Daniel

The 140 is a lovely lathe – well done getting it. I hope you have got the tailstock as well and the big 4-jaw chuck that the school might have had. The 140 was Harrison's later, metric version of the LS5.

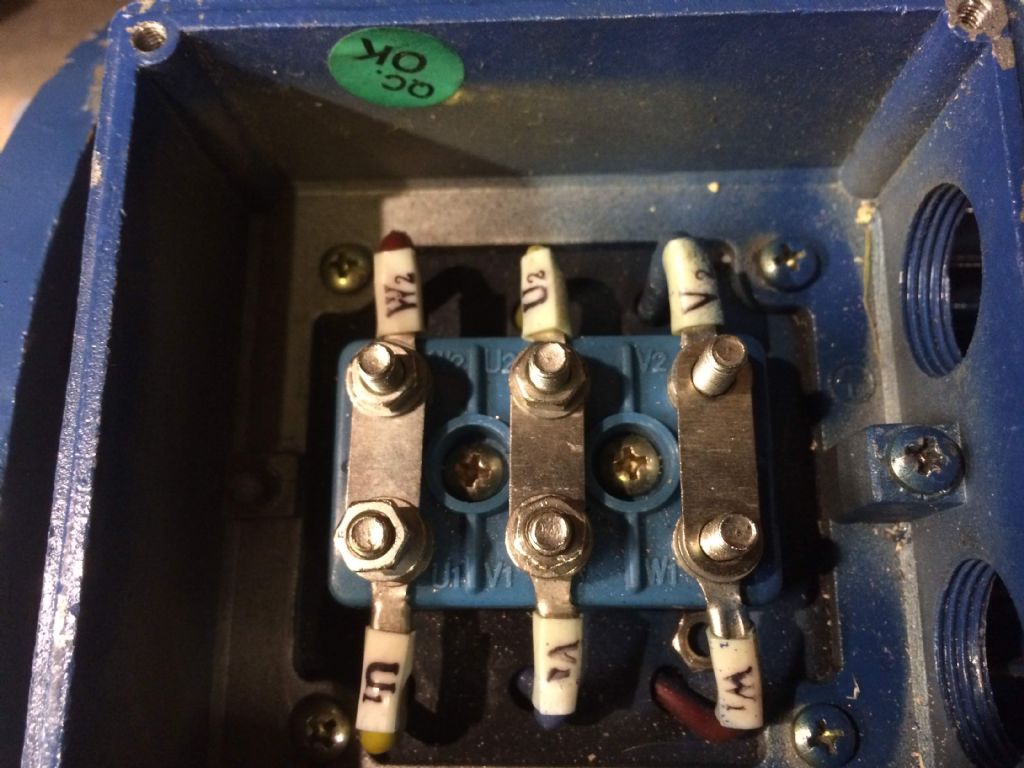

I fitted a metric shaft 1.5kw 240c 3 phase motor to mine. I just cannot remember if I had to modify the pulley bore. I have feeling it went straight on the new motor. The motor fitted the existing lathe frame with just some 2" sleeves and longer bolts to raise the motor. This all suggests that Harrison had fitted a modern spec motor. Measure your existing motor's shaft diameter.

I went to Newton Tesla and bought the motor, Mitsubishi VFD and a dongle controller together. It will cost you bit more than shopping around on eBay but you will have a nice system with start/stop, forward/reverse, jog/run and speed all on the controller in front of you. If budget is an issue then go it alone but you need to be confident in your abilities in programming and handling hefty voltage wiring. You MUST NOT start/stop the motor by breaking the supply into or out of the VFD. Wire the VFD directly to the motor and do not use any of the Harrison control switches.

I actually fitted a 2-pole motor (rather that the usual 4-pole) as it gives me the possibility of double the usual lathe speed. The 140s were built for it and you can get front plates that show the doubled gearbox RPM. To be honest I rarely use the higher speed, but I do run the lathe a half motor speed most all of the time and it is much quieter. The motor is perfectly happy for the usual light and moderate load jobs.

You can get some extra change wheels and will be able to cut all the imperial threads directly from that metric gearbox.

Edited By norm norton on 10/11/2018 11:22:31

Emgee.