Hi,

I have been away for a week (driving a full size Fowler traction engine. Someone has to do it !!) and have just read your comments. Thanks for the feedback.

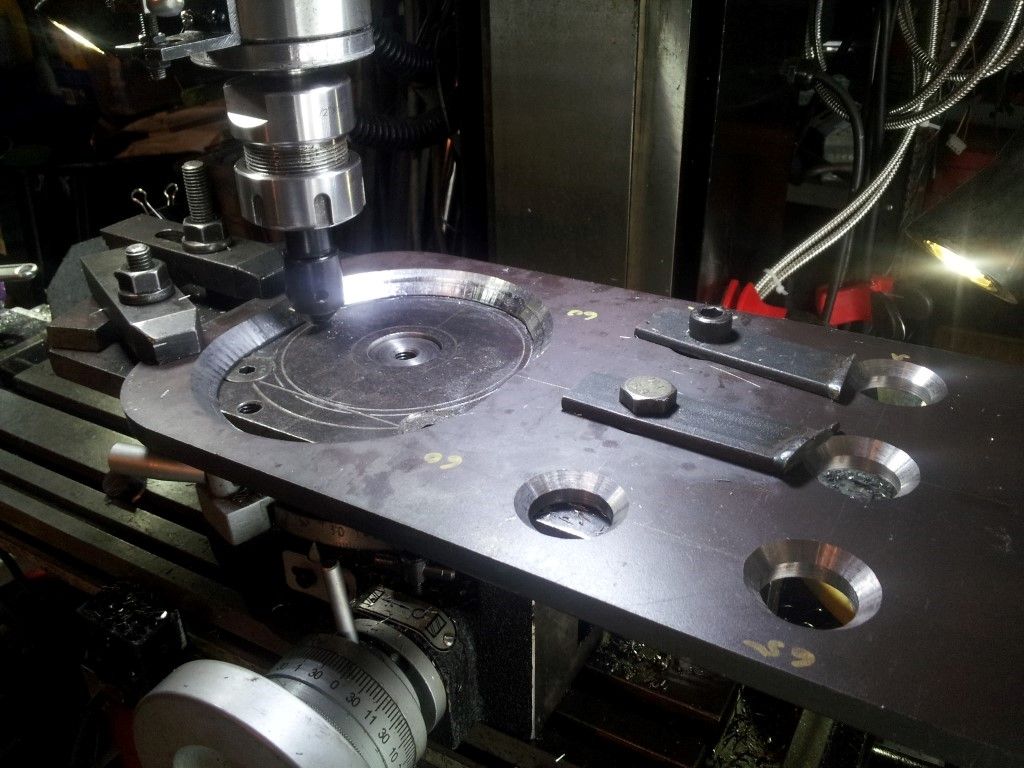

I have a 6" Yuasa rotary table and the worm gear has 90 teeth. It was lubricated with grease but was cleaned prior to taking the photo. The data sheet below states that it is suitable for circular cutting.

This is one of the responses from Yuasa USA :-

" Because this manual was translated from Japanese to English so when they say: High Precision Rotary Table is widely used for circular cutting work, angle setting, boring, spot-facing and similar work in conjunction with a milling machine.

What they mean by in conjunction with a milling machine is that you can put this table on a milling machine to hold you part and the milling machine makes the circular cuts and such. It doesn't mean the table can make circular cuts to make circular cuts with a milling machine you would lock your part to table then clamp table with the 2 brake shoes so table doesn't move and the milling machine would make the circular cuts on your part while you part and rotary table are stationary not moving. it doesn't mean milling machine just stays stationary cutting while you turn rotary table ".

And also from Yuasa :- "Its the same thing on page 4 of the manual says can do center cuts in conjunction with a tailstock. this doesn't mean the tailstock makes the center cuts it just holds you part center so you can make center cuts with lets say a mill or something ".

???? How else do you make a curved cut on a standard mill without turning the RTable ????

Paul.

Paul Lousick.