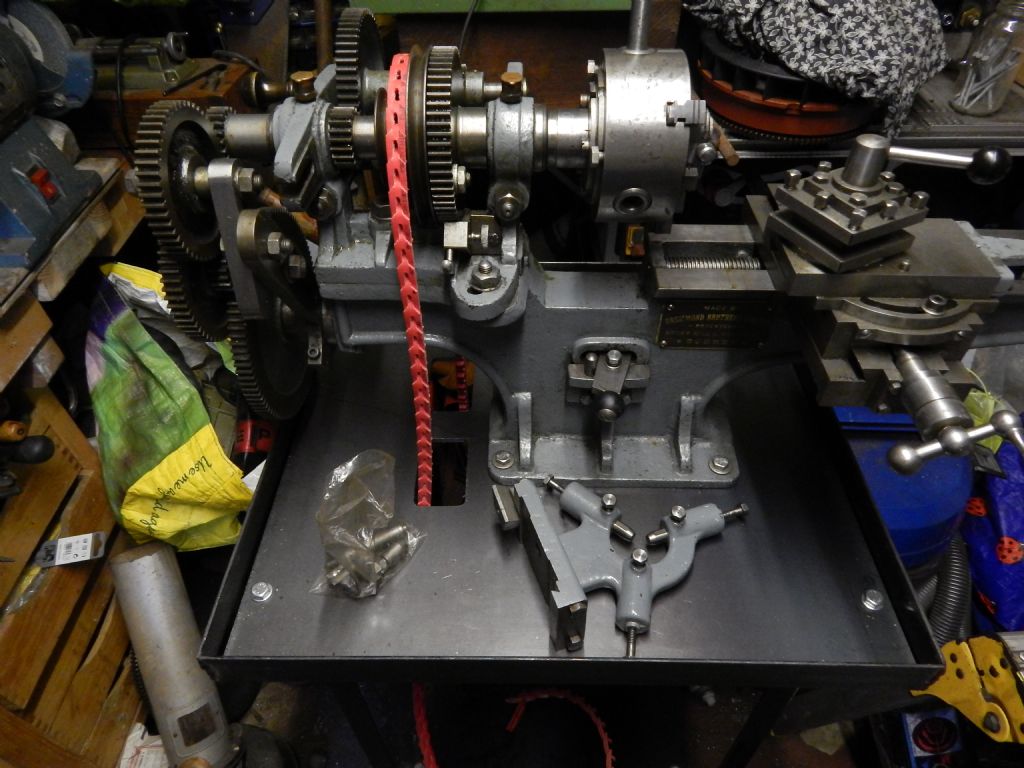

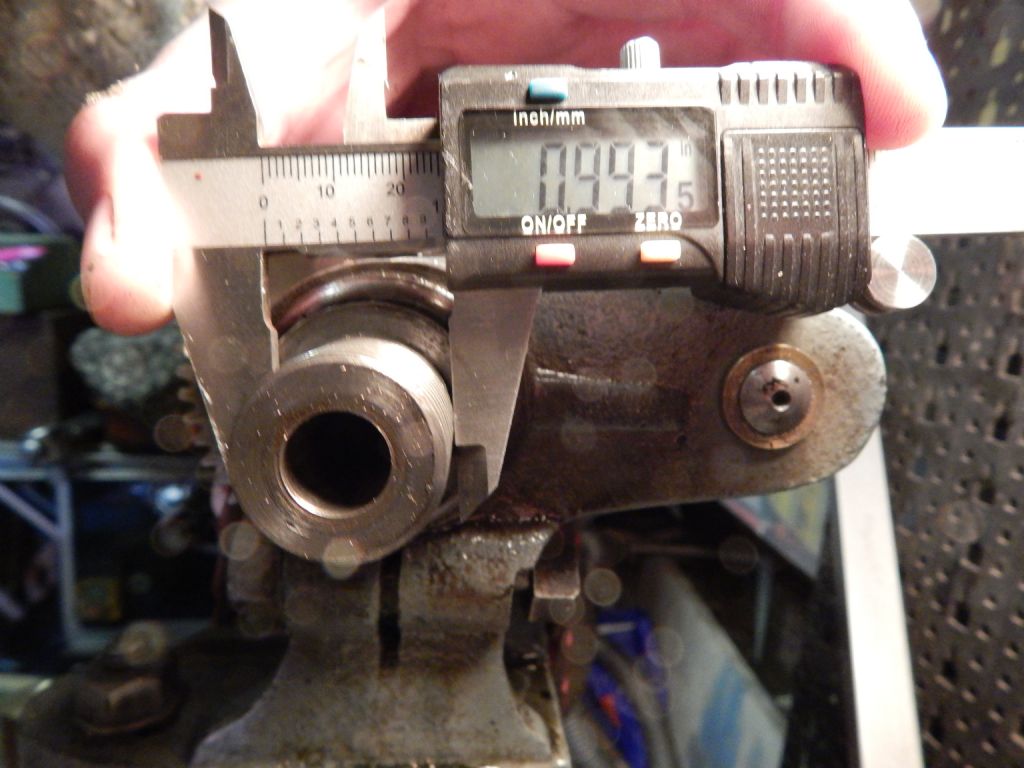

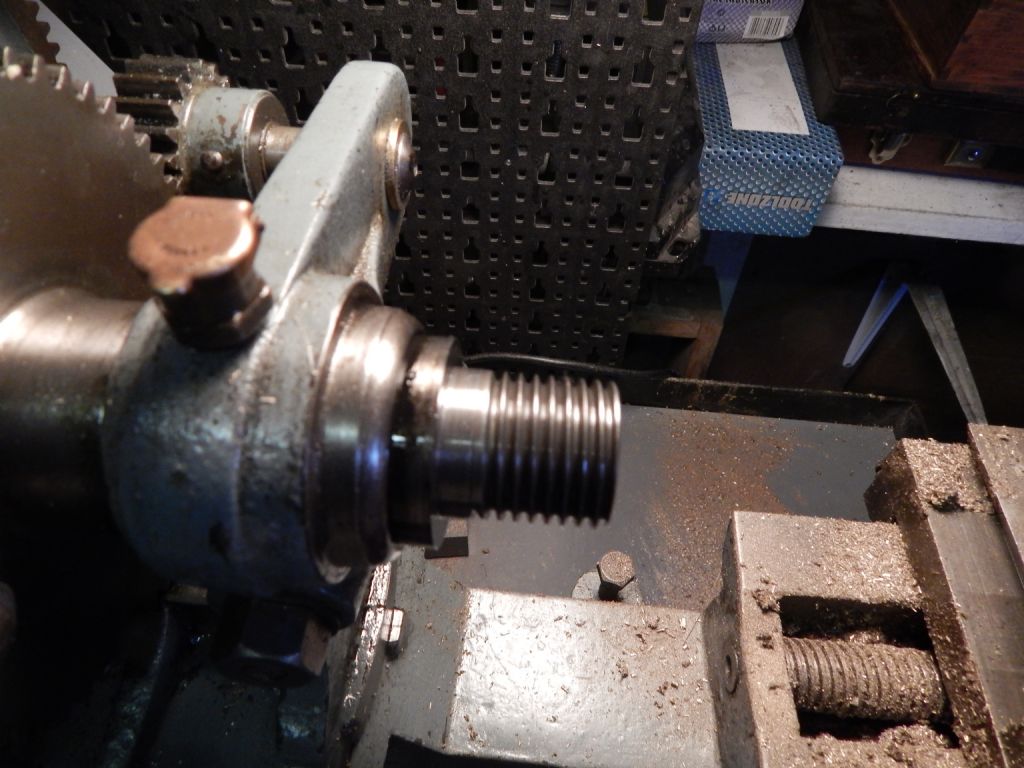

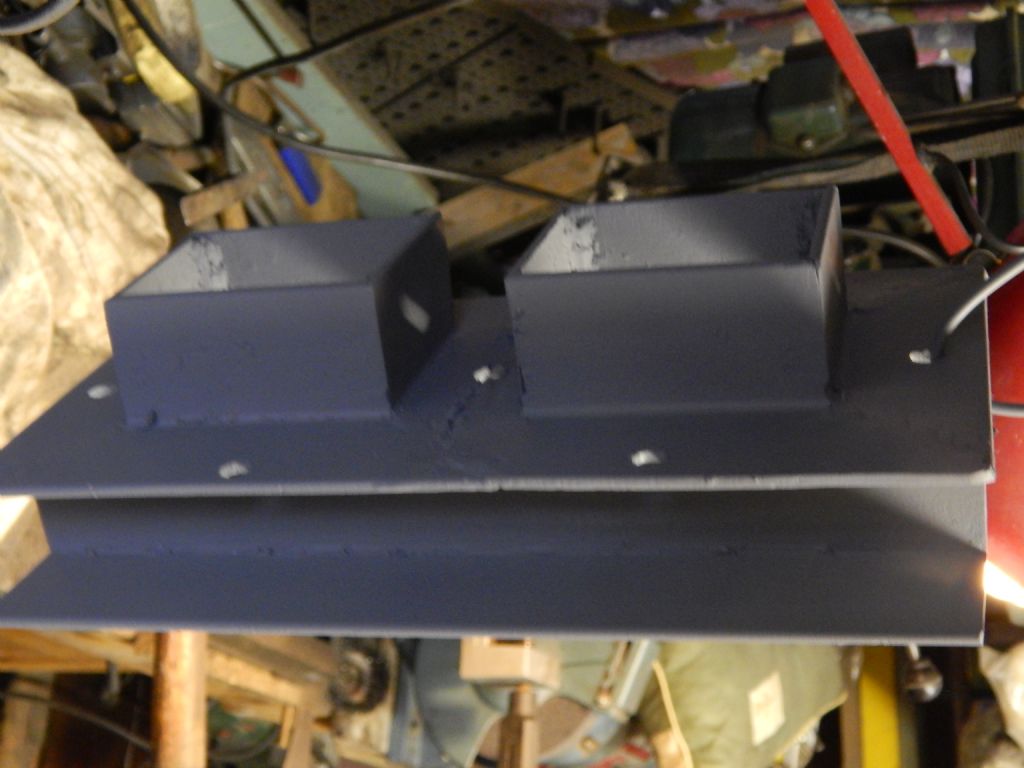

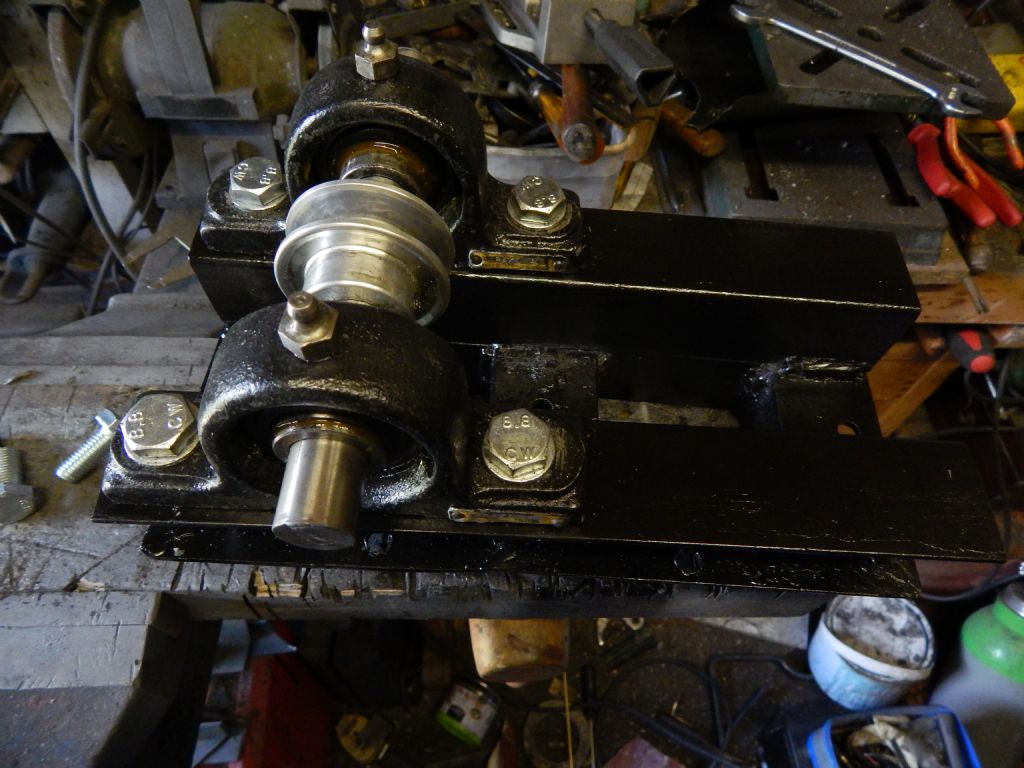

Hi everyone . Finally received my small pulley today which was supposed to be 19mm 3/4" , hmm had a struggle with this to enlarge this initially