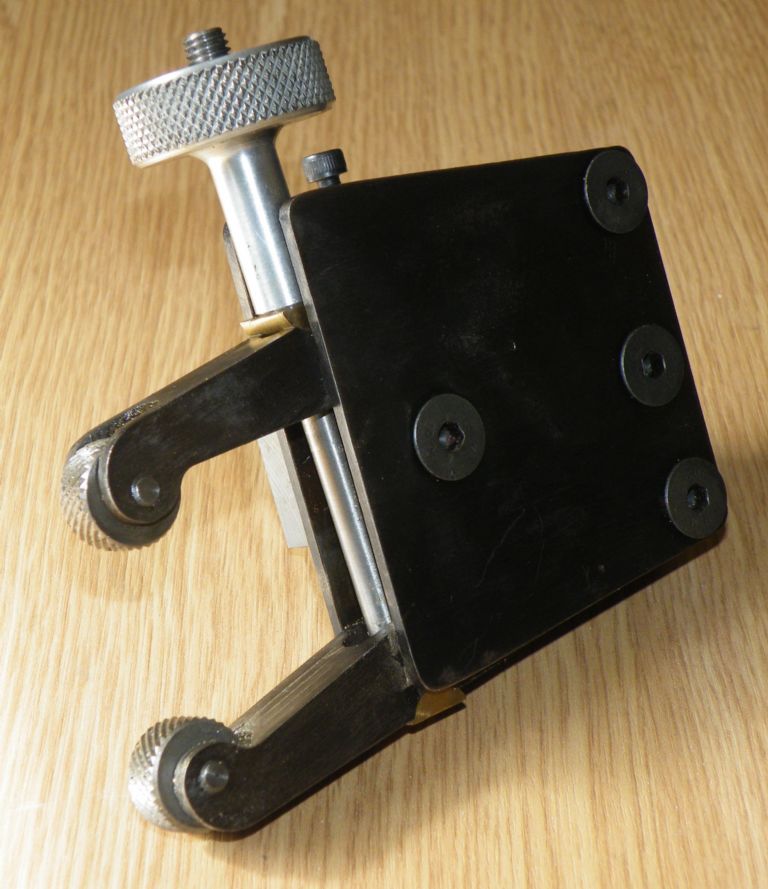

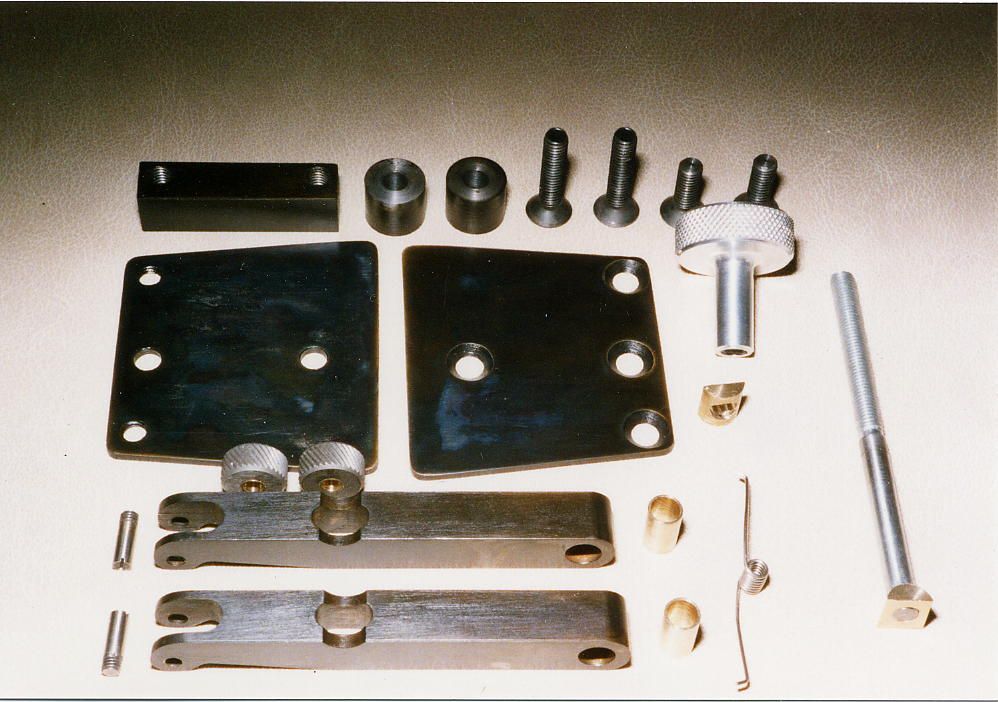

Shop made Knurling Tool

Shop made Knurling Tool

- This topic has 24 replies, 12 voices, and was last updated 22 November 2015 at 09:54 by

Ian S C.

Viewing 25 posts - 1 through 25 (of 25 total)

Viewing 25 posts - 1 through 25 (of 25 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Help recommend a milling machine?

- Traditional fly press uses

- Transwave converter – plugged in motor, tripped RCD

- What is this Colchester accessory used for?

- Bridgeport ways and wear

- What a flipping cheek !

- Suspicious Post? (Letters)

- Help Wire 3 Phase 2 Speed Motor

- Unusual lathe chuck

- Mary beam engine

Very limited files types only.

Very limited files types only.