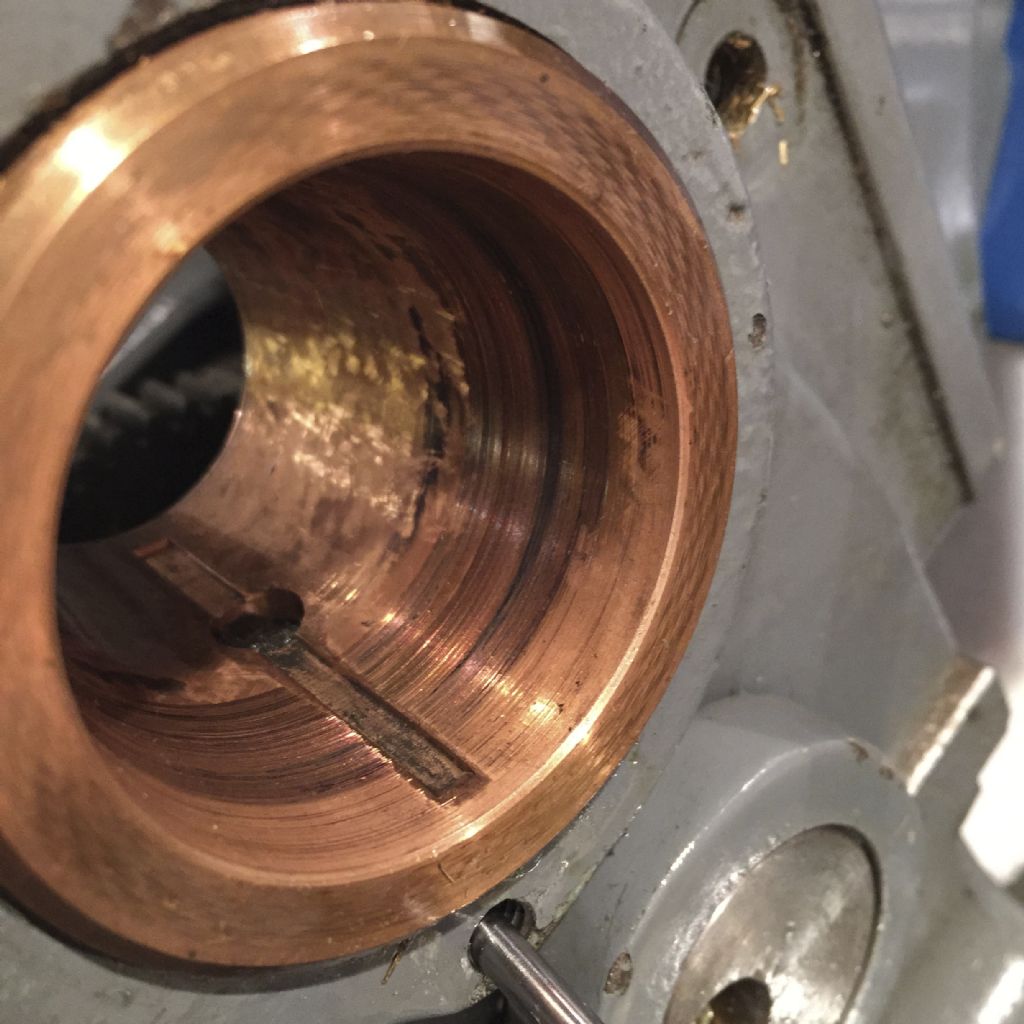

Hi, the latest so far; rather than have my lovely ML7R in pieces, I thought I’d put it all back together before I forgot what’s what and got busy with some other distraction…and during the process, adjust the spindle as per the instructions.

