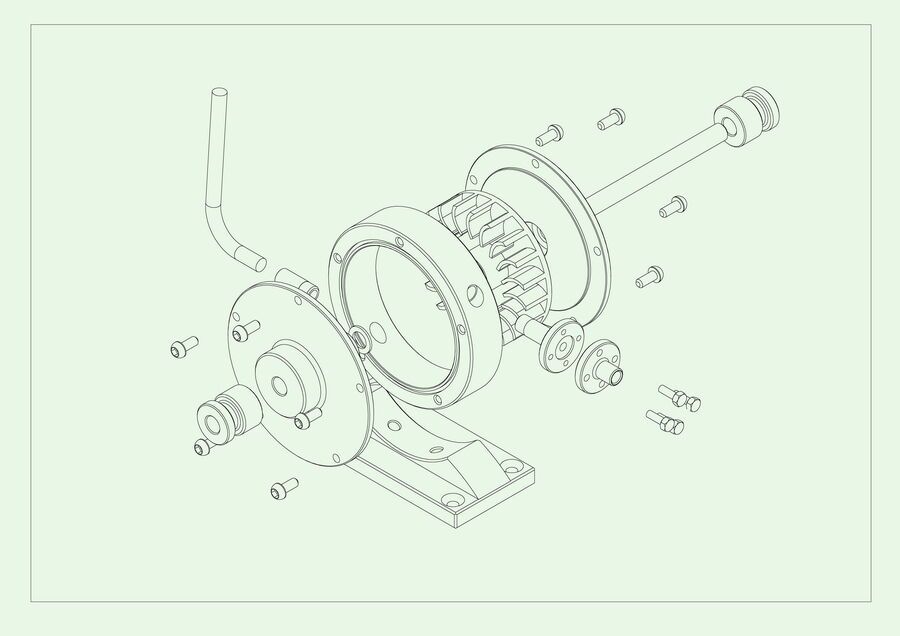

I glued Rotor 6 PLA shown in the last post to a shaft and ran it in Tangential Turbine 6 shown in the following drawing and spreadsheet. I made an error in guessing where to glue Rotor 6 PLA on the shaft which resulted in getting much higher compression on the spring than I wanted, but as you can see in the spreadsheet the performance wasn’t that bad for the first test. Normally I would run several tests to find the optimum position of the rotor in the housing and the best spring compression before adding the performance in the spreadsheet. When I disassembled the turbine to reposition the rotor on the shaft, I found that the extension of the rotor on its outer face had broken off. I mentioned in the last post that the rotor was designed to be cast in bronze and had several areas that were two thin for a material like PLA. I am in the process of trying to fix the rotor assembly but it will require enough changes that it will have to be called a new assembly.

The last few posts have been for turbines with rotors 3D printed by me from PLA. Now that I have learned some of the more important print settings and speeds to machine the PLA, I have been getting rotors that probably perform close to what I could obtain with rotors machined from metal. This allows me to try different ideas, small improvements, and combinations of improvements until I get the best performance I am able to obtain for the type of rotor 3D printed in PLA. I only show in this thread the best performance I have obtained for a given concept and often it takes many attempts. It took me a few attempts to make Rotor 6 PLA discussed in the quoted thread that explained the rotor needed to be designed for 3D printing in PLA. Rotor 6 PLA R1 shown in the following drawing and spreadsheet was redesigned to make it stronger and try some ideas to improve the performance. After trying a few different things Rotor 6 PLA R1 reached the maximum performance for all the ideas I could think of. You can see from the drawings and spreadsheets in the quoted post and this post the changes that were made and the resulting improvement in performance.

Turbine Guy.