Hi all,

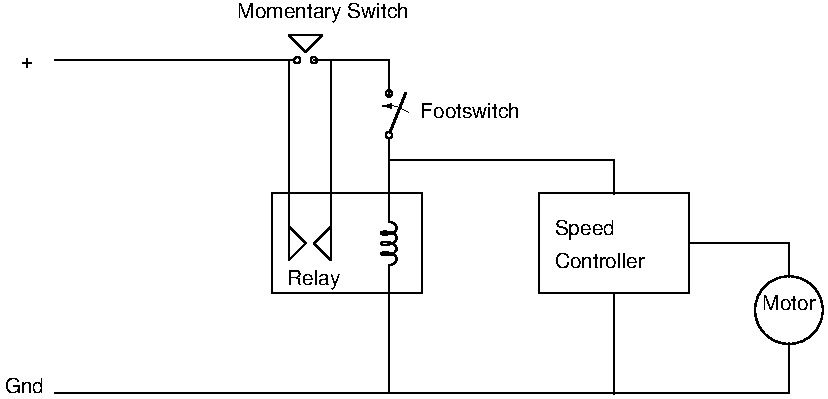

I wonder if someone with a bit of electrical know how can help. I have my lathe working using a 36v DC motor, which connects to our central solar system. My usual system for any machine in the workshop is as follows:

Central workshop switch panel: Switch that activates the relay, providing power to the machine

Then at the machine itself:

On/off switch on the speed controller

Foot switch on the speed controller

Both of these are on the power feed going to the potentiometer

In other words, once it's on at the wall, you need to have the switch on on the machine and then press the foot switch for the machine to come on (likewise to turn it off just take your foot off the pedal).

So far, so good. However, I noticed today that for one reason or another there is less room for the foot switch at the lathe and, despite my best intentions, every time I stopped and fiddled with the lathe, I forgot to turn it off at the switch. This means that if I accidentally stood on the foot switch the lathe would come on. No I have it set to accelerate very slowly, so not the end of the world, but that's not the point.

So I would like to add a circuit/relay into the system that allows the following:

Turn on the on/off switch – activate potentiometer circuit

Turn on the foot switch – turn on lathe (by completing potentiometer circuit)

Turn off the foot switch – turn off lathe and deactivate potentiometer circuit

The circuit should not then turn on again until the on/off switch has been set to Off and then On (i.e. pressing foot switch shouldn't bring on the lathe)

I realise many will see such a system as being OTT, but I guess we are each responsible for our own safety and being a little absent minded I would rather have one feature too many, than one too less.

Has anyone got any suggestions on how to do the above??

Many thanks,

James

Ian S C.