Sometimes one needs to do a bit of very small milling work and although I have a small, Chinese vertical mill as well as the Myford vertical slide which can be mounted on my little ML 10, neither of these tools will run at the high speeds necessary for very tiny milling cutters, drills or burrs.

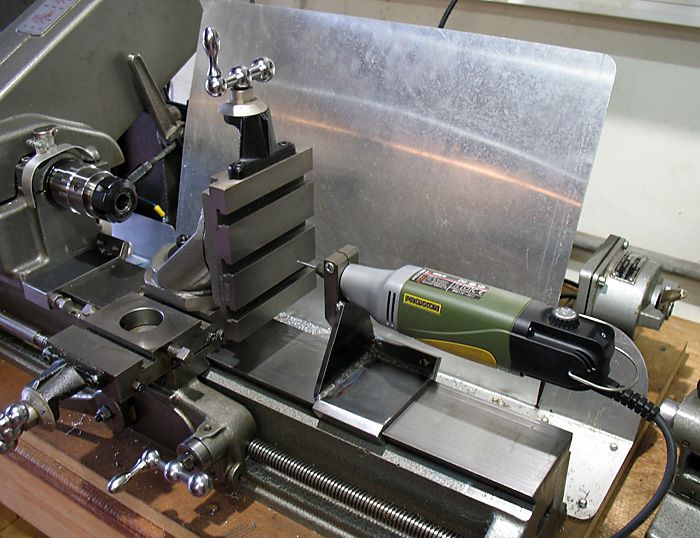

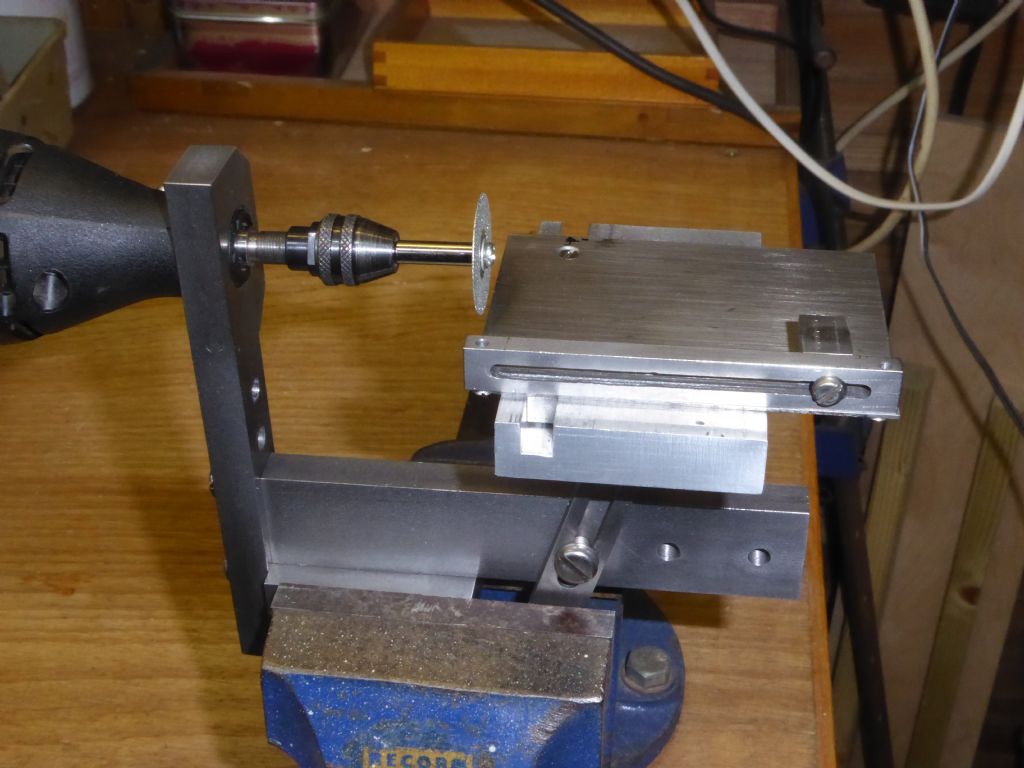

To give myself yet another bit of flexibility in the shop I put together a little support unit that allows me to mount my Proxxon rotary tool onto the bed of the ML 10 metal lathe. With the vertical slide mounted on the back side of the carriage I now have a tiny milling setup that permits me to tackle some of the smaller tasks.

I’m certain that this idea isn’t at all new, but I’m posting these images in the hopes that they may prove inspirational for others.

The design of any such mount will have to be altered to suit whatever lathe and/or rotary tool you have at hand. The only construction details of note are relative to the way I constructed this support unit.

Having a TIG welder in the shop, I chose for a combination of mostly milling and welding, jumping from one discipline to the other as required.

You will note a little centering ‘mandrel’ that I turned out of aluminum rod held in my ER25 collet chuck which allowed me to center the Proxxon rotary tool clamp more-or-less on the centerline of the lathe. This tool clamp was TIG spot welded to the support in situ, the rest of the welding being finished away from the lathe. Whether the rotary tool really needed to be ‘on center’ is doubtful, but this arrangement did help assure that the rotary tool's shaft was in line with the bed of the lathe.

Ignatz.