I have found two issues when trying to fit some of the imported holders to my original post and both stop theholder locking firmly to the post.

The first is the easiest to cure. The holder should only be making contact with the two "V" sections at the end of the holder and there should be a gap where the "tee slot" is drawn in towards the post, in the photo you can see a 0.015" feeler gauge in there.

On some holders the holder makes contact where the feeler gauge is before the ends do so the holder will wobble about. Easy remedy is to hold these surfaces against a linisher or belt sander to thin them enough that they no longer make contact first.

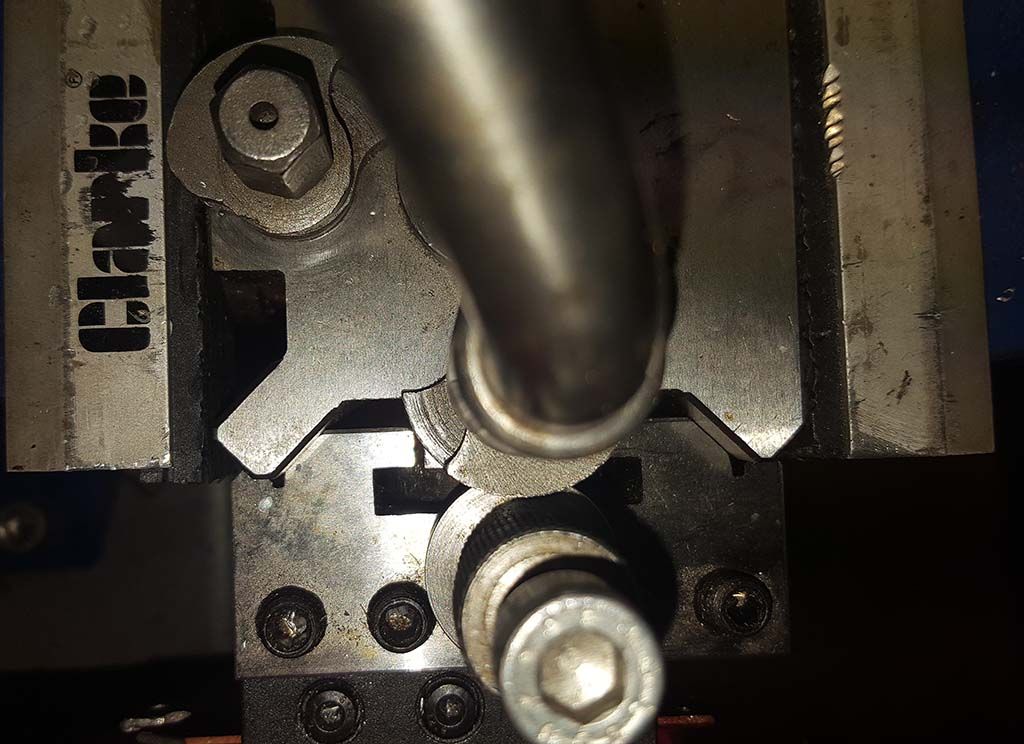

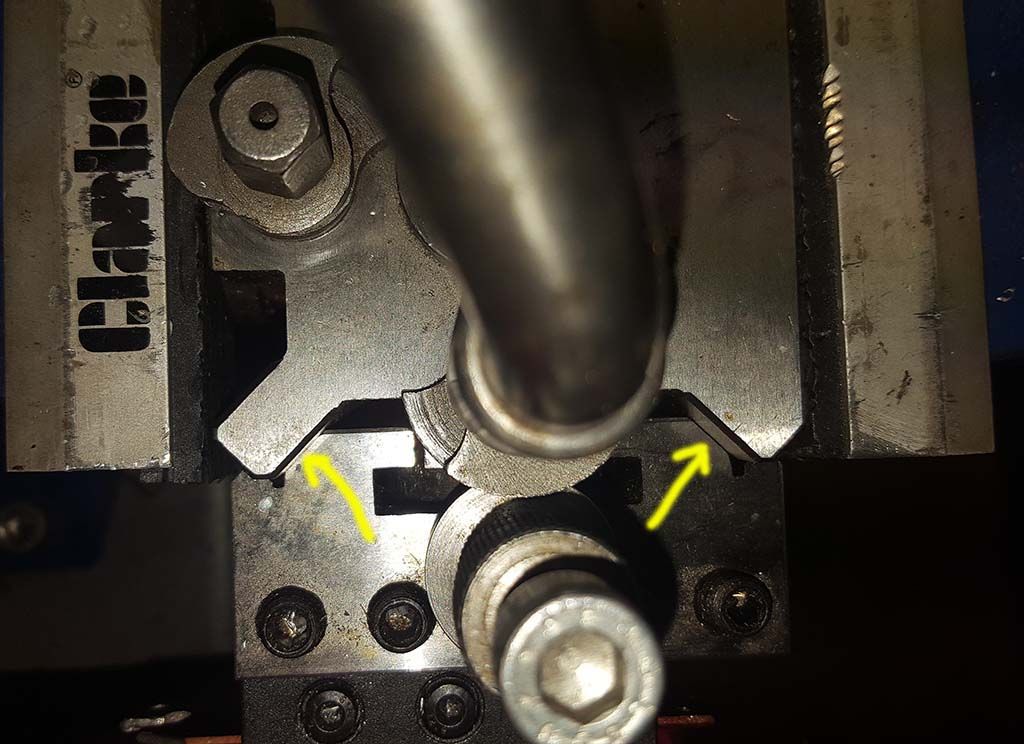

The other problem is that the inside edge of teh "tee slot" is too far from the post which prevents the cam actuated clamp from rotating far enough to get it into the sweet spot where it holds firm. This photo shows how far the clamp rotates on an original holder