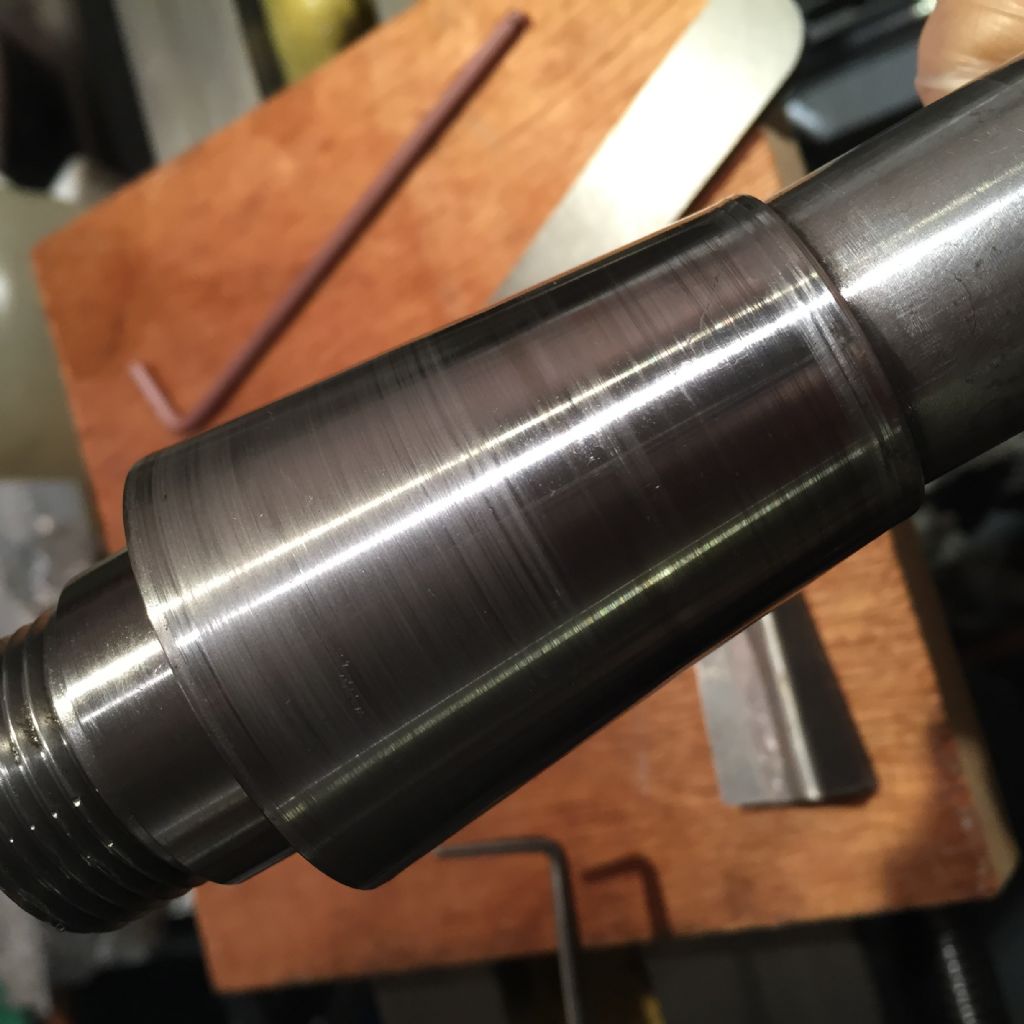

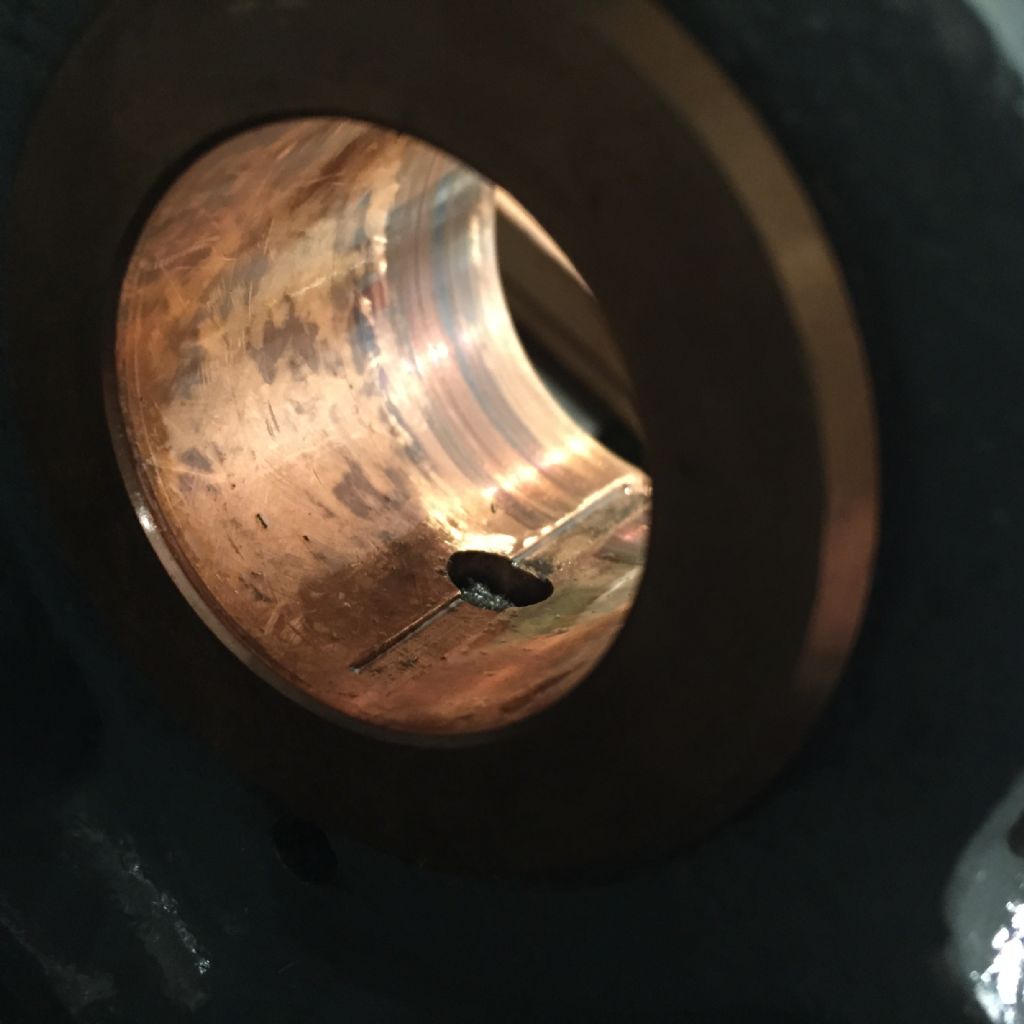

Success! (sort of), I’ve managed to adjust the spindle to two tenths over two thou’ of run-out which if you remember is better than the original reading of over eight thou’ of R/O…!

As you can imagine I’m very happy, despite it not being an acceptable tolerance, however it will do for now or at least until I can persuade someone to come and service it professionally.

To that effect I've recently (last two weeks), I've been trying to contact Darren Boden, the ex-Myford engineer, who for a price, would come out to service a Myford lathe. After leaving a voicemail and sending a couple of emails I'm yet to receive any sort of reply, his phone is never answered, just goes to voicmail. He could of course be on holiday but I just wondered if anyone had had recent contact with him and if he's still running his business? Would be good to know so I can try another avenue.

Thank you all for all your technical advice, whimsy and support.

Cheers, Jonathan

Ajohnw.

My Boxford appeared on ebay so I never bought one.

My Boxford appeared on ebay so I never bought one.