to make it the same size as my 3/4 " shaft. Tried everything and eventually wrapped sandpaper around a drill until it was tight and rotated it until it was large enough to just fit. Mounted all of this onto my frame

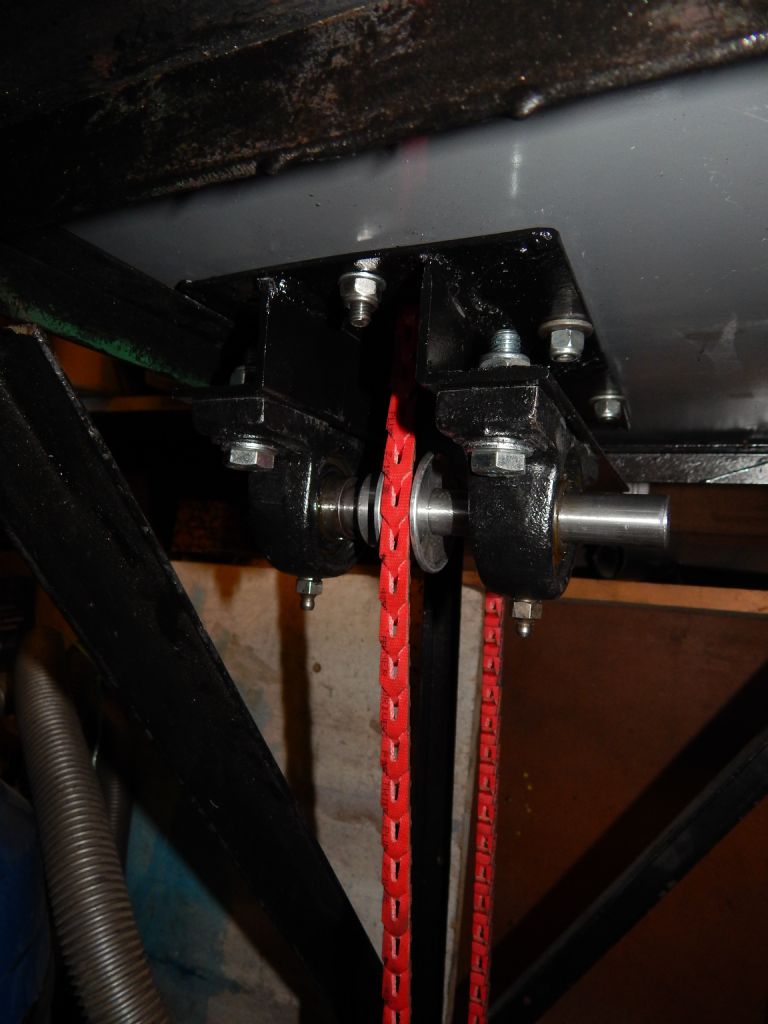

.I then mounted this back onto the bottom of the table and put the belt back on.

My inverter had arrived and I had wired it up to the motor and already had it running the motor. I tried this with the lathe connected and started hearing a wine and the lathe was hunting in speed. I ran tech and they changed my amps set in the drive from 1.9amp on the motor to 20amp. This then stopped the hunting.. The tech then asked me for my chuck size which is 3.5 and the size of my drive pulleys which are both around 4" . I get the impression they was saying this drive is not powerful enough to run this lathe. Its a 0.37kw drive and motor. Does anyone have any knowledge of this as they said this should be ok?

Martin Newbold.

Would post a vid but not sure how to

Would post a vid but not sure how to