Hi Iain

Never had one of those exact assys from a Warco mill apart but here's a couple of ideas to try to get the shaft out:

1. warm the housing sides around the shaft to expand the metal around the pin with a propane torch on highest power, and then try pushing the pin out. Support the housing side as close to the pin as possible. Sockets from a socket wrench set are handy for this. If you have an arbour press I'd suggest using that rather than hammer and drift.

2. What normally fits in the pin's threaded hole? if nothing normally does, it suggests it might be for jacking out the pin. Again a socket can be used, with a capscrew passed through the drive square hole, a washer under the head. This arrangement keeps the pulling force local to one side of the housing.

3. If all else fails the pin could be carefully drilled out and a new one made from o-1 steel or something like it.

4. HPC gears in UK have been mentioned many times in the forum as a supplier of new gears.

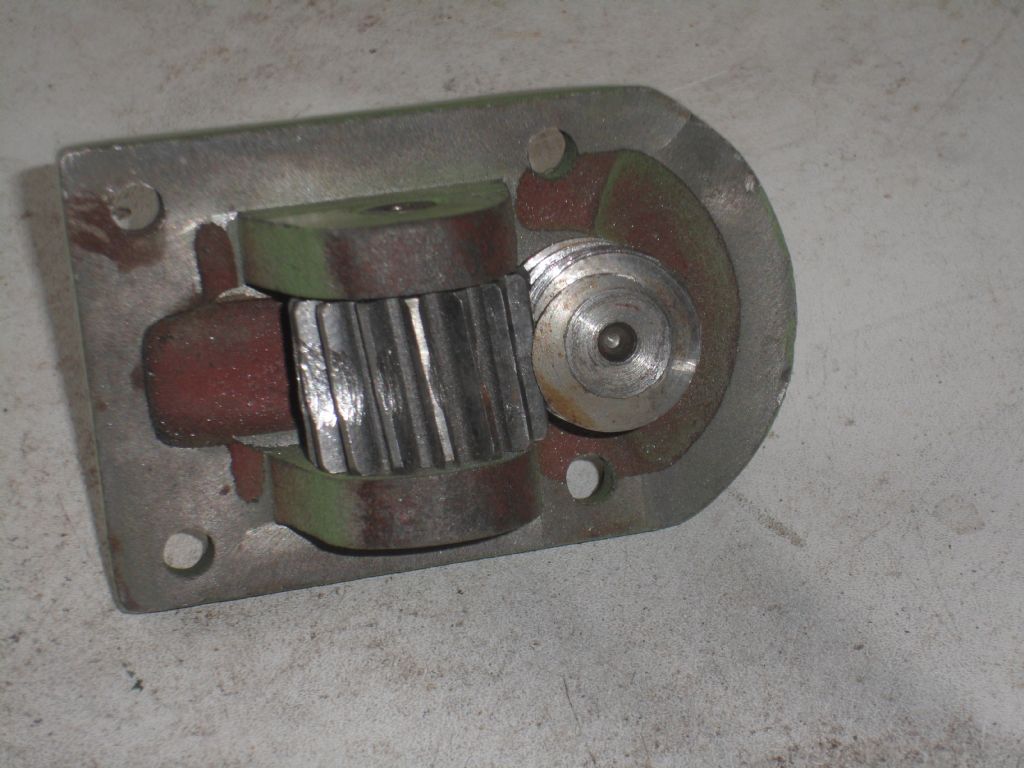

5. The assy shown in your pictures looks bone dry. If it has been operated dry this would partly explain the wear. I'd recommend a good coating of heavy extreme pressure grease, renewed yearly, to keep the replacement gears operating smoothly. Even axle or chassis grease from a car part store would be better than dry.

Good luck with it.

Edited By Jeff Dayman on 21/10/2018 14:51:14

larry phelan 1.