And this how far on a thick one, probably 50-60 degrees less

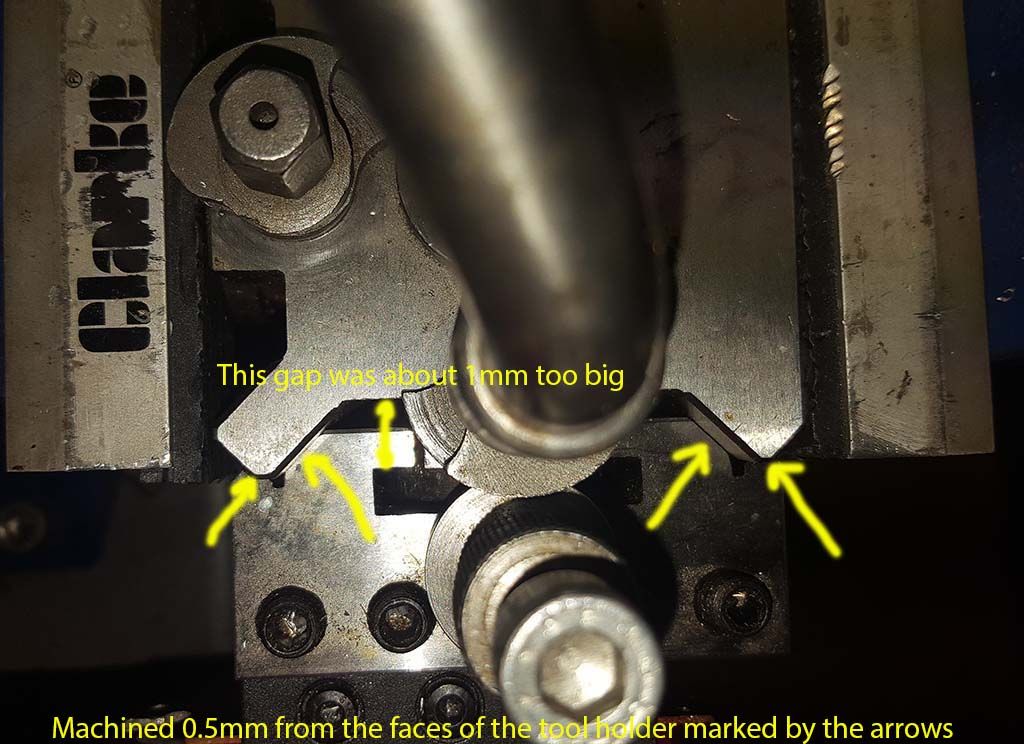

This shows where the problem is, original holder 0.127" and import 0.142"

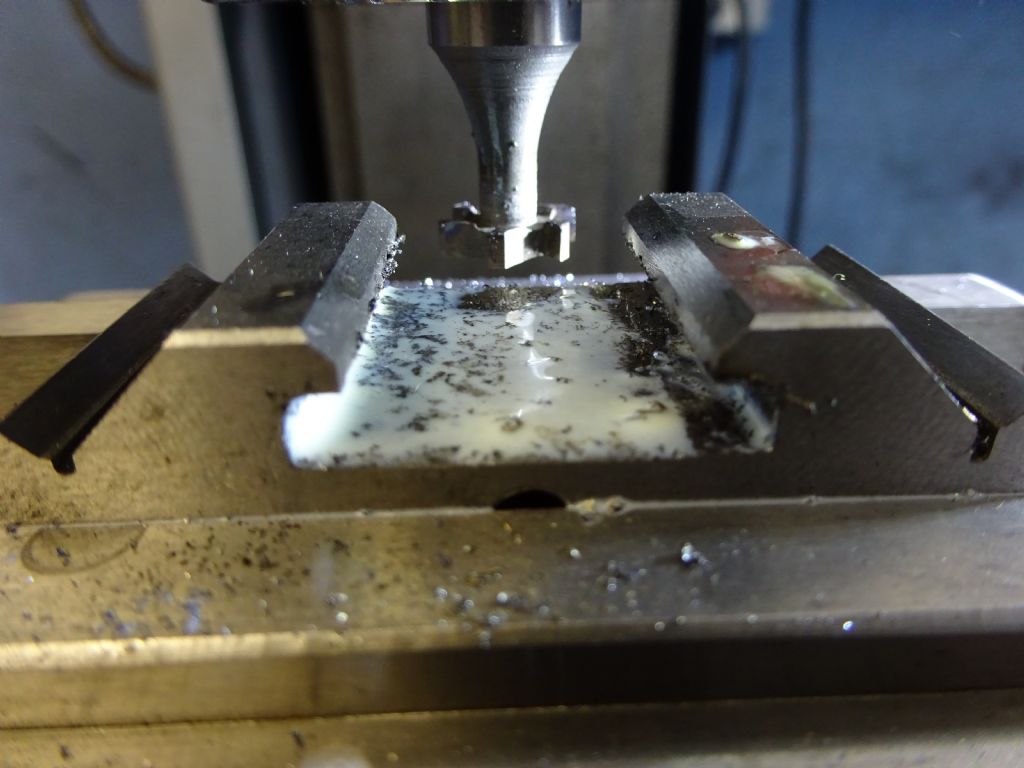

Not such an easy fix and it will depend on how hard your particular holders are, ideally a carbide ciutter but at a pinch a sacrificial HSS one can be used to get under the tee to thin it down.

Edited By JasonB on 13/10/2018 20:20:54

Tomfilery.