Posted by Lynne on 06/05/2016 22:41:36:

I have been following this thread with interest, as I am thinkig of buying a Rotary Table.Vertex were in the frame,but in the light of comment, I am looking at alternatives. Arc prices are a bit eye watering by comparison, and they are supplied with mounting plate for Chinese chucks, and its Hobsons choice. They (Arc) did put it to me that it was only a small element of the total cost, which to me is saying it would'nt be any cheaper if they were to supply minus the plate. Warco have quite a good range , but they give no indication as to the origin of the tables, and I would be interested to hear from forum members who may have more knowledge of Warco products than I. Finally, is it a major machining op to marry up mounting plate to Rotary table and chuck, to achieve repeatable concentricity.. Lynne.

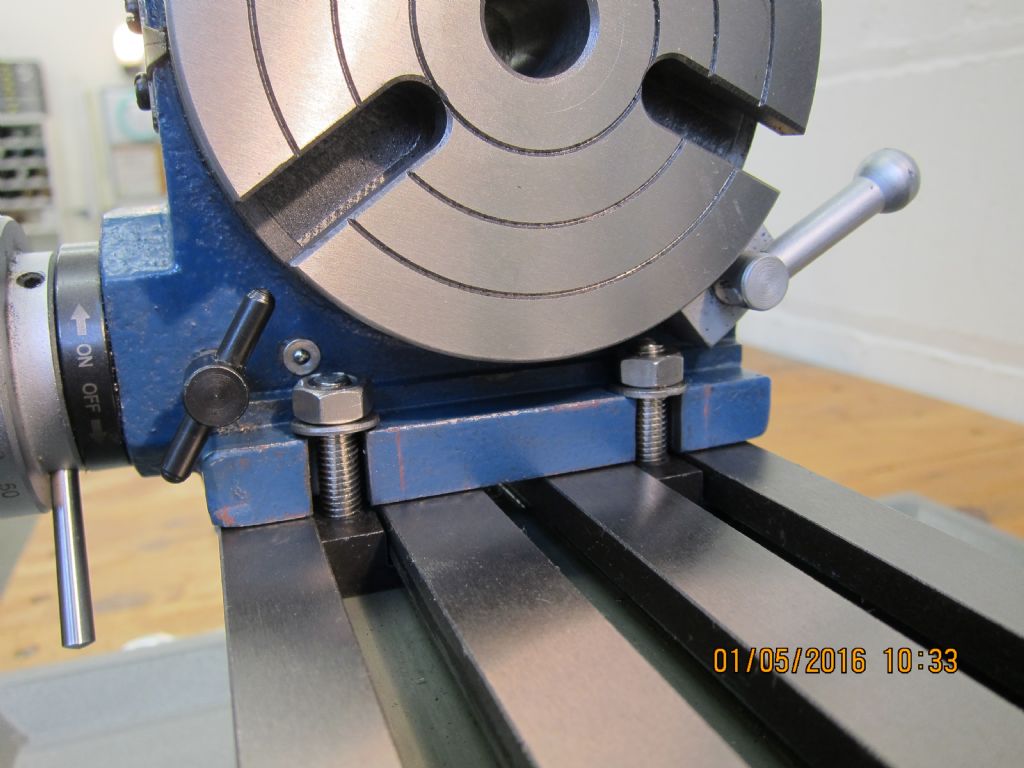

I recently bought the warco 5" model. I believe mine is probably from China . I found two manufacturers but the Sara Tools India ones had different hand wheel handles than mine which were like the Chinese ones.

**LINK**

Possibly made by these lot but ,couldnt be certain.

**LINK**

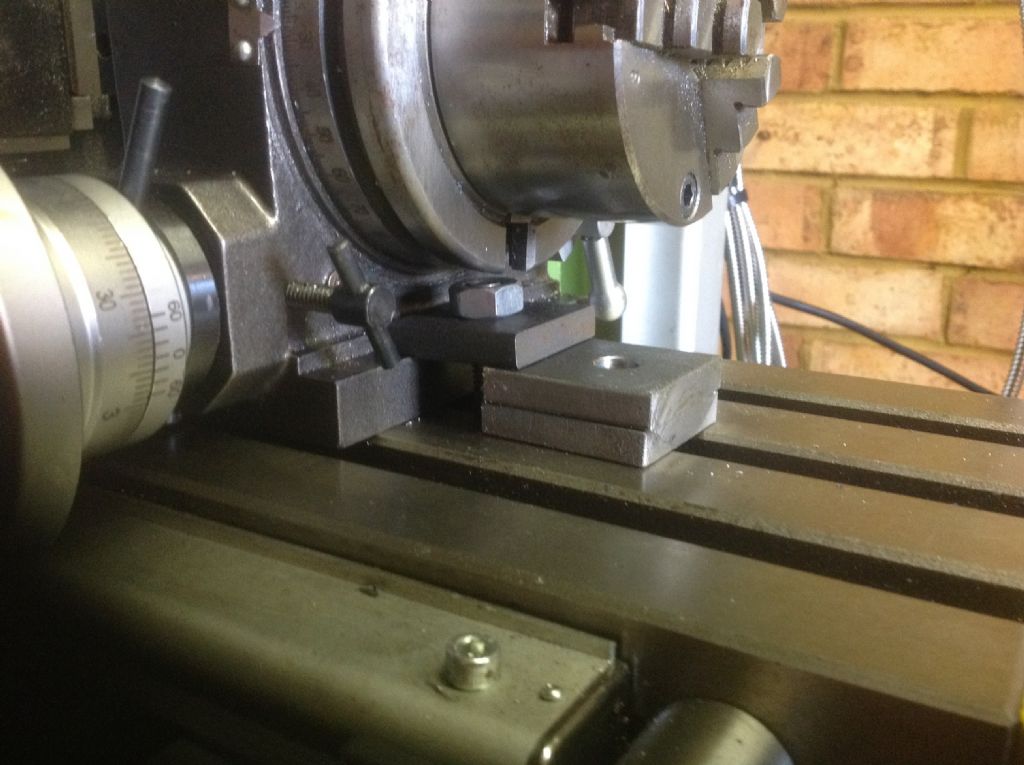

I found an old Mini lathe 32er collet chuck and have mounted this to the table.

I have centred it by buying a blank 2mt soft end arbor which fits in the middle of the table. I machined the blank end to just under 20mm and put a 20-19 collet in the chuck and placed it on the arbor end and tightened the chuck up. Then i can just tighten the bolts down to the table.

Then remove the collet and arbor and the chuck remains more or less accurately centre for most purposes.

Paul Lousick.