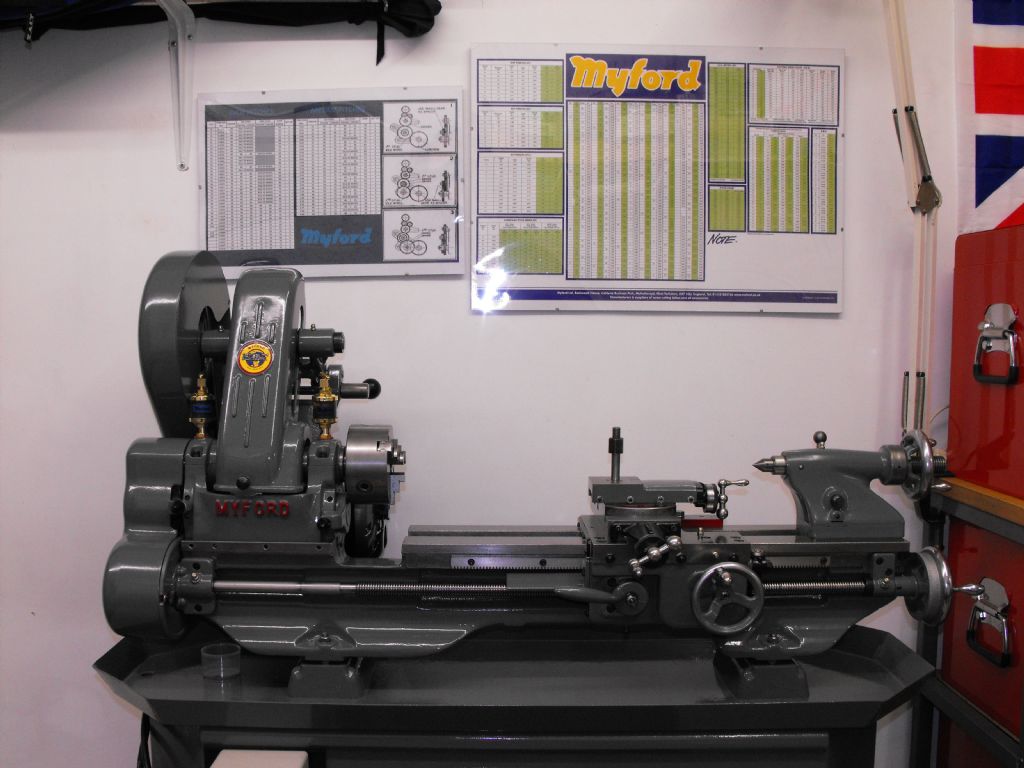

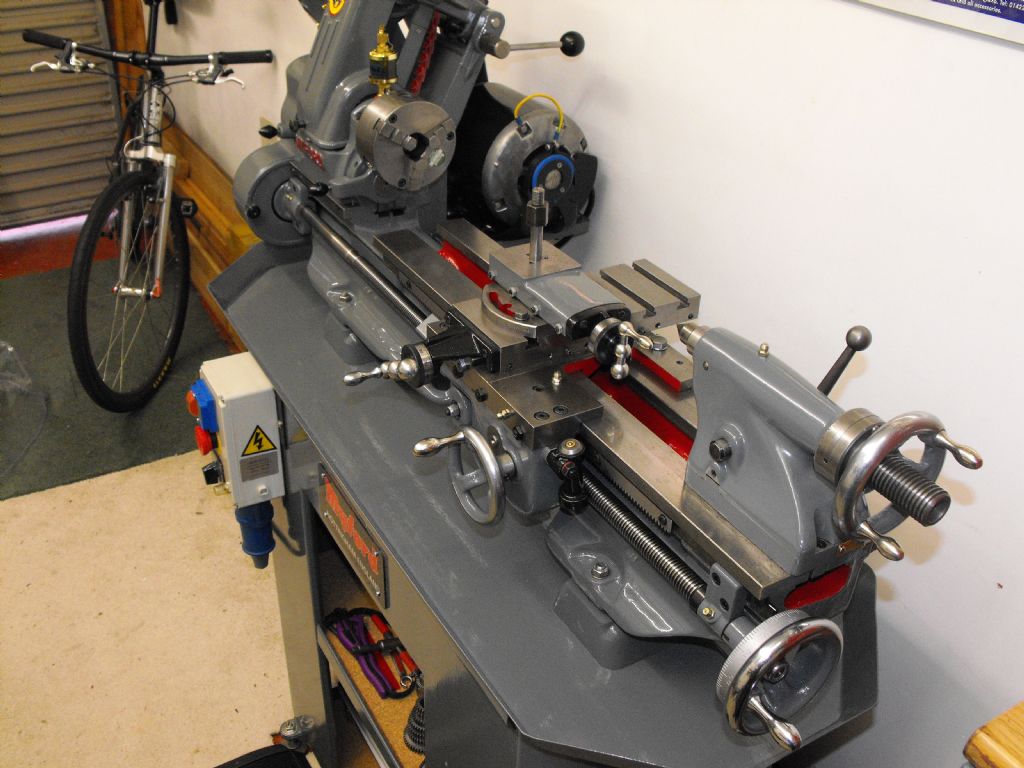

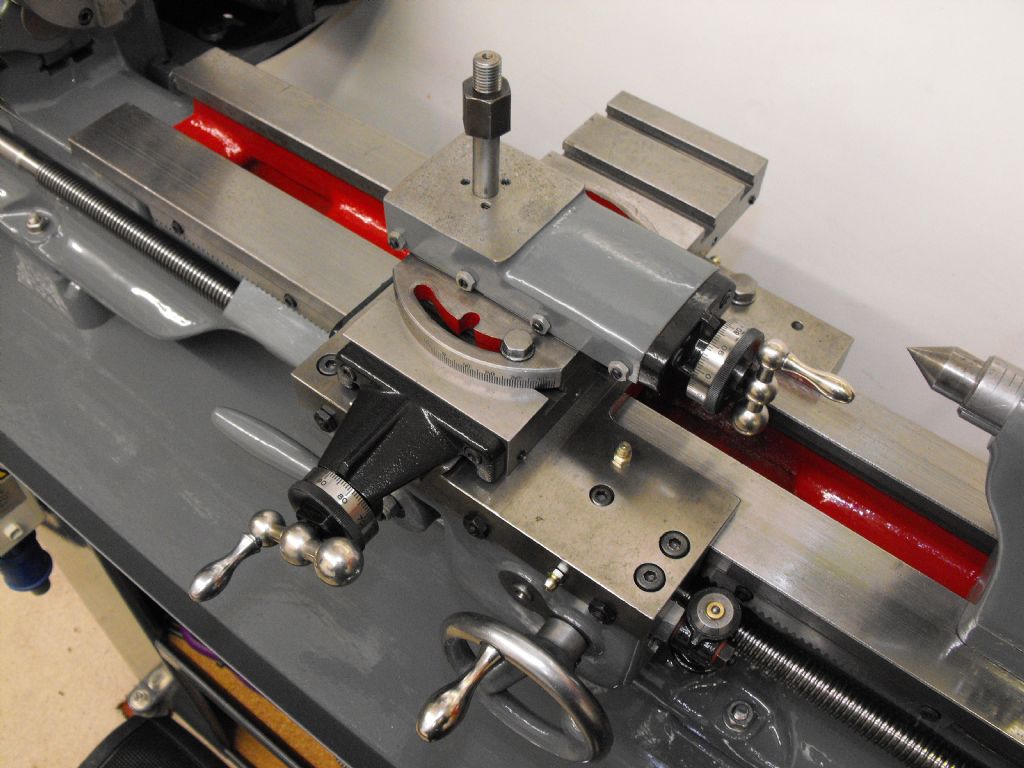

Hey there, so on the headstock question, yes it was removed. On refitting I stuck an MT2 test bar in the spindle and ran the clock up and down whilst sat on the saddle. Got it to within a 0.002" over 10" length after a while of gentle pottering.so was pleased with that. I appreciate though whilst cutting parts flex somewhat so you probably don't need to be quite so precise but I was brainwashed during my apprenticeship on being precise so