You would need to be threading very near to the chuck to be in any danger of running into it,no thread goes right up to the chuck.

I leave the leadscrew/halfnuts engaged all the time,while threading,using the angled top slide to set the dept and the cross slide to put on the cut. When you reach the end of your cut,wind out the cross slide and reverse the lathe back to the starting point,while bringing in the top slide a bit deeper. You get into the habit of using both of them together,and it works a dream.

Sparey was using this approach back in his day,and it still works.

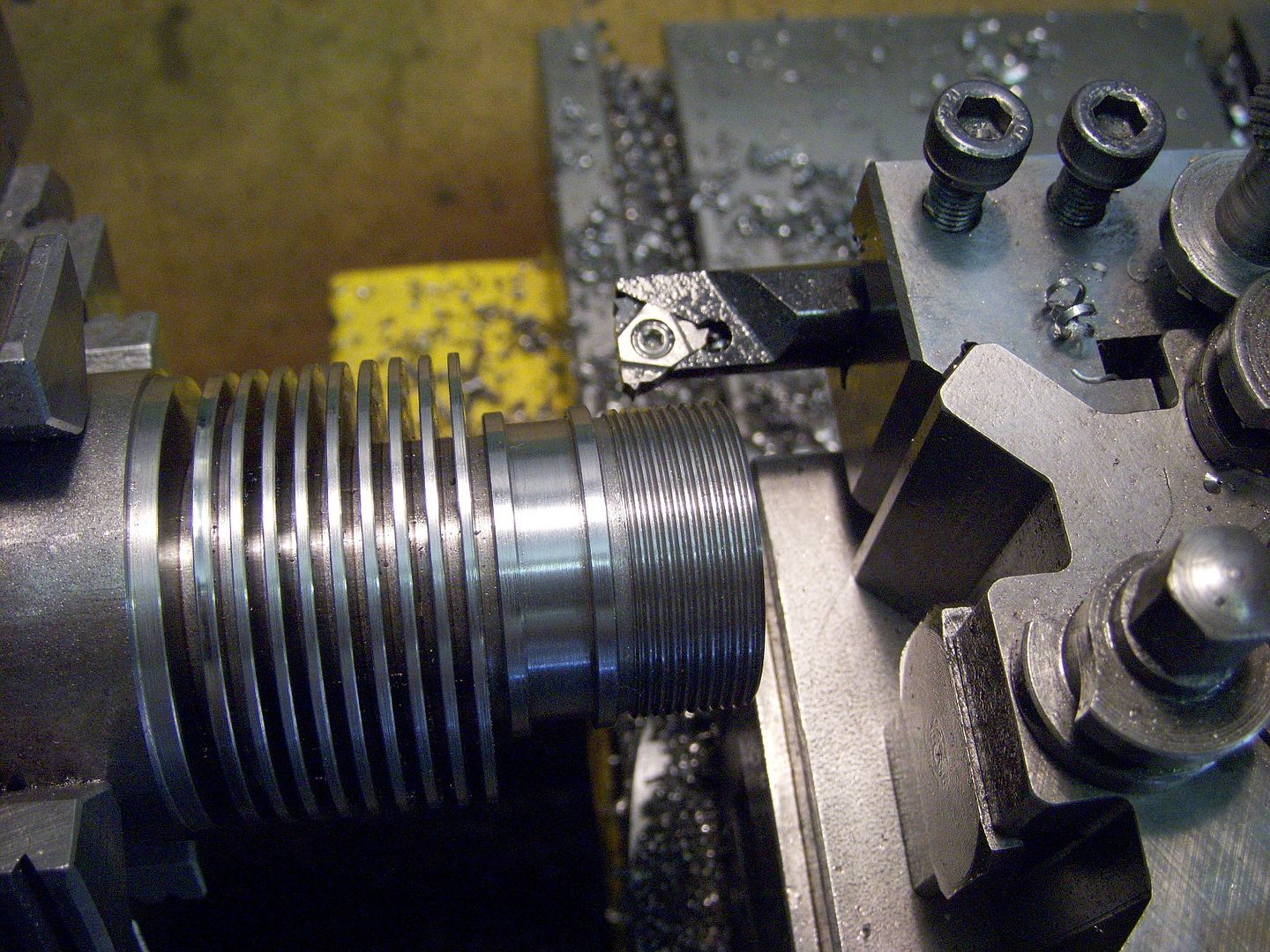

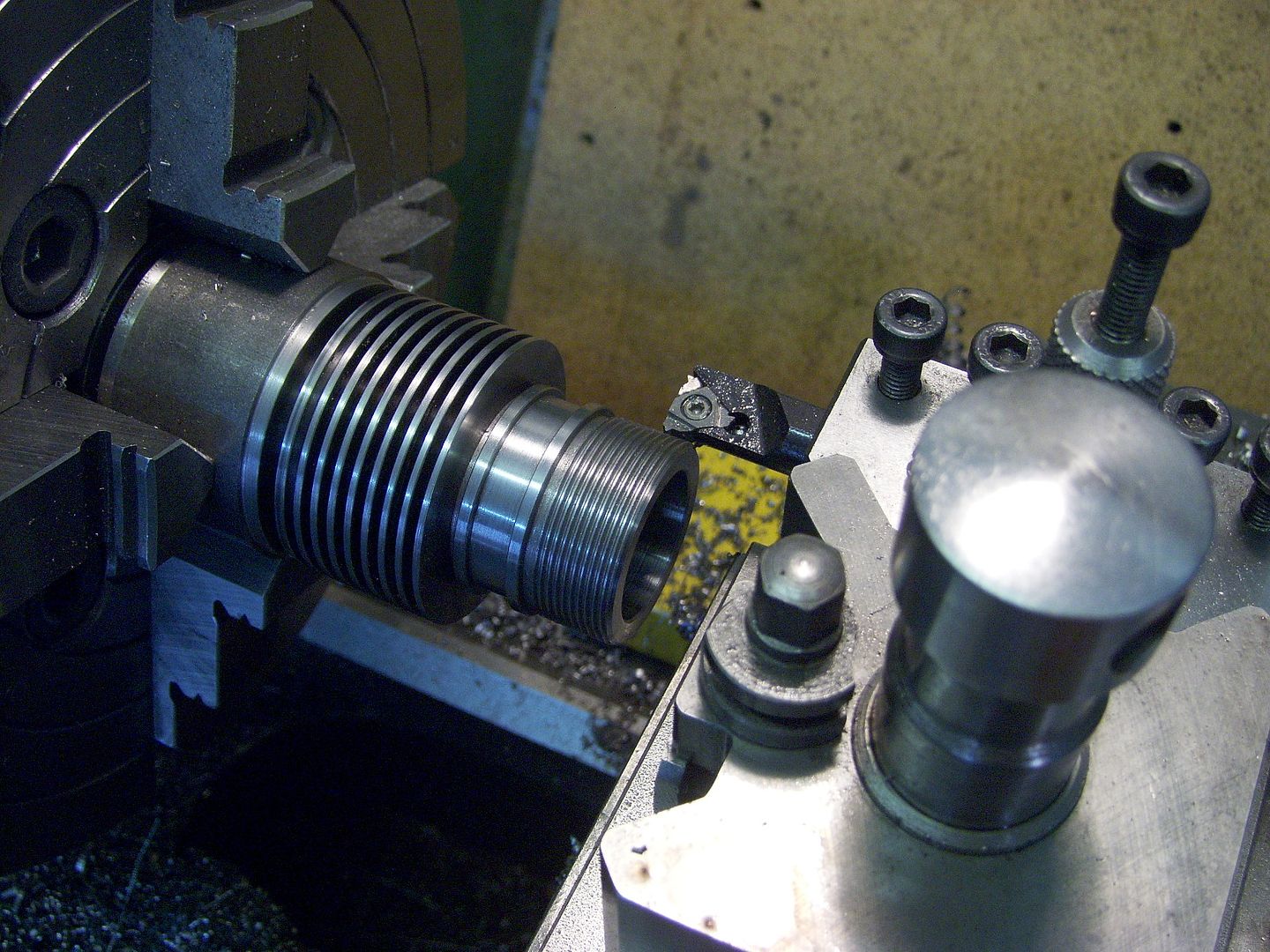

The only time I have to watch it,is when I,m cutting large threads like 21/4"x 8 as on my lathe spindle,since the carrage is really moving and while I might not hit the chuck,I could run out of road,so to speak. Result is much the same. Chips might not be blue but the air sure is !

Lathes do not like things like that.

mechman48.