can't beat it out of me. For the tailstock incidenlty, I just kept clock in same spot, and fitted test bar the other end and did the same. So in theory they should be centred on each other. When I get my toolpost, I can then do some cut tests as detailed in the myford book and adjust more if needed.

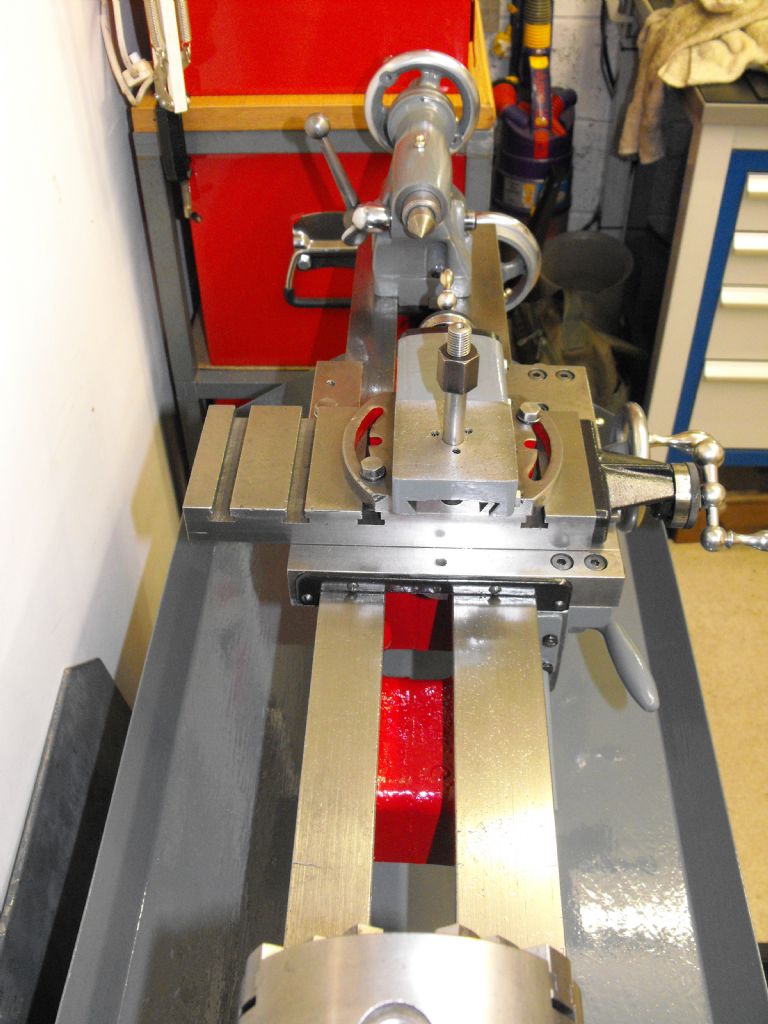

So for the rust I used I used dilute citric acid and then a brass wire brush on drill. For the slideways though I didnt want to be quite so aggressuve, so the bad spots I lightly used fine wirewool, then metal polish(Peek) on a drill mop. There wasnt any deep rust or pitting so did'nt feel it needed a regrind and now having rebuilt the saddle and reshimmed it, there is no play up/down or front/back along the bed length so am happy its all good. I'm not an expert but if I have no tight or sloppy areas of play, it must be good right? That was my thinking anway.

Yes had quite a bit of bubbling, so I just chipped those parts off, cleaned the surface & filled with car filler, sanded back flush with the good paint then primed over the top before resparying.

Hope that helps.

Phil Boyland.